A kind of production method of caramel color

A production method, caramel color technology, applied in chemical instruments and methods, functions of food ingredients, organic dyes, etc., to achieve the effects of reducing the generation of harmful by-products, good quality, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

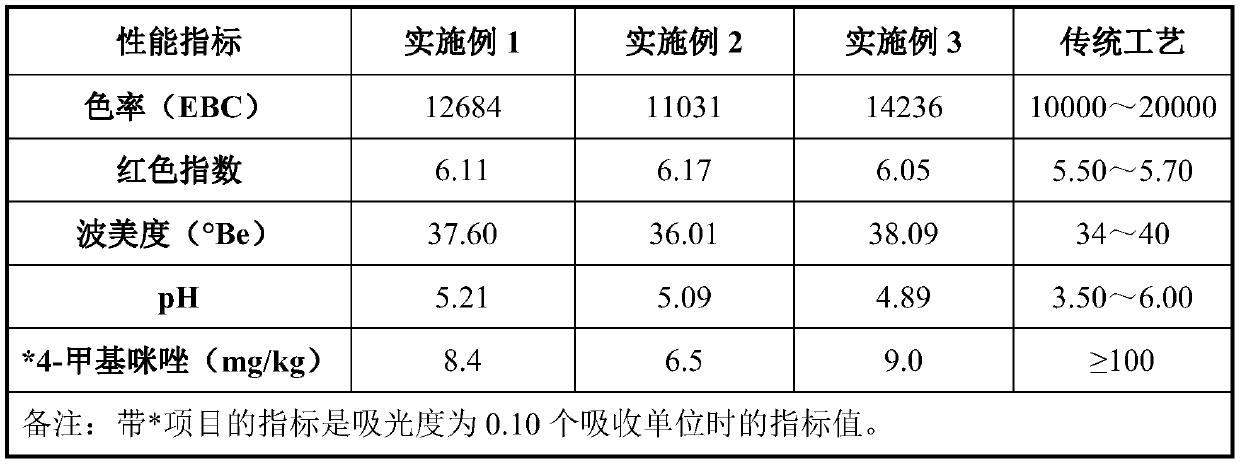

Embodiment 1

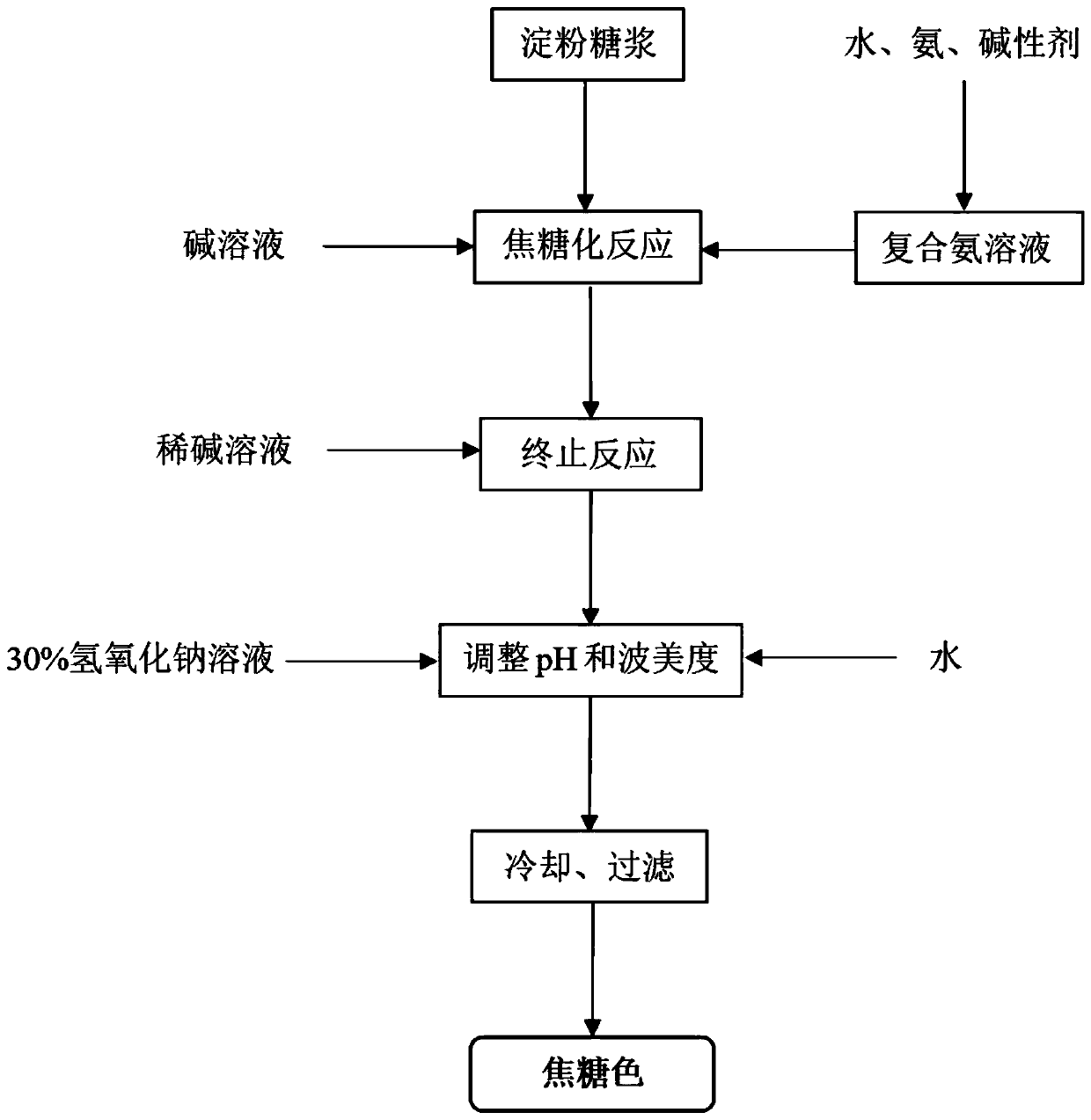

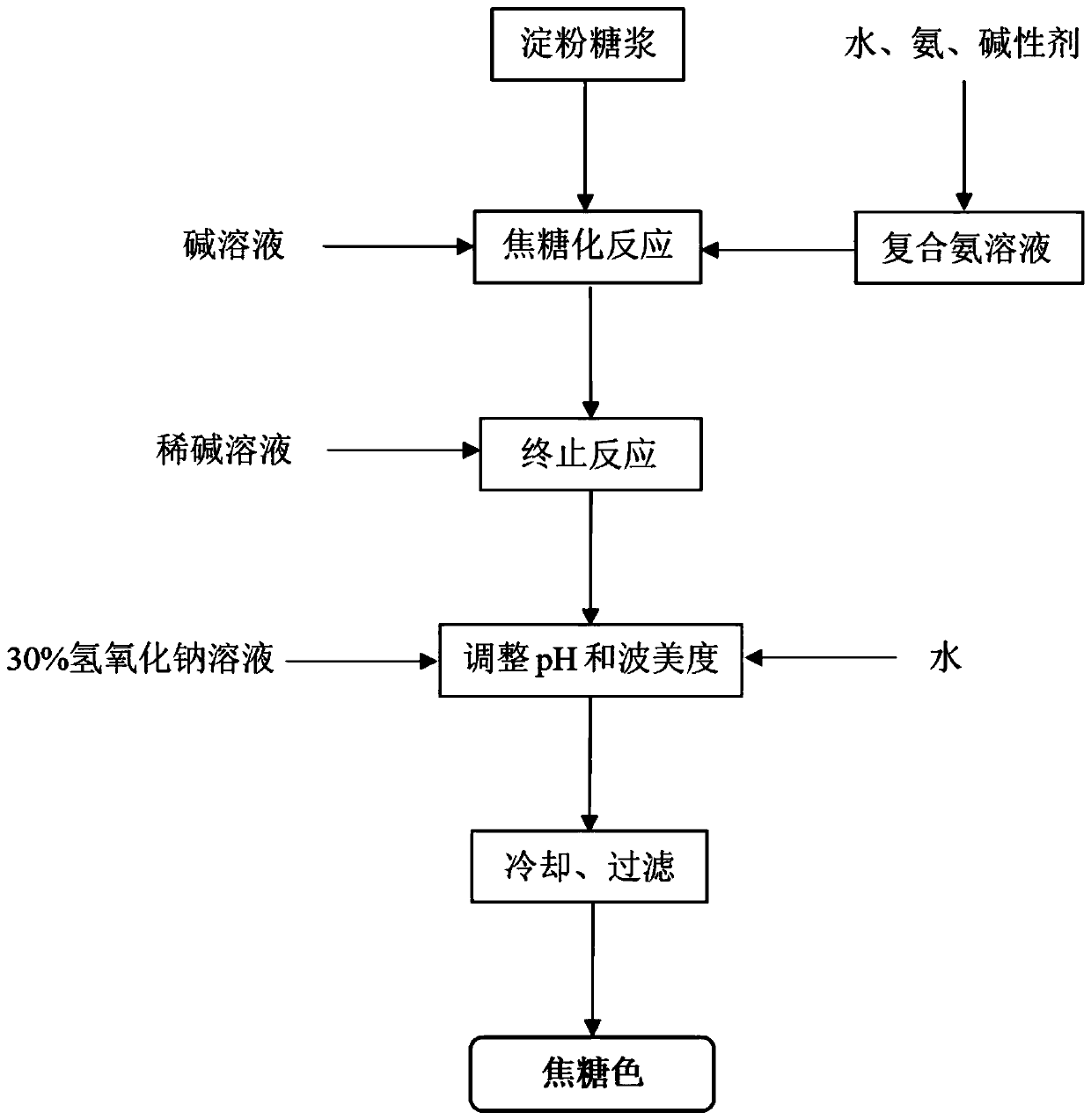

[0043] A kind of production method of caramel color (process flow chart is as figure 1 shown), the steps are as follows:

[0044] 1) Prepare starch syrup with a dry matter content of 81.0% and a pH of 5.03, and perform desalting and refining;

[0045] 2) 1420kg of deionized water, 200kg of liquid ammonia and 41.3kg of sodium hydroxide were fully stirred evenly to obtain a compound ammonia solution;

[0046] 3) Put 8500kg of starch syrup into the reaction kettle, then control the pressure inside the kettle at -0.01~-0.001MPa, control the temperature at 110±2°C, add 30kg of 30% sodium hydroxide solution, stir and mix for 20min, and then put The compound ammonia solution is added into the reaction kettle