High temperature carbide slag cooling quenching granulation method and production device

A technology of high-temperature carbonization and slag cooling, applied in the direction of granulating raw materials, chemical instruments and methods, titanium halide, etc., can solve problems such as increased investment, and achieve energy saving, small performance changes, and environmentally friendly production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

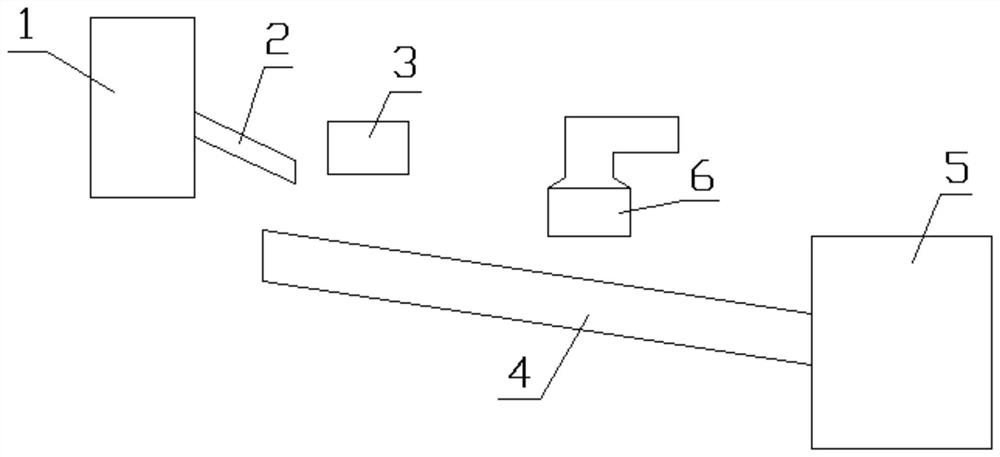

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] The method for cooling and quenching granulation of high-temperature carbide slag comprises the following steps:

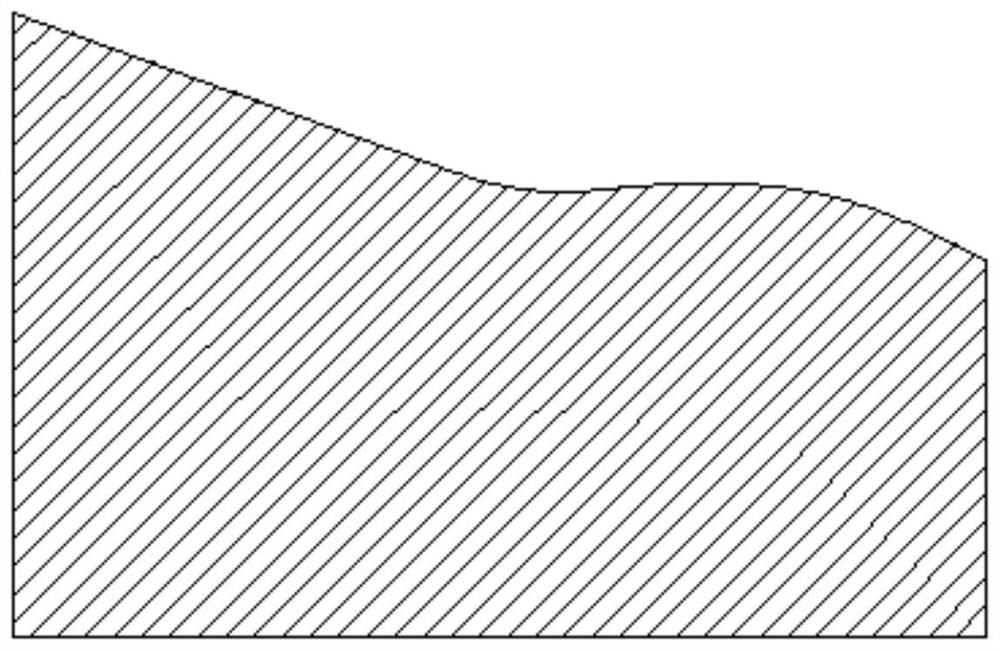

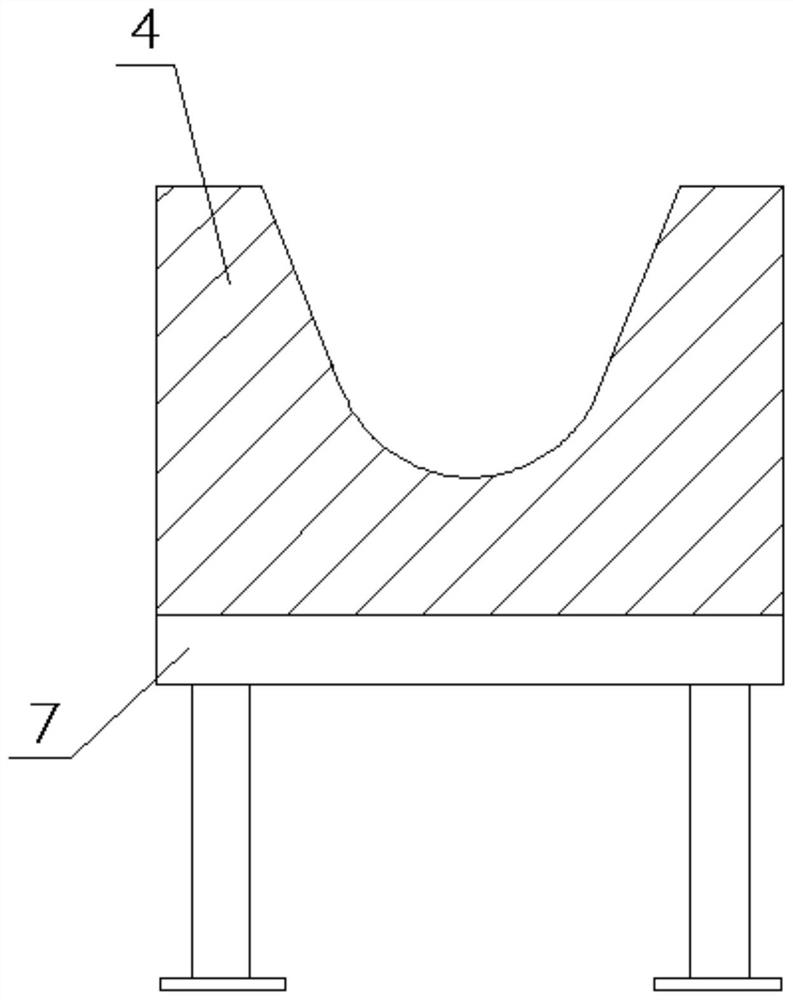

[0028] Step 1: The carbide slag with a temperature of >1700°C is discharged from the carbonization furnace, and after passing through the slag ditch, the carbide slag can enter the water slag ditch in a parabolic form at a temperature point of >1650°C. The preferred implementation of the slag ditch is as follows: the length of the slag ditch is ≤1.5m and the slope is >20°. 50°C, its cross-sectional structure is as figure 2 shown. In the present invention, by designing a reasonable form of the slag ditch, the high-temperature slag can enter the punching point at a reasonable angle, timing and time, and can fully and quickly contact with the punching water to realize self-granulation.

[0029] Step 2: Transport the brewing water to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com