Production method for caramel colour

A production method, caramel color technology, applied in chemical instruments and methods, functions of food ingredients, azo dyes, etc., to achieve the effects of easy control, stable reaction process, and reduction of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

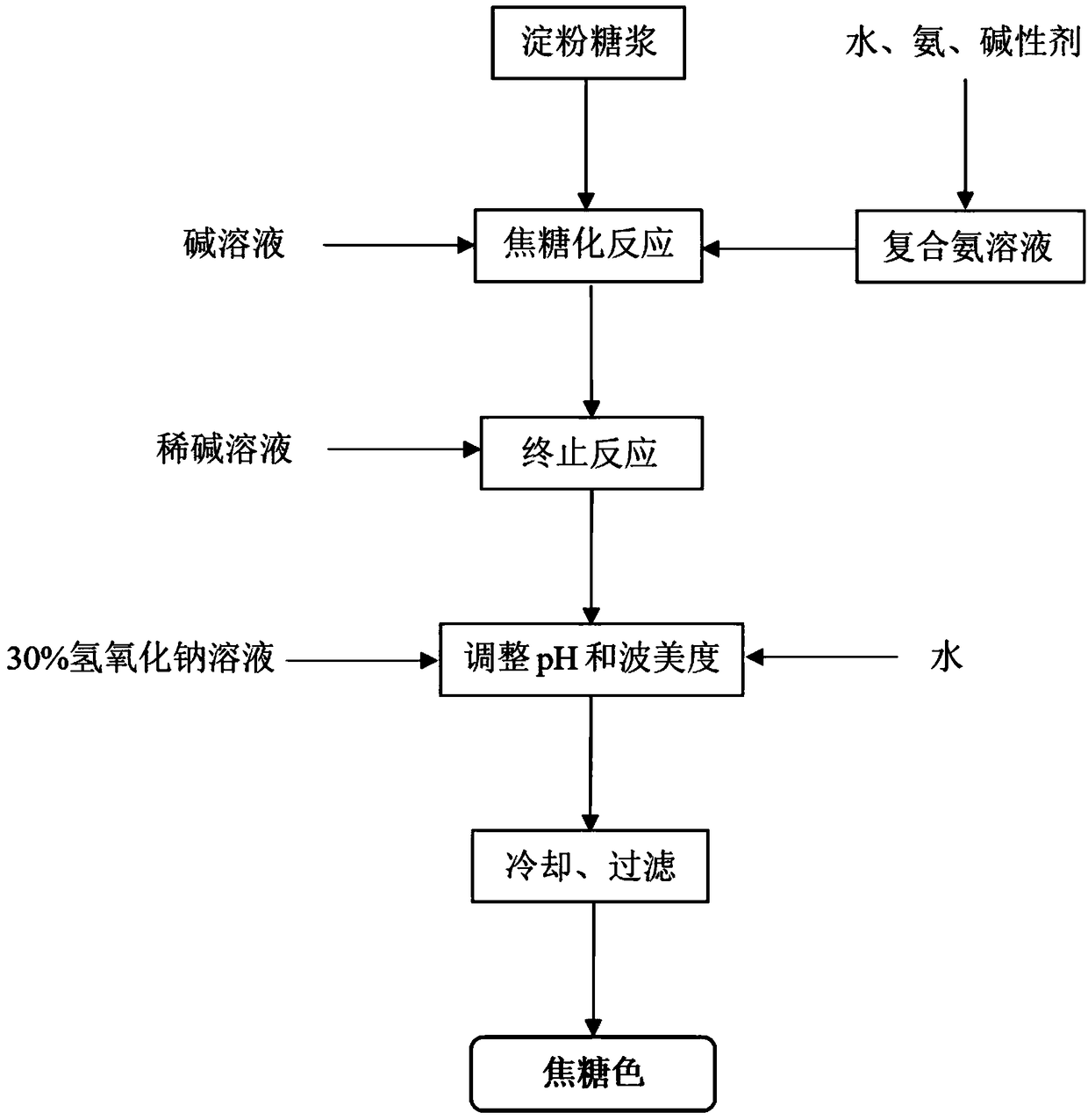

[0043] A kind of production method of caramel color (process flow chart is as figure 1 shown), the steps are as follows:

[0044] 1) Prepare starch syrup with a dry matter content of 81.0% and a pH of 5.03, and perform desalting and refining;

[0045] 2) 1420kg of deionized water, 200kg of liquid ammonia and 41.3kg of sodium hydroxide were fully stirred evenly to obtain a compound ammonia solution;

