A two-component cationic visible light initiator and its application in photocuring

A cationic, two-component technology, applied in the field of photopolymerization, can solve the problems of increased cost and environmental hazards, poor environmental safety, high equipment requirements, etc., and achieve the effects of shortening the induction period, fast initiation speed and low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

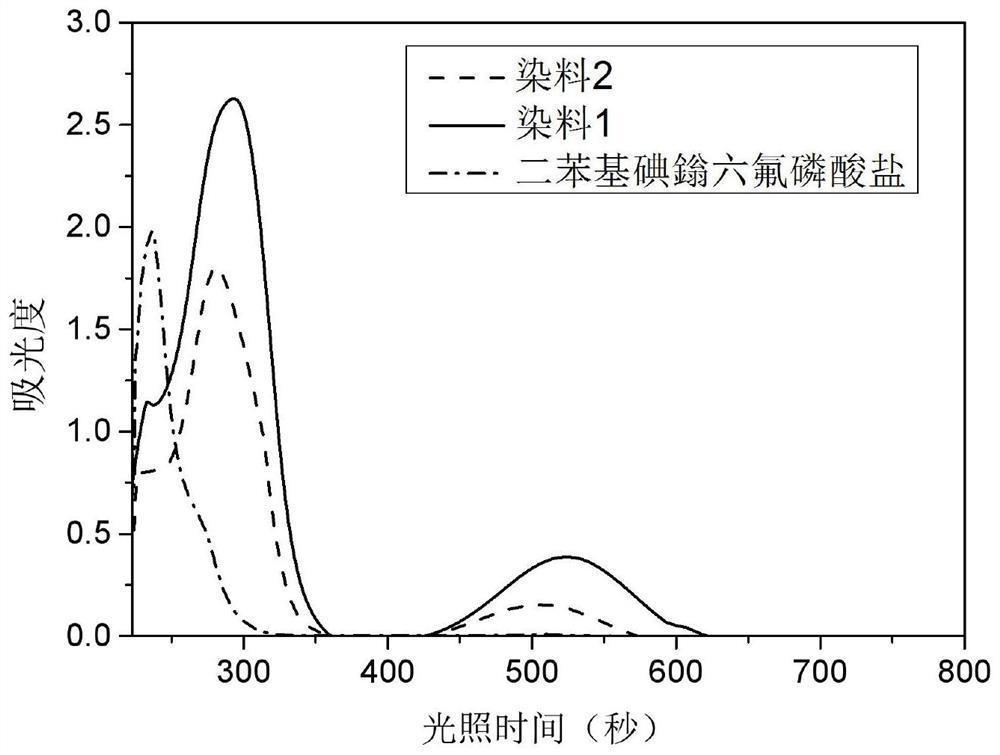

[0056] Embodiment 1 Preparation of organic dye 1 based on benzothiadiazole structural unit

[0057] Prepare the dyestuff preparation process shown in formula (III):

[0058]

[0059]Intermediate 1: Take a 500mL two-necked bottle, add benzothiadiazole (10g, 73.4mmol) and hydrobromic acid (100mL, 48%), and then dropwise add HBr (100mL, 48%) containing Br2 (220.3mmol) . After refluxing for 6h, a large amount of orange solid was produced, the reaction was stopped and cooled, and then neutralized with NaHCO3 saturated solution. Suction filtration, washing with a lot of water, the yield is 95%. Intermediate 2: Take a 100mL single-necked round bottom flask, add p-fluorobromobenzene (10mmol), KOH 20mmol and DMSO solution 20mL in sequence, and stir at room temperature. After 10 minutes, 10 mmol of p-fluoroaniline was added to the reaction system, protected from light, and the reaction was completed at room temperature for 2 hours. Tap water ethyl acetate (40mL / 20mL) extraction, ...

Embodiment 2

[0061] Embodiment 2 Preparation of organic dye 2 based on benzothiadiazole structural unit

[0062] Prepare the dyestuff preparation process shown in formula (Ⅳ):

[0063]

[0064] Intermediate 1 was synthesized as described in Example 1.

[0065] Intermediate 3: Prepared according to a method similar to that described in Intermediate 2, the only difference is that p-fluorobromobenzene needs to be replaced by p-methoxybromobenzene (10 mmol).

[0066] Dye 2: Prepared according to a method similar to that described in Dye 1, the only difference is that intermediate 2 (3.0 mmol) needs to be replaced by intermediate 3 (3.0 mmol).

[0067] 1H NMR (400MHz, DMSO) δ7.09–7.01 (m, 10H), 6.93–6.86 (m, 8H), 3.73 (s, 6H).

