Camellia fruit shelling system

A technology of camellia fruit and skeleton plate, which is applied in the direction of shelling, filtering, and grilling, can solve the problems of tea seed damage and increase the sorting process of shell seeds, so as to reduce the workload, increase the wide adaptability, and improve the cleanliness. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

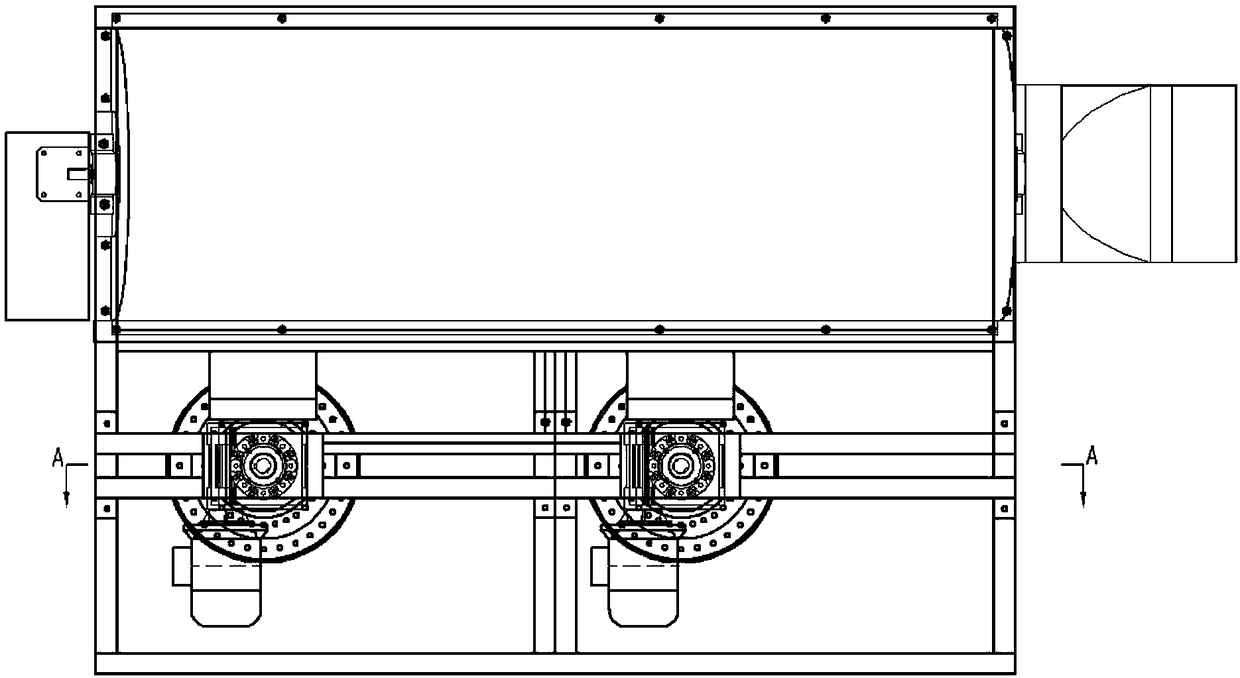

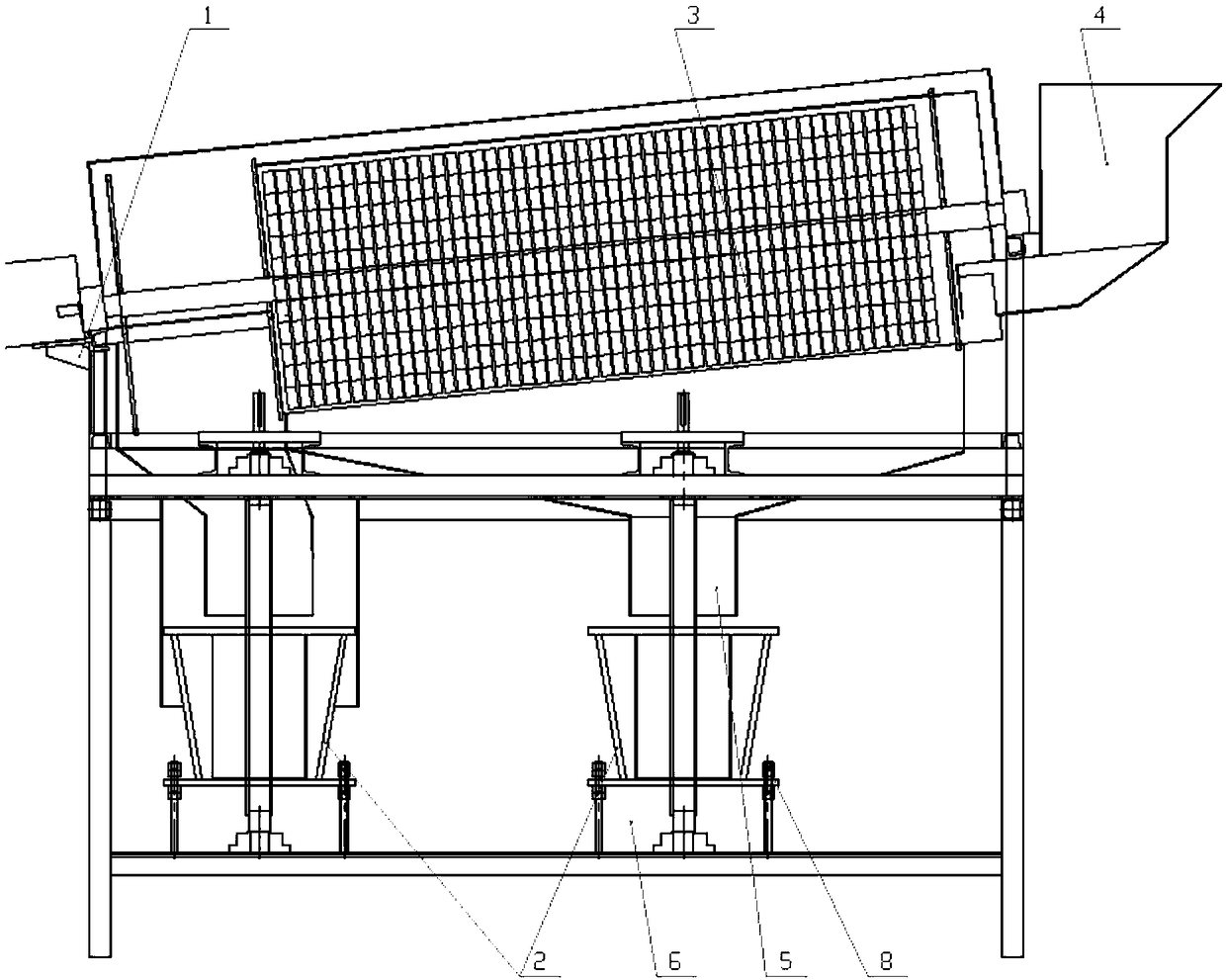

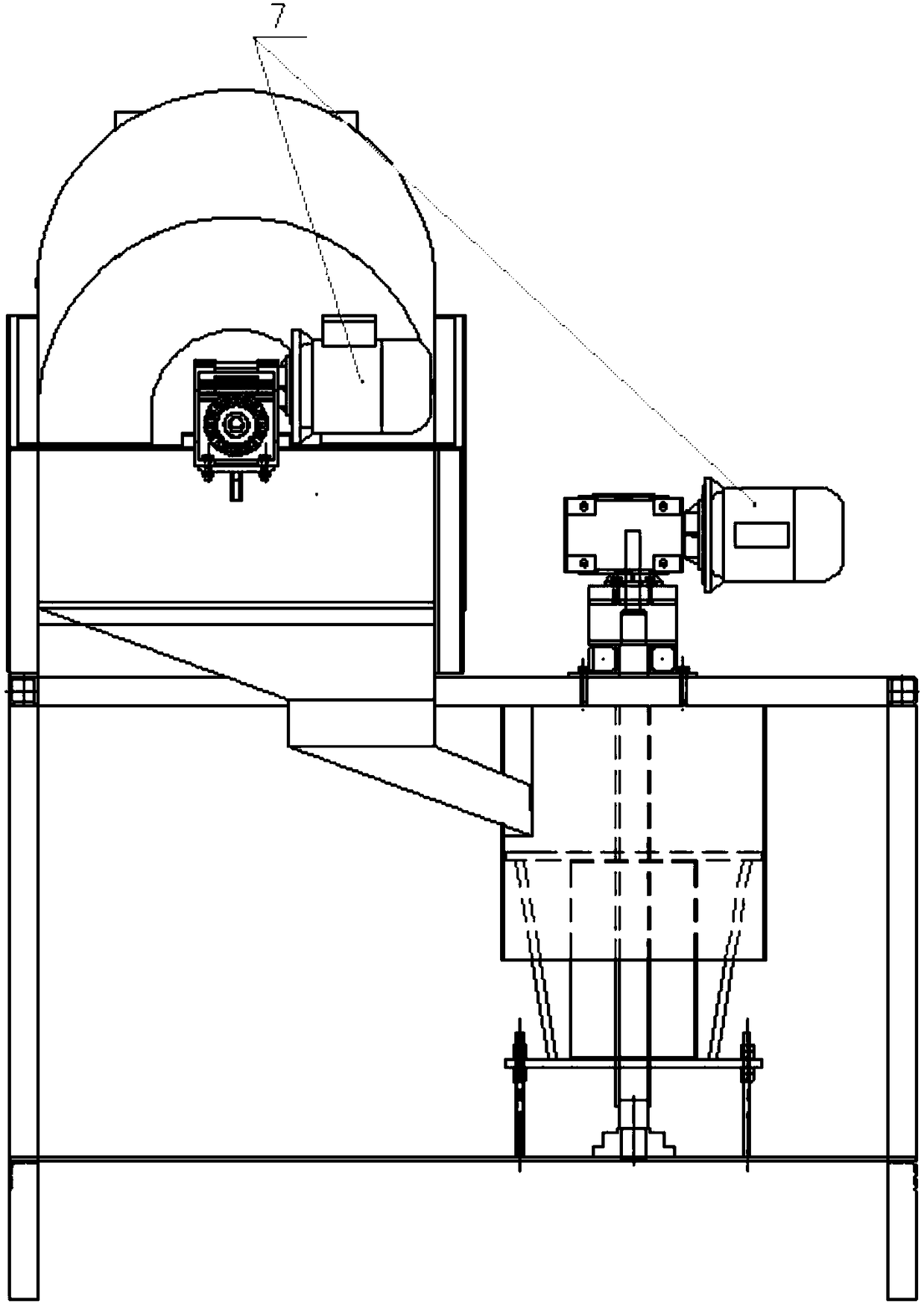

[0032] Such as Figure 1-3 , the camellia shelling system shown includes a frame 1, a squirrel cage sieve 3, a shelling unit 2, a vibrating screen and photoelectric color sorting equipment. The shown squirrel cage sieve is arranged obliquely on the top of the frame and driven to rotate by the corresponding power system 7, the shelling unit