An on-line monitoring system and method for industrial waste gas based on fiber grating gas sensor array

A gas sensor and fiber grating technology, which is applied in the field of industrial waste gas online monitoring system based on fiber grating gas sensor array, can solve the problems of high investment in disposable equipment, difficult online monitoring technology of industrial waste gas discharge, and fragile consumables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

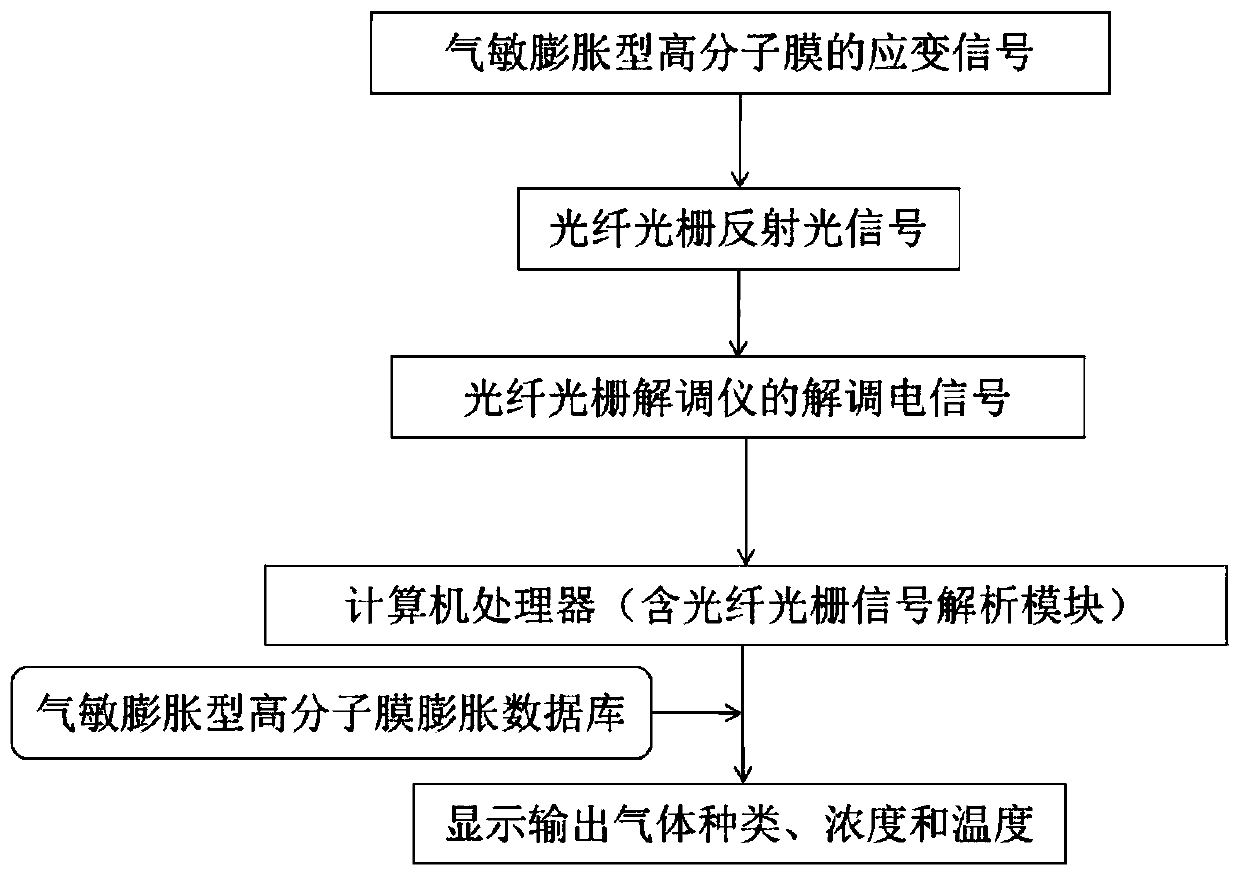

[0123] Fiber Bragg Grating is a strain- and temperature-sensitive sensing element, which can realize the measurement of dozens of strain or temperature nodes by a single optical fiber. It has high precision, small size, light weight, wavelength division multiplexing, long life and reliability With the advantages of high performance, corrosion resistance, and long transmission distance, it can realize the measurement of various parameters such as strain, stress, and temperature. Therefore, the application of fiber grating sensing technology to gas on-line monitoring can meet the special requirements of long-term and low-cost on-line monitoring of industrial waste gas. In this embodiment, a fiber grating with a diameter of 80 μm is selected.

[0124] This embodiment provides an online monitoring system and method for acetone gas concentration changes in a painting workshop.