Embodiment 3

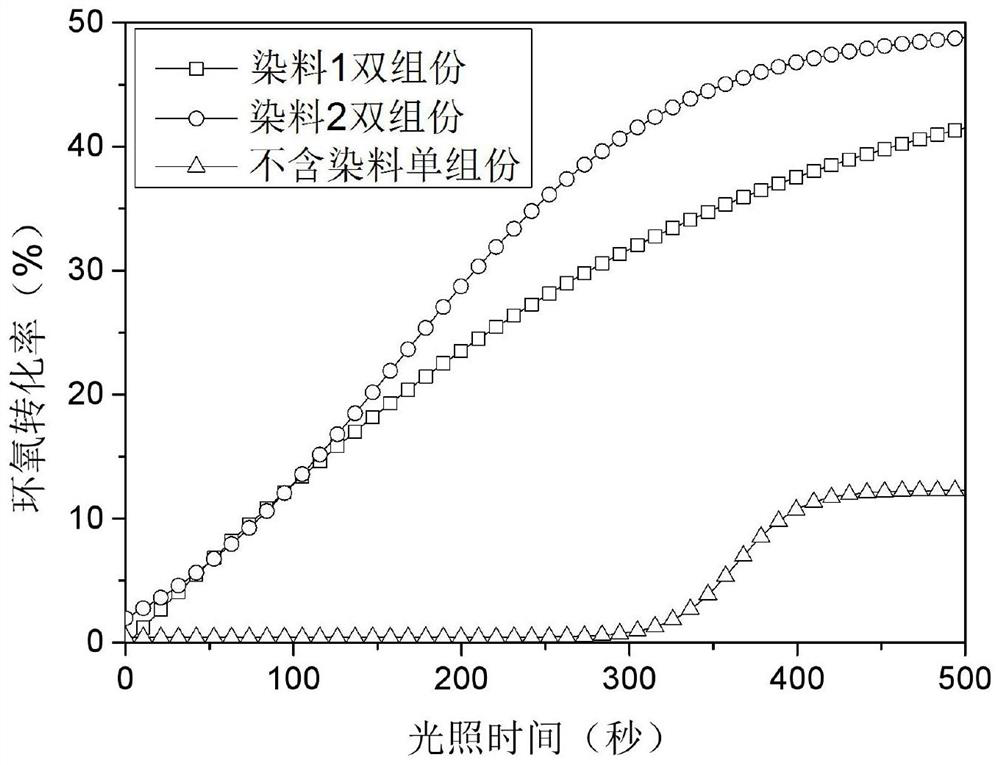

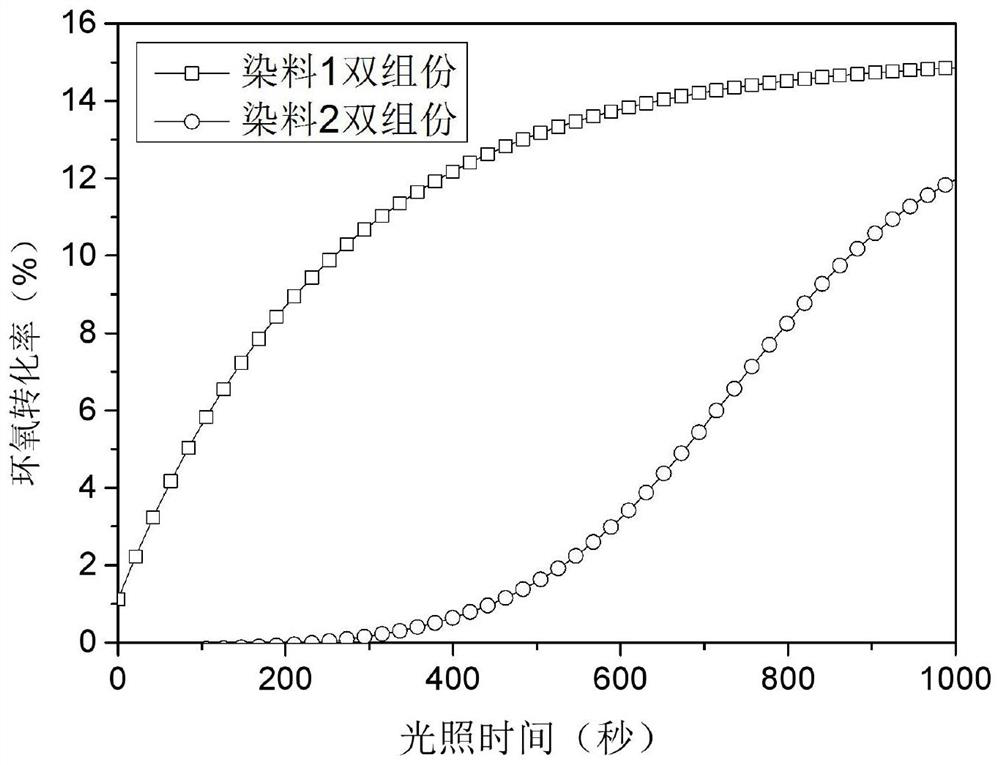

[0068] Embodiment 3 contains the preparation of dyestuff 1 curing sample

[0069] Weigh 0.2000g (0.469mmol) of diphenyliodonium hexafluorophosphate, add 0.0500g (0.092mmol) of the dye 1 prepared in Example 1 and place it in a brown bottle, then add 2mL of epichlorohydrin, stir fully to make The initiator was completely dissolved, and then 10 g of bisphenol A epoxy prepolymer E51 was added, and stirred evenly to obtain a cured sample, which was stored away from light.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com