High-light-absorption high-heat-conductivity fatty acid/nano complex modified vermiculite composite phase-change energy storage material and preparation method thereof

A nano-composite and composite phase change technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of low latent heat of phase change, low thermal conductivity, poor light-to-heat conversion ability, etc., and achieve high thermal conductivity and The effect of phase change enthalpy, increasing specific surface area, and improving pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Weigh 15g of myristic acid and place it in a beaker, then put it into a constant temperature water bath at 90°C, heat and stir for 10 minutes, ultrasonicate for 3 minutes, take it out and cool to room temperature; the melting point of myristic acid is 54.6°C determined by differential scanning calorimetry , the freezing point is 51.8°C, and the latent heat of phase change is 189.4J / g.

[0035] (2) After making a solution of 3g of sucrose, 15mL of water and 1mL of glacial acetic acid, add 5g of expanded vermiculite, stir at room temperature for 20min, then ultrasonicate for 3min to form a uniformly dispersed solution system, and then add 1.5mL of orthosilicate The mixed solution of ethyl ester and 1.5mL absolute ethanol, after the dropwise addition, the temperature was raised to 60°C and continued to stir for 2h, then the solution was poured into a hydrothermal kettle, reacted at 180°C for 12h, then placed in a 70°C oven to dry and After grinding, the obtained precur...

Embodiment 2

[0038] (1) Mix lauric acid, myristic acid, and stearic acid evenly in a mass ratio of 60.7: 29.9: 9.4, heat and stir in a constant temperature water bath at 80°C for 20 minutes, take it out and cool to room temperature after ultrasonication for 2 minutes; The melting point of the lauric acid / myristic acid / stearic acid ternary eutectic mixture determined by thermal method is 31.0°C, the freezing point is 27.6°C, and the latent heat of phase transition is 164.0J / g.

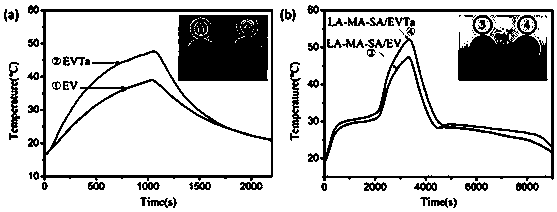

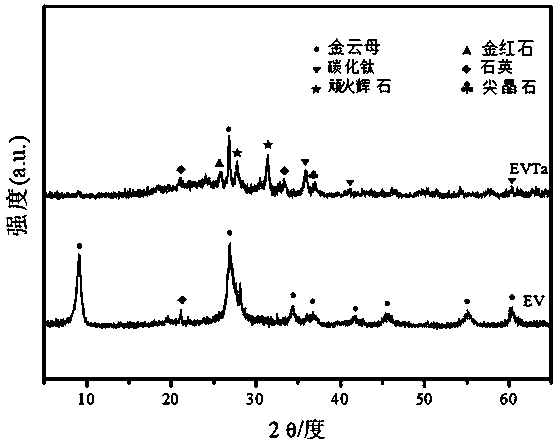

[0039] (2) Measure 1.42mL of tetrabutyl titanate, add 12.78mL of absolute ethanol, stir magnetically for 15min, add 0.48mL of glacial acetic acid, stir vigorously for 15min, then add 5g of expanded vermiculite (EV), stir for 1h, and ultrasonically After shaking for 30 minutes, continue to stir, then add dropwise a mixture of 3mL absolute ethanol and 0.3mL distilled water at a rate of about 1 drop / 5s, adjust the pH of the solution to about 1~2 with 0.01mL nitric acid, and stir vigorously at room temperature for 2 hour...

Embodiment 3

[0043] (1) Mix lauric acid, myristic acid, and stearic acid evenly in a mass ratio of 60.7: 29.9: 9.4, heat and stir in a constant temperature water bath at 80°C for 30 minutes, take it out and cool to room temperature after ultrasonication for 2 minutes; The melting point of the lauric acid / myristic acid / stearic acid ternary eutectic mixture determined by thermal method is 31.0°C, the freezing point is 27.6°C, and the latent heat of phase transition is 164.0J / g.

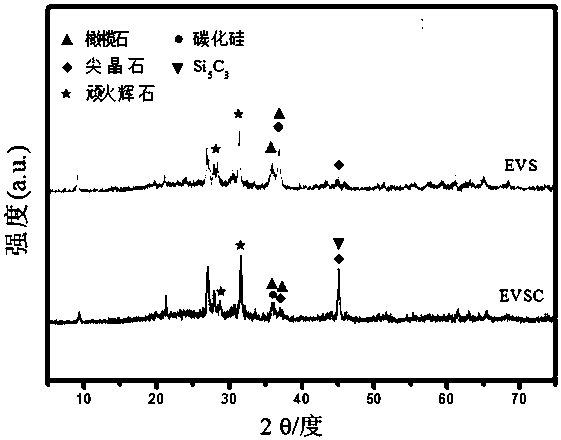

[0044] (2) After making a solution of 3g of sucrose, 15mL of water and 1mL of ammonia water, add 5g of expanded vermiculite, stir at room temperature for 20min, then sonicate for 3min to form a uniformly dispersed solution system, and then add 1.5mL of tetraethyl orthosilicate dropwise Mixed solution of ester and 1.5mL of absolute ethanol, after the dropwise addition, raise the temperature to 60°C and continue to stir for 2h, then pour the solution into a hydrothermal kettle, react at 180°C for 11h, then dry and grin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com