Biomass carbon-based solid acid catalyst and preparation method and application thereof

A carbon-based solid acid and biomass technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic chemistry, etc., can solve the problems of general cycle effect, low yield of glucose conversion to HMF, etc., and achieve catalytic conversion efficiency High, high catalytic activity, the effect of increasing the loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing a biomass carbon-based solid acid catalyst, comprising:

[0025] A) immersing the biomass of nitrogen-containing compounds in an acid solution, and filtering to obtain a solid product;

[0026] B) carbonizing the solid product to obtain a porous carbon carrier;

[0027] C) reacting the porous carbon carrier with p-aminobenzenesulfonic acid and isoamyl nitrite to obtain a catalyst through sulfonation.

[0028] In the present invention, firstly, the biomass containing nitrogen compounds is soaked in an acid solution.

[0029] The nitrogen-containing compound biomass of the present invention includes but not limited to tobacco stems or bean straws; the embodiment of the present invention uses tobacco stems.

[0030] In the present invention, it is preferred to firstly dry and grind the biomass containing nitrogen compounds at 100-105°C. The present invention does not limit the specific manner of grinding, as long as those sk...

Embodiment 1-4

[0071] Embodiment 1-4. the preparation of catalyst A-D

[0072] Take 10 g of ground tobacco stem powder as a raw biomass material rich in nitrogen-containing compounds, soak it in 45% pyrophosphoric acid solution for 12 hours, the mass ratio of pyrophosphoric acid and tobacco stem is 1.3:1, and then filter the filtrate; Under the protection of an inert gas, carbonize the obtained solid at 350, 400, 450, and 500°C for 1 hour to obtain a black solid. 1~4. In the sulfonation process, a certain amount of porous carbon is first impregnated in water and stirred, then sequentially added p-aminobenzenesulfonic acid and isoamyl nitrite (mass: 2:1) and refluxed at 80°C for 12 hours. After the end, the solid-liquid separation and Washed and dried under vacuum at 80°C for 12 hours to obtain the corresponding catalysts numbered sequentially A-D.

Embodiment 5-8

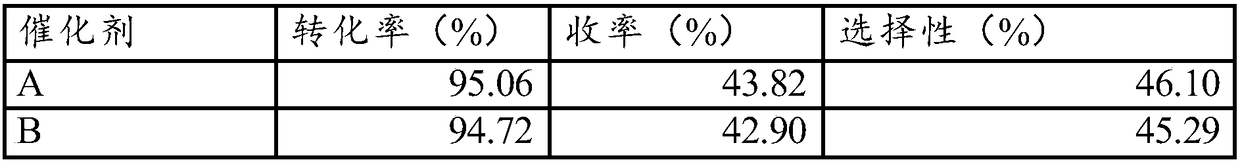

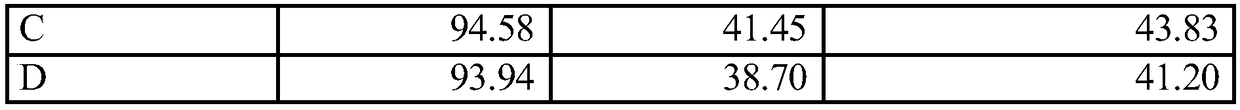

[0074] Add 0.1g of fructose, 4.7ml of γ-valerolactone, 0.3ml of water, and 0.05g of catalyst into a 15ml pressure-resistant tube, and react for 30min at a speed of 500r / min at a temperature of 130°C. After completion, filter the reaction solution and use HPLC detection of sugar and HMF products. The specific results are shown in Table 1.

[0075] Table 1. The conversion rate of fructose under different catalysis, the yield and selectivity of HMF

[0076] catalyst

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com