Silver chromate/sulfur-doped carbon nitride Z-type photocatalyst and preparation method thereof

A technology of photocatalyst and carbon nitride, which is applied in the field of photocatalysis, can solve problems such as the inability to effectively improve the structural and optical properties of carbon nitride, the cumbersome and complicated synthesis process of sulfur-doped carbon nitride, and the limitations of the practical application of photocatalysts. The photogenerated electron-hole recombination rate is low, the cost is low, and the conditions are easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

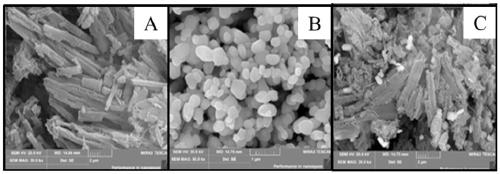

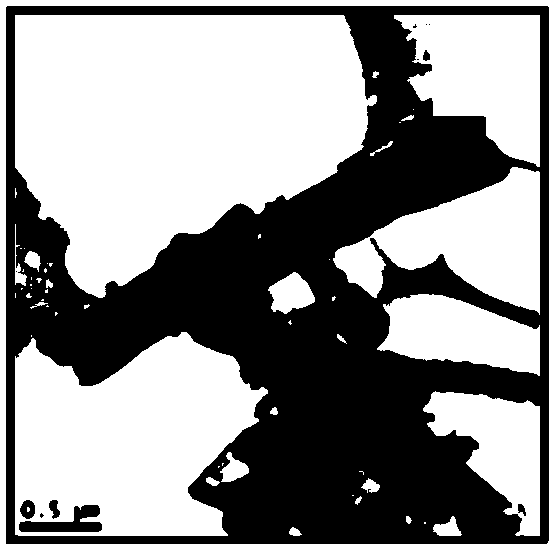

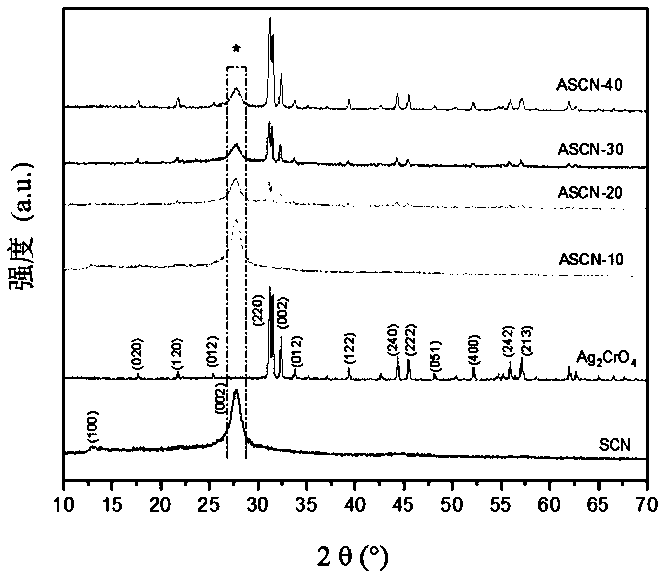

[0042] A silver chromate / sulfur-doped carbon nitride Z-type photocatalyst comprises carbon nitride, the carbon nitride is doped with sulfur elements to form sulfur-doped carbon nitride, and the surface of the sulfur-doped carbon nitride is modified with silver chromate. That is, the silver chromate / sulfur-doped carbon nitride Z-type photocatalyst of the present invention uses carbon nitride as a carrier, and the carbon nitride is doped with sulfur element and its surface is modified with silver chromate.

[0043] In this embodiment, the mass percentage of sulfur-doped carbon nitride in the silver chromate / sulfur-doped carbon nitride Z-shaped rod-shaped photocatalyst is 70%, and the mass percentage of silver chromate is 30%.

[0044] In this embodiment, silver chromate is in granular form; sulfur-doped carbon nitride is in rod form.

[0045] A preparation method of the silver chromate / sulfur-doped carbon nitride Z-type photocatalyst of the above-mentioned present embodiment, co...

Embodiment 2

[0053] A silver chromate / sulfur-doped carbon nitride Z-type photocatalyst is basically the same as the silver chromate / sulfur-doped carbon nitride Z-type photocatalyst of embodiment 1, the difference is only: the silver chromate / sulfur of embodiment 2 The mass percent content of silver chromate in the carbon nitride-doped Z-type photocatalyst is 10%.

[0054] A preparation method of silver chromate / sulfur-doped carbon nitride Z-type photocatalyst in the above-mentioned present embodiment is basically the same as the preparation method of embodiment 1, the only difference is that the amount of silver nitrate solution in embodiment 2 is 0.9 mL , and the amount of potassium dichromate solution is 0.5mL.

[0055] The silver chromate / sulfur-doped carbon nitride Z-type photocatalyst prepared in Example 2 is designated as ASCN-10.

Embodiment 3

[0057] A silver chromate / sulfur-doped carbon nitride Z-type photocatalyst is basically the same as the silver chromate / sulfur-doped carbon nitride Z-type photocatalyst of embodiment 1, the difference is only: the silver chromate / sulfur of embodiment 3 The mass percent content of silver chromate in the carbon nitride-doped Z-type photocatalyst is 20%.

[0058] A preparation method of silver chromate / sulfur-doped carbon nitride Z-type photocatalyst in the above-mentioned present embodiment is basically the same as the preparation method of embodiment 1, the only difference is that the amount of silver nitrate solution in embodiment 3 is 1.8 mL , and the amount of potassium dichromate solution is 1.0mL.

[0059] The silver chromate / sulfur-doped carbon nitride Z-type photocatalyst prepared in Example 3 is designated as ASCN-20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com