at a speed of 1.5±0.5kg compound ammonia solution / 1000kg starch syrup / min, stop adding when the color rate of the material in the kettle is 6000~11000EBC, and continue the reaction, when the color rate of the material in the kettle is Add 860kg of 3.54% sodium hydroxide solutio...

Embodiment 2

[0049] A kind of production method of caramel color (process flow chart is as figure 1 shown), the steps are as follows:

[0050] 1) Prepare starch syrup with a dry matter content of 80.8% and a pH of 5.05, and perform desalting and refining;

[0051] 2) fully stir 1480kg deionized water, 560kg ammonia water (ammonia content is 27.8%) and 40.8kg sodium bicarbonate to obtain a compound ammonia solution;

[0052]3) Add 8500kg of starch syrup into the reaction kettle, then control the pressure inside the kettle at -0.01~-0.001MPa, control the temperature at 110±2°C, add 32kg of 30% sodium hydroxide solution, stir and mix for 25min, and then put The compound ammonia solution is added into the reaction kettle at a rate of 1.2±0.5kg compound ammonia solution / 1000kg starch syrup / min, stop adding when the color rate of the material in the kettle is 6000~11000EBC, and continue the reaction, when the color rate of the material in the kettle is Add 790kg of sodium hydroxide solution wi...

Embodiment 3

[0055] A kind of production method of caramel color (process flow chart is as figure 1 shown), the steps are as follows:

[0056] 1) Prepare starch syrup with a dry matter content of 78.8% and a pH of 4.68, and perform desalting and refining;

[0057] 2) 1260kg of deionized water, 805kg of ammonia water (the ammonia content is 27.5%) and 15kg of potassium hydroxide are fully stirred evenly to obtain a compound ammonia solution;

[0058] 3) Put 8800kg of starch syrup into the reaction kettle, then control the pressure inside the kettle at -0.01~-0.001MPa, control the temperature at 110±2°C, add 57kg of 30% sodium hydroxide solution, stir and mix for 20min, and then put Add the compound ammonia solution into the reaction kettle at a rate of 1.3±0.5kg compound ammonia solution / 1000kg starch syrup / min, stop adding when the color rate of the material in the kettle is 6000-11000EBC, and continue the reaction, when the color rate of the material in the kettle is Add 980kg of 3.64% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com