Multifunctional composite catalyst as well as preparation method and application thereof

A composite catalyst and multi-functional technology, applied in molecular sieve catalysts, chemical instruments and methods, preparation of liquid hydrocarbon mixtures, etc., to achieve good application prospects, prevent carbon deposition, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

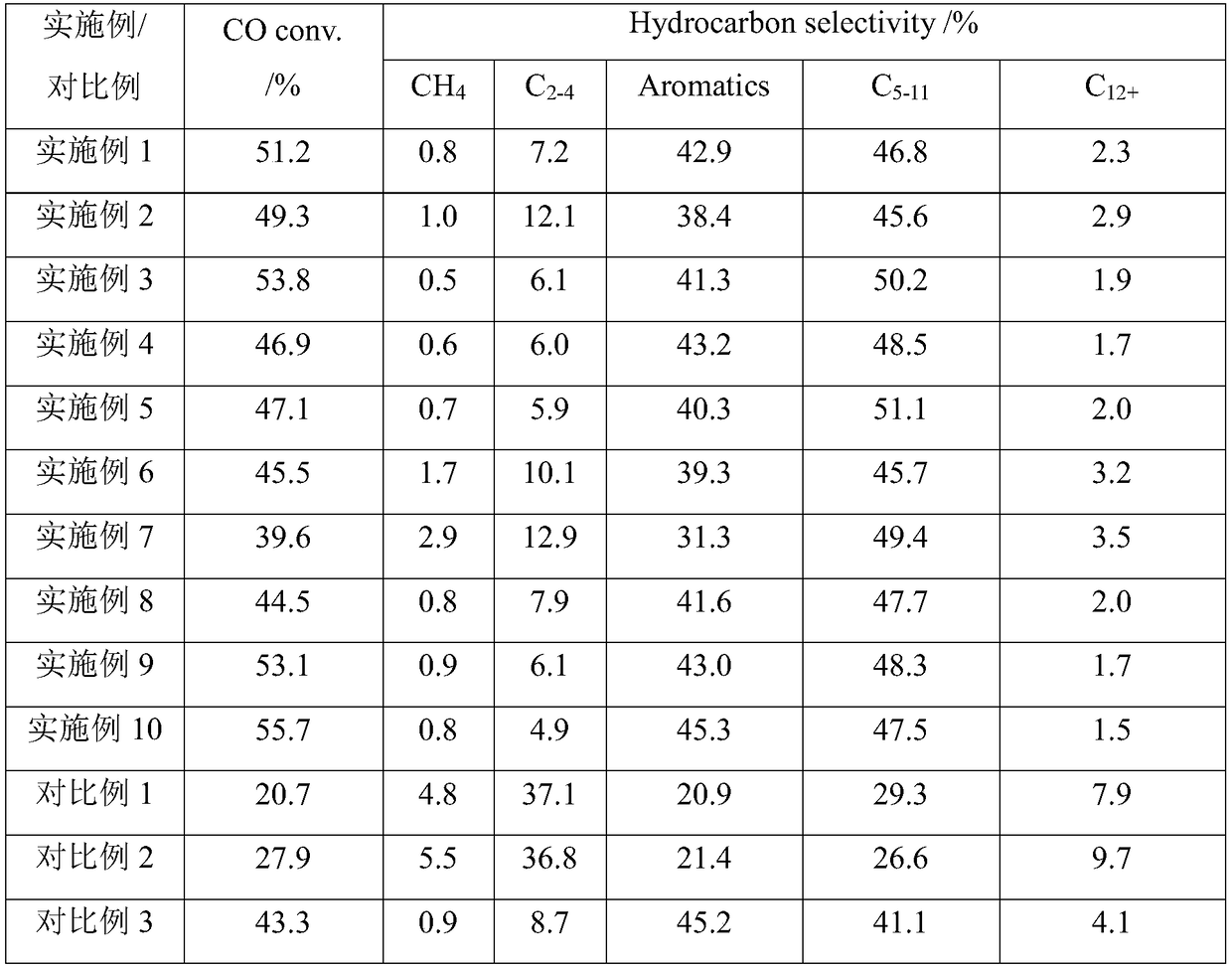

Examples

Embodiment 1

[0033] Weigh 0.54g Mo(CH 3 COO) 2 , add 50ml of deionized water, stir at 60°C for 1h to form a solution, then add 3.75g of Zn(NO 3 ) 2 ·6H 2O was added to the above solution, stirred at 60 °C for 1 h, then 2.4 g of carbon nanotubes were added, and stirred at 70 °C for 10 h. The obtained solid-liquid mixture sample was moved to a vacuum drying oven and dried at 100°C for 10 hours. After the dried solid was ground, it was moved to a muffle furnace and heated at a rate of 2°C / min to 500°C for 10 hours. The calcined samples were placed in a tube furnace, fed with hydrogen gas at a rate of 2 °C / min to 300 °C for reduction, and the reduction time was 10 h. The resulting product is ZnO-MoO 3 (1 / 0.1).

[0034] Weigh 0.029g Ga(NO 3 ) 3 4.5H 2 O was added into 50ml of deionized water to form a solution, then 3g of H-ZSM-5 molecular sieve was added, and then the above solution was stirred at 40-90°C for 1-10 hours, and the obtained solid-liquid mixture was transferred to a vacuu...

Embodiment 2

[0038] Weigh 0.54g Mo(CH 3 COO) 2 , add 50ml of deionized water, stir at 60°C for 1h to form a solution, then add 1.45g of MnCO 3 Added to the above solution, stirred at 60°C for 1h, then added 2.4g of activated carbon, stirred at 70°C for 10h. The obtained solid-liquid mixture sample was moved to a vacuum drying oven and dried at 100°C for 10 hours. After the dried solid was ground, it was moved to a muffle furnace and heated at a rate of 2°C / min to 500°C for 10 hours. The calcined samples were placed in a tube furnace, fed with hydrogen gas at a rate of 2 °C / min to 350 °C for reduction, and the reduction time was 10 h. The resulting product is MnO 2 -MoO 3 (1 / 0.1).

[0039] Weigh 0.015g CaCO 3 Add 50ml of deionized water to make a solution, then add 3g of H-ZSM-5 molecular sieve, then continue to stir the above solution at 40-90°C for 1-10h, and move the obtained solid-liquid mixture into a vacuum drying oven at 60-120°C Drying, the time is 1-24h, the dried sample is ...

Embodiment 3

[0043] Weigh 0.54g Mo(CH 3 COO) 2 , add 50ml deionized water, stir at 60°C for 1h to form a solution, then add 2.47g Cr 2 (SO 4 ) 3 ·6H 2 O was added to the above solution, stirred at 60°C for 1h, then 2.4g of carbon black was added, and stirred at 70°C for 10h. The obtained solid-liquid mixture sample was moved to a vacuum drying oven and dried at 100°C for 10 hours. After the dried solid was ground, it was moved to a muffle furnace and heated at a rate of 2°C / min to 500°C for 10 hours. The calcined samples were placed in a tube furnace, fed with hydrogen gas at a rate of 2 °C / min to 350 °C for reduction, and the reduction time was 10 h. The resulting product is CrO 3 -MoO 3 (1 / 0.1).

[0044] Weigh 0.027g Zn(NO 3 ) 2 ·6H 2 O was added into 50ml of deionized water to form a solution, then 3g of H-ZSM-5 molecular sieve was added, and then the above solution was stirred at 40-90°C for 1-10 hours, and the obtained solid-liquid mixture was transferred to a vacuum drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com