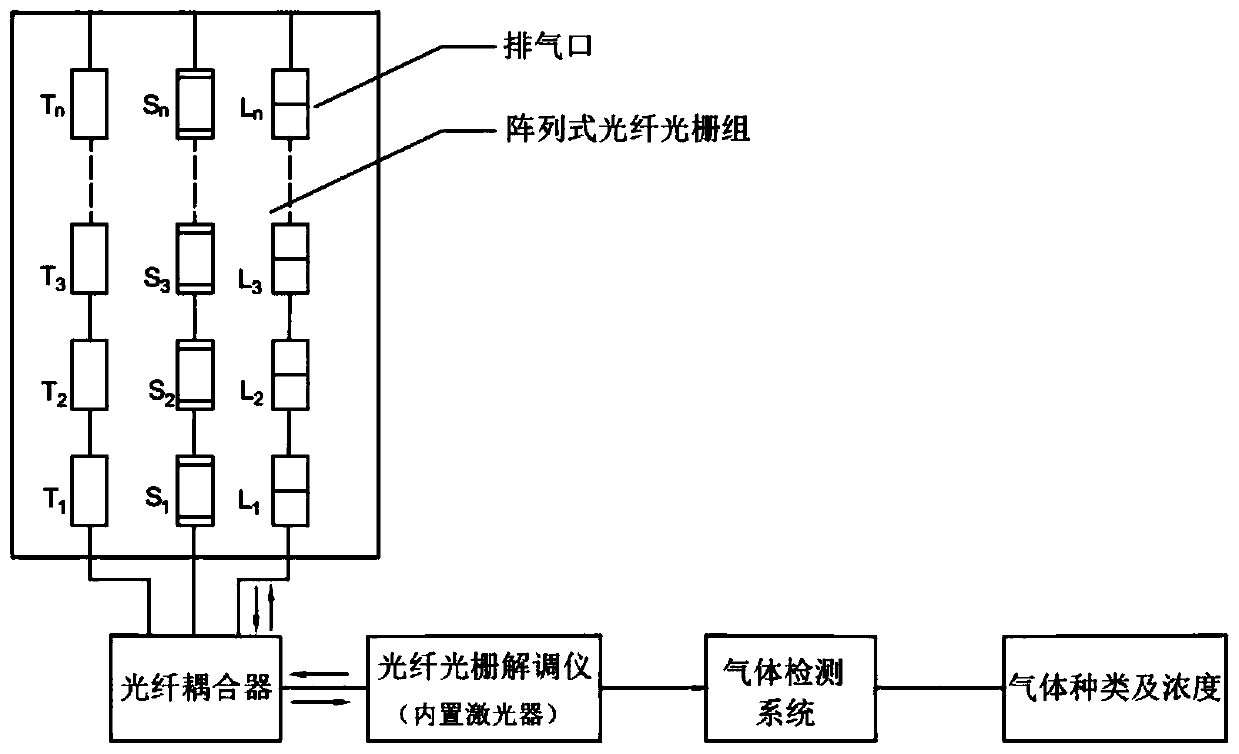

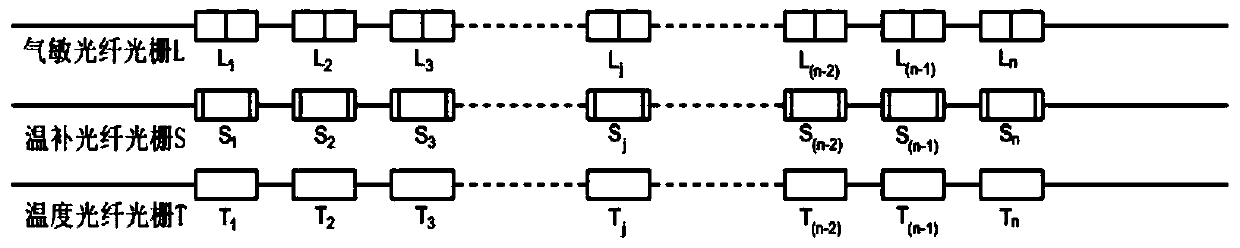

[0125] Such as figure 1 As shown, the system includes: an array fiber grating sensor, a fiber coupler,...

Embodiment 2

[0134] In this example, the gas-sensitive expansion characteristics of fiber gratings with a diameter of 80 μm / polyurethane film with a thickness of 30 μm and fiber gratings with a diameter of 125 μm / polyurethane film with a thickness of 30 μm to acetone gas were studied respectively. The modulus of the polyurethane film is controlled on demand by adjusting the ratio of the soft segment to the hard segment in the polyurethane macromolecule and the amount of nano fillers. Figure 5 It is the relationship curve between the elastic modulus and the theoretical elongation of the polyurethane film when the fiber grating produces an axial tensile strain of 0.001%. It can be seen that the fiber gratings with diameters of 80 μm and 125 μm produce the same axial strain. When the modulus of the polyurethane film is the same, the polyurethane film coated with the outer layer of the fiber grating with a diameter of 125 μm needs a larger deformation, that is, the fiber grating The smaller t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com