Lightfast mildew-resistant red pigment

A red pigment and anti-mildew technology, applied in the field of red pigments, can solve the problems that red pigments cannot be stored for a long time, prolong the storage time of paintings, and lose the preservation value of paintings, so as to improve the combination fastness and light resistance, maintain bright colors, The effect of prolonging the preservation value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

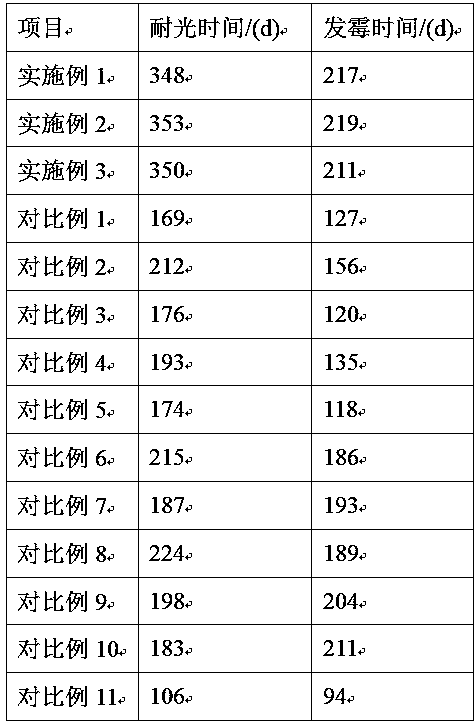

Examples

Embodiment 1

[0021] A light-resistant and mildew-resistant red pigment is prepared from the following raw materials in parts by weight: ferric thiocyanate 17, zeolite powder 11, hydroxyethyl cellulose 7, nano-titanium oxide 6, fumed silica 6, sulfamic acid 3 , silicone oil 1.4, water 5.

[0022] The zeolite powder has a particle size of 80-100 nm.

[0023] The nanometer titanium oxide has a particle size of 30-40 nm.

[0024] A preparation method of a light-resistant and mildew-resistant red pigment, comprising the following steps:

[0025] (1) Place the zeolite powder in the reactor, heat it to 340°C, the heating rate is 1°C / min, and keep the temperature for 4 hours to heat the zeolite powder;

[0026] (2) adding ferric thiocyanate into distilled water, mixing evenly, so that the concentration of ferric thiocyanate solution is 140mg / L, to obtain ferric thiocyanate solution;

[0027] (3) until the temperature of the heated zeolite powder in step (1) is lowered to 170°C, add ferric thioc...

Embodiment 2

[0034] A light-resistant and mildew-resistant red pigment is prepared from the following raw materials in parts by weight: ferric thiocyanate 18, zeolite powder 12, hydroxyethyl cellulose 8, nano-titanium oxide 7, fumed silica 7, sulfamic acid 4 , silicone oil 1.5, water 6.

[0035] The zeolite powder has a particle size of 80-100 nm.

[0036] The nanometer titanium oxide has a particle size of 30-40 nm.

[0037] A preparation method of a light-resistant and mildew-resistant red pigment, comprising the following steps:

[0038] (1) Place the zeolite powder in the reactor, heat it to 370°C, the heating rate is 1.5°C / min, and keep the temperature for 4.5 hours to heat the zeolite powder;

[0039] (2) adding ferric thiocyanate into distilled water, mixing evenly, so that the concentration of ferric thiocyanate solution is 150mg / L, to obtain ferric thiocyanate solution;

[0040] (3) until the temperature of the heated zeolite powder in step (1) drops to 180°C, add ferric thiocy...

Embodiment 3

[0047] A light-resistant and mildew-resistant red pigment is prepared from the following raw materials in parts by weight: ferric thiocyanate 19, zeolite powder 13, hydroxyethyl cellulose 9, nano-titanium oxide 8, fumed silica 8, sulfamic acid 5 , silicone oil 1.6, water 7.

[0048] The zeolite powder has a particle size of 80-100 nm.

[0049] The nanometer titanium oxide has a particle size of 30-40 nm.

[0050] A preparation method of a light-resistant and mildew-resistant red pigment, comprising the following steps:

[0051] (1) Place the zeolite powder in the reactor, heat it to 400°C, the heating rate is 2°C / min, and keep the temperature for 5 hours to heat the zeolite powder;

[0052](2) adding ferric thiocyanate into distilled water, mixing evenly, so that the concentration of ferric thiocyanate solution is 160 mg / L, to obtain ferric thiocyanate solution;

[0053] (3) until the temperature of the heated zeolite powder in step (1) is lowered to 190°C, add ferric thioc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com