Image sensor and method for forming same

An image sensor and graphics technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of small size, and achieve the effect of reduced usage, good controllability, and guaranteed performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the existing manufacturing process of the image sensor, in order to reduce the optical crosstalk of the incident light received by the image sensor device, it is necessary to form a metal grid on the surface of the semiconductor substrate.

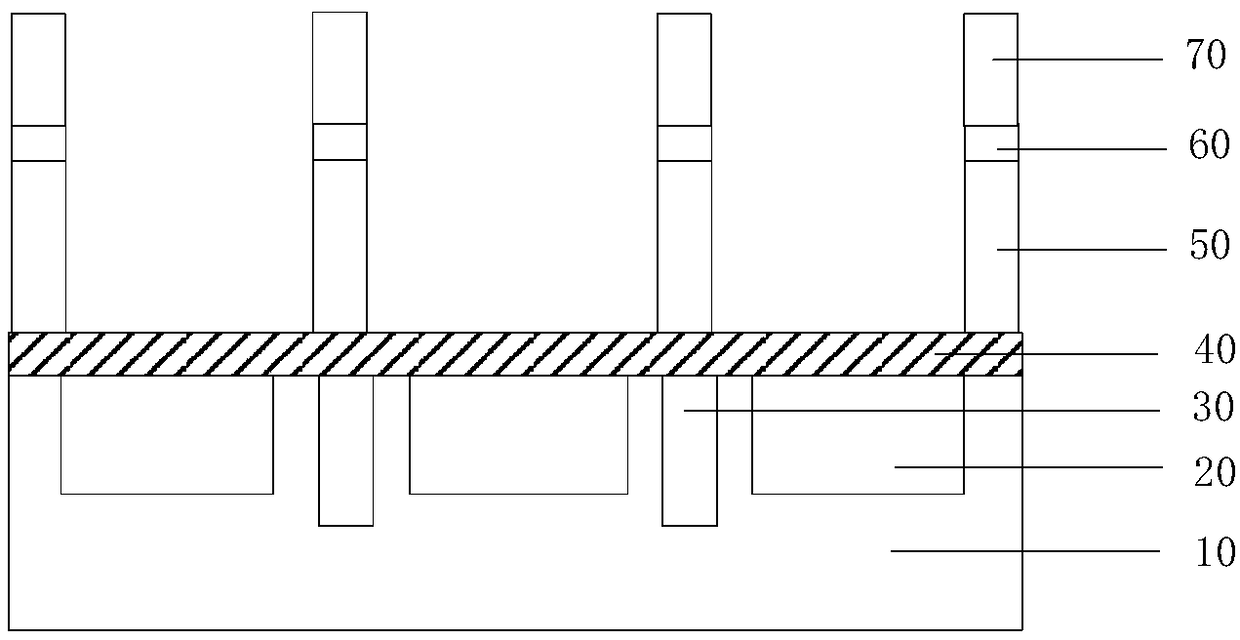

[0025] Specifically, you can refer to figure 1 An image sensor formed by a prior art process is shown.

[0026] refer to figure 1 , a semiconductor substrate 10 is provided, and discrete photodiodes 20 are formed in the semiconductor substrate, and the discrete photodiodes 20 are isolated by deep trench isolation structures 30, and the deep trench isolation structures 30 The depth of the photodiode 20 is deeper than that of the photodiode 20, so as to obtain a better isolation effect and avoid the problem of diffusion of photo-generated carriers between different pixel regions.

[0027] Then continue to refer to figure 1 , forming an interlayer dielectric layer 40 made of silicon oxide or silicon nitride or a combination of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com