Black iron oxide pigment and preparation method thereof

A technology of iron oxide black and pigments, applied in the field of pigments, can solve the problems of poor temperature resistance, easy agglomeration, and limited application range of iron oxide black, and achieve the effects of good acid resistance, strong light absorption, and improved application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

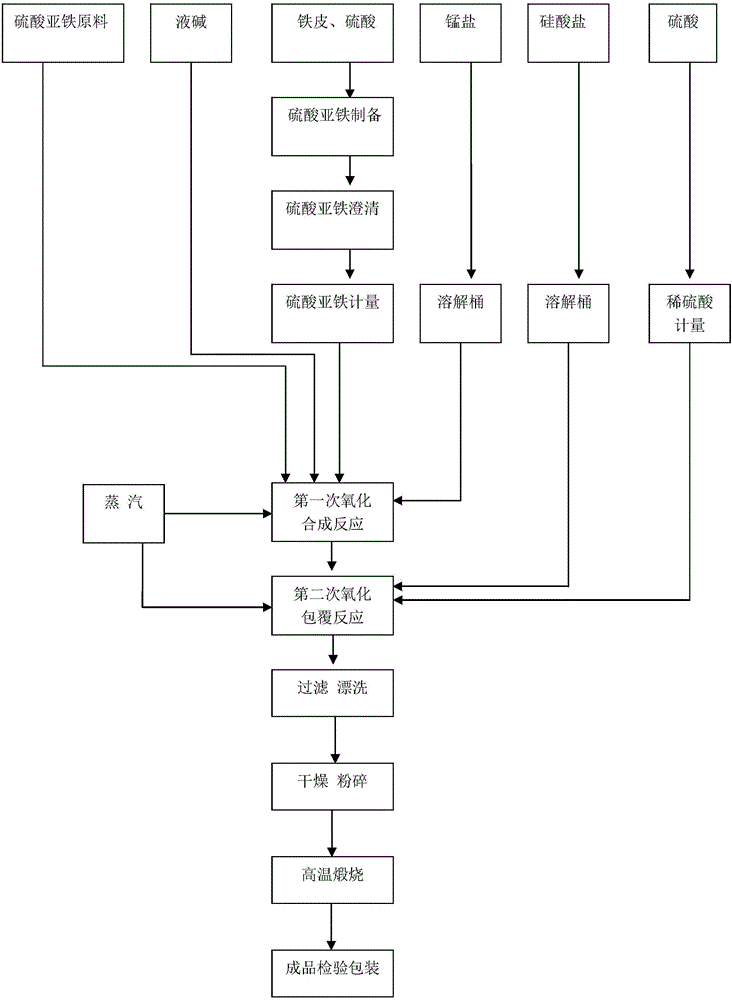

[0023] like figure 1 Shown, the preparation method of high temperature resistant iron oxide black, this preparation method is two stages of oxidative synthesis and high temperature calcination, concrete steps are as follows:

[0024] (1) Oxidative synthesis reaction part

[0025] ① Mixing: Put 100 kg of ferrous sulfate and 100 kg of scraps of iron red and iron yellow into the reaction tank, start stirring and mixing evenly, heat up to 90°C, add 60 kg of manganese sulfate, and then add 30% liquid alkali to adjust the pH When the value is 10, oxidation produces iron oxide black until the material liquid is mature.

[0026] ② Add 5% sodium silicate solution according to the amount of feed solution, react for 10 minutes, measure the pH of the feed solution to 10.0 and react for 30 minutes.

[0027] ③Finally, quickly adjust the pH with dilute sulfuric acid, and pass in air for 1 minute until the pH value stabilizes at 6.0 and react for 30 minutes. After oxidation reaction, the w...

Embodiment 2

[0031] like figure 1 Shown, the preparation method of high temperature-resistant iron oxide black, the preparation method is two stages of oxidation synthesis and high-temperature calcination, the specific steps are as follows:

[0032] (1) Oxidative synthesis reaction part

[0033] ①Mixing: Put 100kg of ferrous sulfate and 100kg of iron sludge scraps into the reaction tank, start stirring and mixing evenly, add 60kg of manganese sulfate, heat up to 90°C, add 30% liquid caustic soda to adjust the pH value to 10, and oxidize to form iron oxide Black until the material liquid is mature.

[0034] ②According to the amount of feed liquid, add 5% sodium silicate solution by mass fraction, react for 10 minutes, measure the pH value as 10.0 and react for 30 minutes.

[0035] ③Finally, quickly adjust the pH with dilute sulfuric acid, and pass in air for 1 minute until the pH value stabilizes at 7.0 and react for 30 minutes. After oxidation reaction, the whole reaction temperature is...

Embodiment 3

[0039] like figure 1 Shown, the preparation method of high temperature resistant iron oxide black, this preparation method is two stages of oxidative synthesis and high temperature calcination, concrete steps are as follows:

[0040] (1) Oxidative synthesis reaction part

[0041] ①Mixing: Put 100kg of ferrous sulfate and 100kg of iron mud scraps into the reaction tank, start stirring and mixing evenly, add 60kg of manganese chloride, heat up to 70°C, add 30% liquid caustic soda to adjust the pH value to 10, and oxidize to form oxidized Iron black until the feed liquid is mature.

[0042] ②According to the amount of feed liquid, add 5% sodium silicate solution by mass fraction, react for 10 minutes, measure the pH value as 10.0 and react for 30 minutes.

[0043] ③Finally, quickly adjust the pH with dilute sulfuric acid, and pass in air for 1 minute until the pH value stabilizes at 8.0 and react for 30 minutes. After oxidation reaction, the whole reaction temperature is 70°C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com