Amorphous high-entropy solder alloy for brazing tantalum Ta1 and 1Cr18Ni9 stainless steel and preparation method thereof

A 1cr18ni9, high-entropy alloy technology, applied in the field of amorphous high-entropy alloy solder and its preparation, can solve problems such as cracking and difficulty in obtaining, and achieve excellent strength, easy control, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The amorphous alloy solder foil obtained by the above-mentioned preparation method, when assembling the sample joint of brazing tantalum / steel, first place the foil between the tantalum to be welded and the steel to be welded interface, and then vacuum The brazing method heats, heats, cools and solidifies the assembled joints to realize the brazing of tantalum / steel.

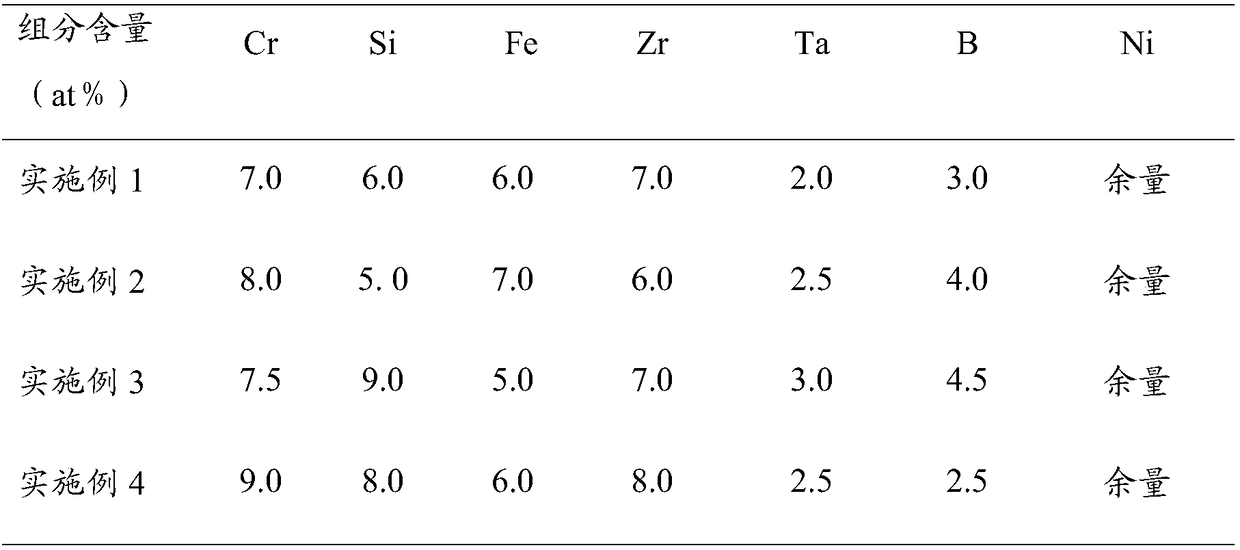

[0026] Table 1 is the solder composition distribution table of four embodiments of the present invention

[0027]

Embodiment 1

[0029] The quality of the high-purity metals of each component was determined according to the molar percentages in Example 1 in Table 1, and the above-mentioned brazing filler metal preparation steps were implemented, and the prepared amorphous alloy brazing filler metal foil was about 60 μm thick. Using the amorphous alloy brazing filler metal foil, Ta1 and 0Cr18Ni9Ti were brazed in a furnace at a brazing temperature of 1090°C and held for 5 minutes to obtain a joint with a shear strength of 210.0MPa.

Embodiment 2

[0031] According to the molar percentages in Example 2 in Table 1, the quality of the high-purity metals of each component was determined, and the above-mentioned solder preparation steps were implemented to prepare a state-of-the-art amorphous alloy solder foil with a thickness of about 55 μm. Using the amorphous alloy brazing filler metal foil, Ta2 and 0Cr18Ni9Ti were brazed in a furnace at a brazing temperature of 1070°C and held for 5 minutes to obtain a joint with a shear strength of 221.0MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com