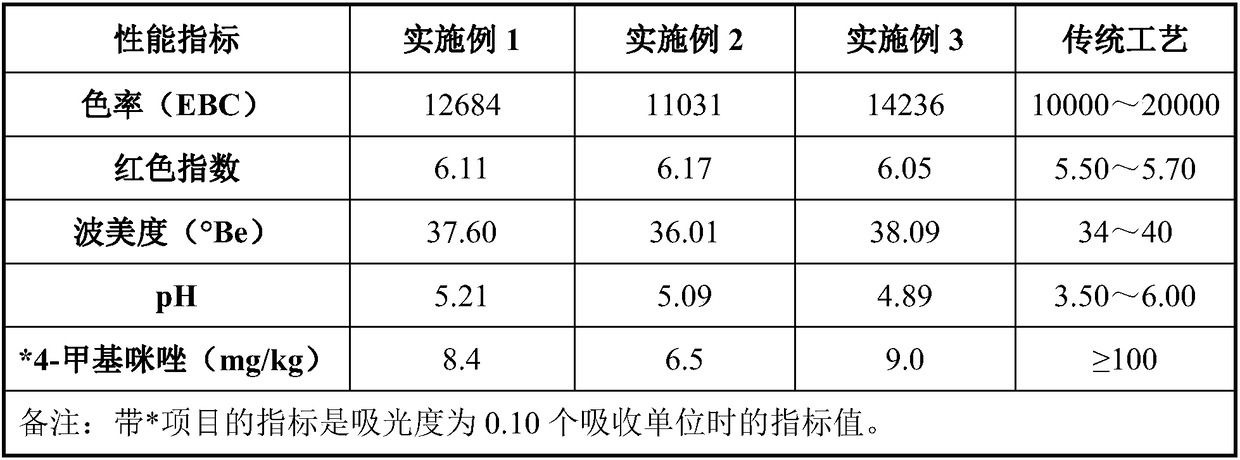

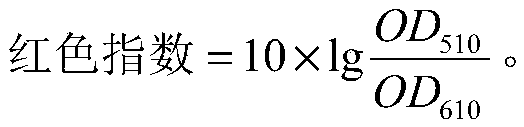

[0046] 3) Put 8500kg of starch syrup into the reaction kettle, then control the pressure inside the kettle at -0.01~-0.001MPa, control the temperature at 110±2°C, add 30kg of 30% sodium hydroxide solution, stir and mix for 20min, and then put The compound ammonia solution is added into the reaction kettle at a speed of 1.5±0.5kg compound ammonia solution / 1000kg starch syrup / min, stop adding when the color rate of the material in the kettle is 6000~11000EBC, and continue the reaction, when the color rate of the material in the kettle is Add 860kg of 3.54% sodium hydroxide solutio...

Embodiment 2

[0049] A kind of production method of caramel color (process flow chart is as figure 1 shown), the steps are as follows:

[0050] 1) Prepare starch syrup with a dry matter content of 80.8% and a pH of 5.05, and perform desalting and refining;

[0051] 2) fully stir 1480kg deionized water, 560kg ammonia water (ammonia content is 27.8%) and 40.8kg sodium bicarbonate to obtain a compound ammonia solution;

[0052]3) Add 8500kg of starch syrup into the reaction kettle, then control the pressure inside the kettle at -0.01~-0.001MPa, control the temperature at 110±2°C, add 32kg of 30% sodium hydroxide solution, stir and mix for 25min, and then put The compound ammonia solution is added into the reaction kettle at a rate of 1.2±0.5kg compound ammonia solution / 1000kg starch syrup / min, stop adding when the color rate of the material in the kettle is 6000~11000EBC, and continue the reaction, when the color rate of the material in the kettle is Add 790kg of sodium hydroxide solution wi...

Embodiment 3

[0055] A kind of production method of caramel color (process flow chart is as figure 1 shown), the steps are as follows:

[0056] 1) Prepare starch syrup with a dry matter content of 78.8% and a pH of 4.68, and perform desalting and refining;

[0057] 2) 1260kg of deionized water, 805kg of ammonia water (the ammonia content is 27.5%) and 15kg of potassium hydroxide are fully stirred evenly to obtain a compound ammonia solution;

[0058] 3) Put 8800kg of starch syrup into the reaction kettle, then control the pressure inside the kettle at -0.01~-0.001MPa, control the temperature at 110±2°C, add 57kg of 30% sodium hydroxide solution, stir and mix for 20min, and then put Add the compound ammonia solution into the reaction kettle at a rate of 1.3±0.5kg compound ammonia solution / 1000kg starch syrup / min, stop adding when the color rate of the material in the kettle is 6000-11000EBC, and continue the reaction, when the color rate of the material in the kettle is Add 980kg of sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com