IDT copper process manufacturing method for high-frequency surface acoustic wave (SAW)

A manufacturing method and process technology, which is applied in the field of surface acoustic wave filter manufacturing, can solve problems such as the inability to complete the exposure and stripping process, limit the application of SAW products, and difficult to control the electrode shape, and achieve easy to achieve, performance improvement, and small insertion The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

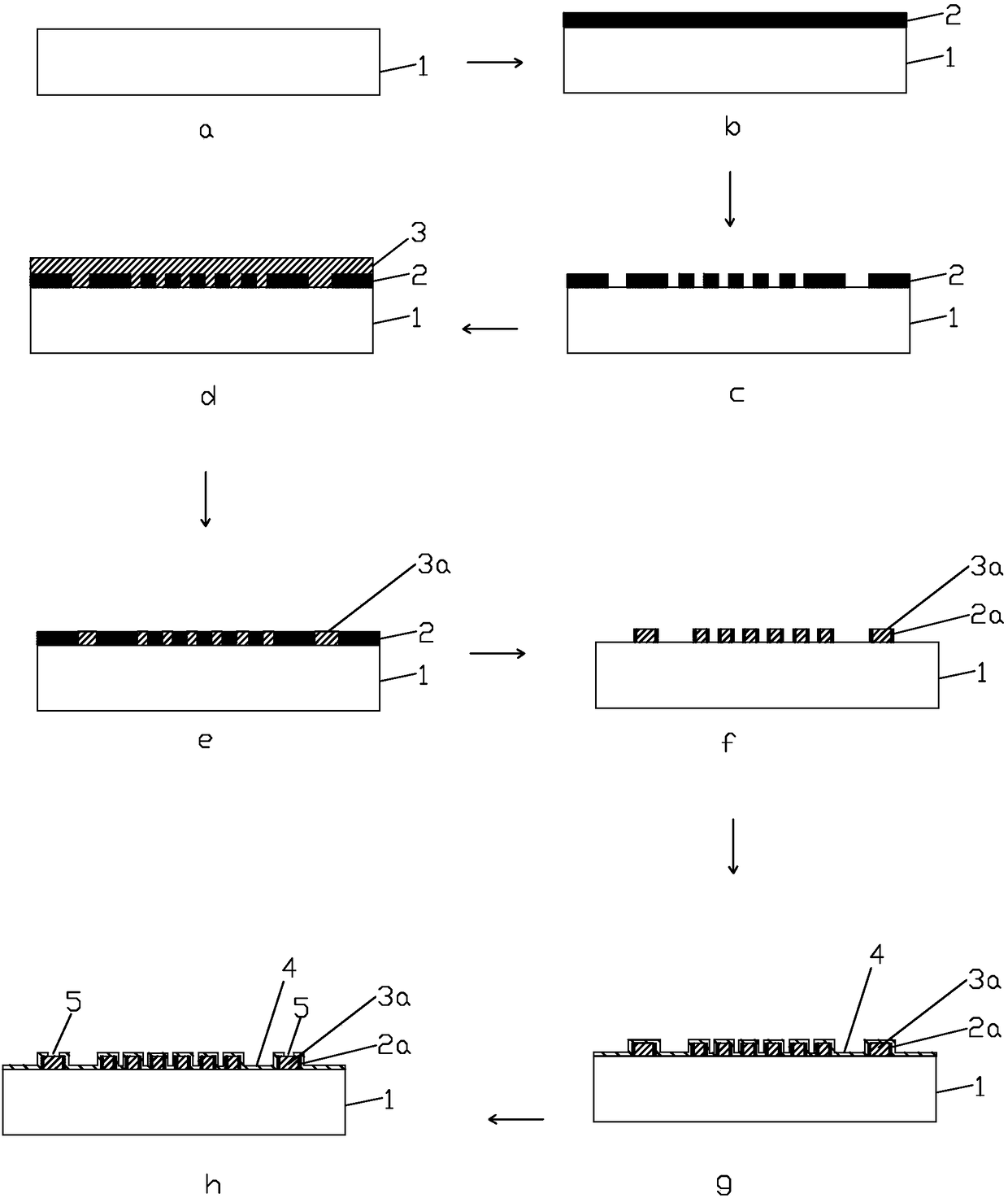

[0028] Combine the following figure 1 The process flow diagram of the IDT copper process manufacturing method of the high frequency SAW of the present invention is shown to illustrate the present invention in detail.

[0029] Referring to 1a, a piezoelectric material substrate 1 is provided, which may be, for example, a lithium tantalate or a lithium tantalate-on-silicon crystal or the like.

[0030] refer to figure 1 b, depositing a dielectric material on the substrate 1 to form a first dielectric layer 2 . Dielectric materials include SiO 2 , Si 3 N 4 , Si x N y etc., deposited by methods such as CVD / PVD. The thickness of the first dielectric layer 2 ranges from 100 to 500 nm, for example, the reference is 300 nm. The thickness of the first dielectric layer 2 defines the thickness of the IDT metal, which can be adjusted according to product design requirements.

[0031] refer to figure 1 c. Coat positive photoresist, define the IDT pattern after exposure and develo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com