Hydroxyl terminated polyester resin used for powder coating, preparation method and powder coating prepared from hydroxyl terminated polyester resin

A technology of hydroxyl-terminated polyester and powder coatings, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of poor weather resistance and unfavorable promotion, and achieve low cost, excellent water boiling resistance, and good leveling performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

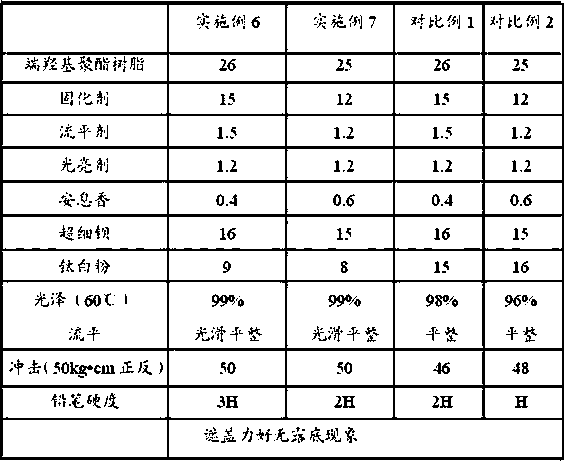

Examples

preparation example Construction

[0048] The invention also discloses a method for preparing a hydroxyl-terminated polyester resin for powder coatings, the specific steps are as follows:

[0049] (1) Weighing raw materials: Weighing raw materials according to the above ratio for later use;

[0050] (2) Esterification process: Add aromatic polyacids, polyols, branching agents and esterification catalysts into the synthesis reaction vessel. After sealing the kettle, gradually heat up the reaction in a nitrogen atmosphere, and then take samples for testing. The acid value is 5~ 10mgKOH / g;

[0051] (3) Vacuum process: add an antioxidant to the reactants obtained in the esterification process, and lower the temperature of the synthesis reaction vessel to 190~210°C, keep warm, vacuumize, and carry out the reaction at a vacuum degree of -0.096~-0.098MPa until the reactant reaches an acid value of 0.5~3mgKOH / g and a viscosity of 2800~3000mPa•s;

[0052] (4) Adding additives process: lower the temperature of the kett...

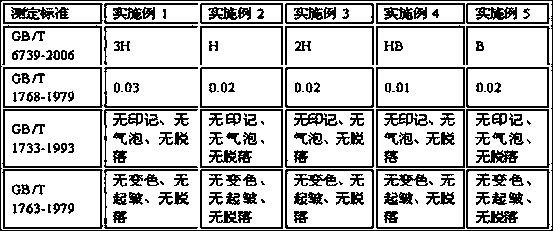

Embodiment 1

[0057] A hydroxyl-terminated polyester resin for powder coatings, which is prepared from the following raw material ratios: 32 parts of polyols, 46 parts of aromatic polybasic acids, 0.05 parts of branching agents, 0.1 parts of esterification catalysts, 0.12 parts of antioxidants, and inorganic pigments 0.05 parts, 0.22 parts of curing accelerator; the polyol is 2-ethyl-2-butyl-1,3 propanediol, the aromatic polyacid is terephthalic acid, and the branching agent is trimethylolpropane and trimethylol A mixture of ethane, and the antioxidant is a hindered phenolic antioxidant.

Embodiment 2

[0059] A hydroxyl-terminated polyester resin for powder coatings, which is prepared from the following raw material ratios: 35 parts of polyols, 46 parts of aromatic polyacids, 0.05 parts of branching agents, 0.12 parts of esterification catalysts, 0.11 parts of antioxidants, and inorganic pigments 0.06 parts and 0.24 parts of curing accelerator; wherein the polyhydric alcohol is neopentyl glycol, the aromatic polyacid is isophthalic acid, the branching agent is glycerol, and the antioxidant is a phosphite antioxidant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com