is arranged below the squirrel cage sieve, and the high end of the squirrel cage sieve is provided with a feeding port 4 communicating with the squirrel cage sieve , the squirrel cage sieve includes 2-3 grade sieving units, in the present embodiment, the squirrel cage sieve includes 2 grade sieve units, the bottom of each grade sieve unit is correspondingly provided with a graded outlet 5, each graded outlet Correspondingly, a shelling unit is provided. Such as Figure 4-8 , the shelling unit includes an outer cylinder 23 and an inner cylinder structure 22, the outer cylinder is inverted conical and vertically arranged, and the side wall o...

Embodiment 2

[0037]The difference between this embodiment and Embodiment 1 is that the outer cylinder is connected to the frame through a lifting structure 8, and the lifting structure can be an air cylinder, an oil cylinder, an up and down reciprocating mechanism, etc. In this embodiment, the lifting structure includes adjusting screws and adjusting nuts distributed on both sides of the bottom frame plate, the bottom frame plate is connected to the frame through the adjusting screw, and the adjusting screw passes through the bottom frame plate and is connected to the bottom frame The plate is slidingly socketed, and the bottom of the bottom skeleton plate is supported by an adjusting nut threaded with the adjusting screw rod. The height of the outer cylinder can be adjusted by rotating the adjusting nut to different heights of the adjusting screw rod. There is an anti-loosening nut threadedly connected with the adjusting screw above the bottom frame plate, and the bottom frame plate is cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com