Tantalum oxide chlorine micron cubic crystal photocatalyst as well as preparation method and application thereof

A cubic crystal and photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, tantalum compounds, etc., can solve problems such as product defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 0.6mmol TaCl 5 Dissolve in 15ml of concentrated hydrochloric acid with a mass fraction of 38% until the solution is clear. Add 30ml of glacial acetic acid to the above solution, stir until the bubbles disappear; transfer the mixed solution (the molar ratio of HCl to carboxylic acid is 1:2.82) into a 50ml reactor; heat the reactor at 200°C for 10 hours, Then cool naturally, collect the precipitate, and dry it in a desiccator at normal temperature to obtain a micron cubic crystal of tantalum oxychloride.

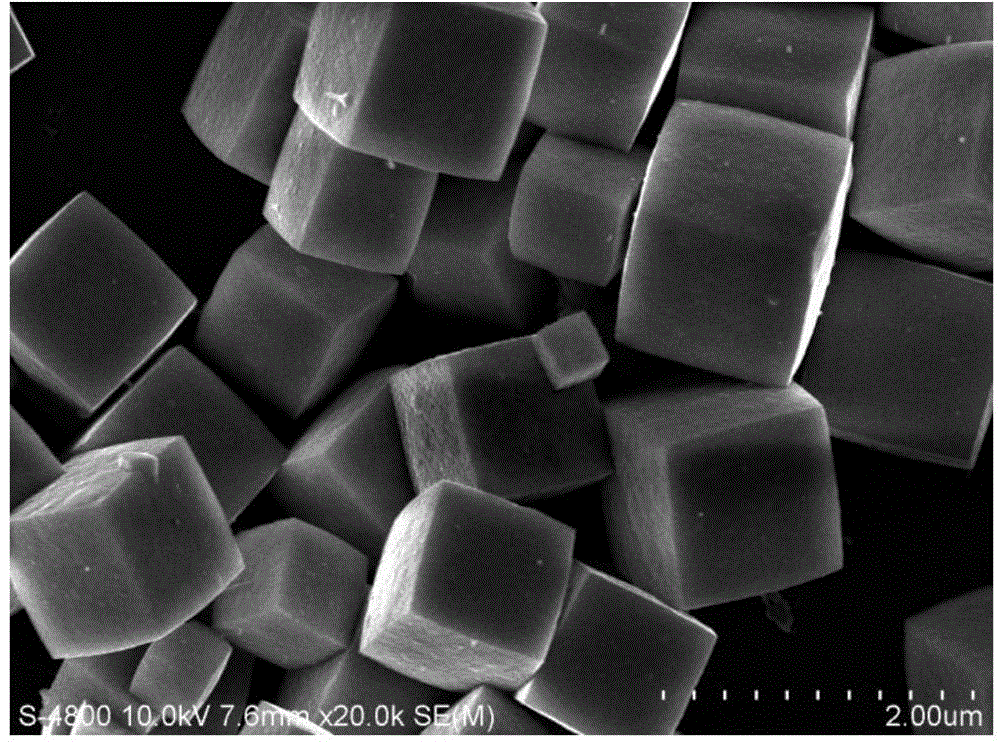

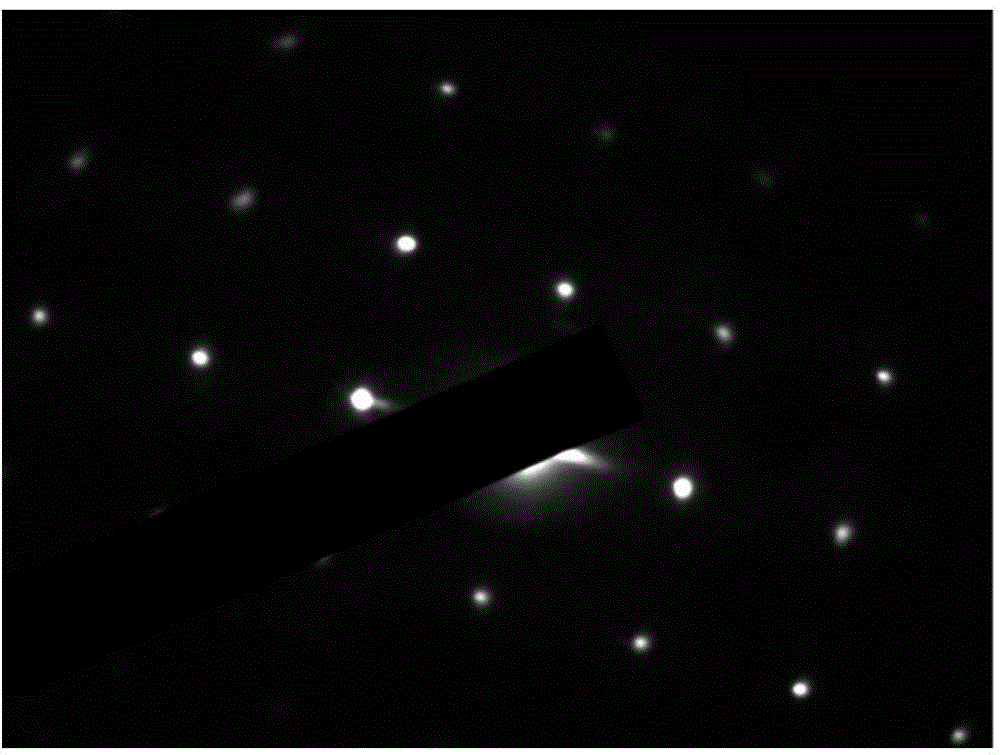

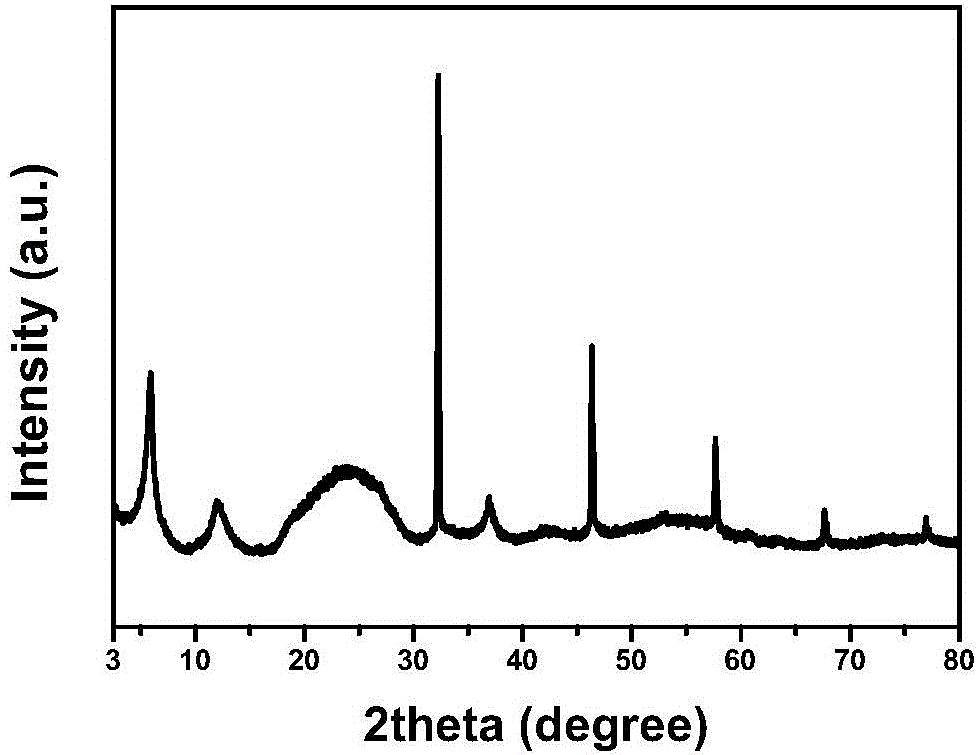

[0039] Refer to attached Figure 1-6 shown by figure 1 From the field emission scanning electron microscope image of the product of this example, it can be seen that the obtained product is a micron cube of 0.2-1.5 μm; figure 2 The array-like spots in the electron diffraction pattern pool indicate that the micron cube has a single crystal property; image 3 Powder X-ray Diffraction Pattern and Figure 4 X-ray photoelectron spectroscopy combined with XRF characteri...

Embodiment 2

[0043] Adjust the temperature in Example 1 to 100°C (that is, heating at 200°C is changed to heating at 100°C), repeat the steps in Example 1 above, and obtain the product, which is a micron cube of 1.2-3 μm, The structure and morphology of the product were characterized by field emission scanning electron microscopy and X-ray energy spectroscopy, such as Figure 8 As shown, it shows that the obtained product is micron cubic crystal of tantalum oxychloride, and the molecular formula is TaO (5-x) / 2 Cl x (x=0.64).

Embodiment 3

[0045] TaCl in embodiment 1 5 The amount of the substance is increased to 1mmol, and the steps of the above example 1 are repeated to obtain the product. The resulting product is a micron cube of 0.7-1.5 μm, and the structure and morphology of the product are carried out by field emission scanning electron microscope and X-ray energy spectrum. representation, such as Figure 9 As shown, it shows that the obtained product is micron cubic crystal of tantalum oxychloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com