Method for compounding all-silicon ZSM-5 molecular sieve by utilizing all-silicon Beta crystallized mother liquor

A technology of ZSM-5 and crystallization mother liquor, which is applied in the direction of borocarbane silicone crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problem of increasing the difficulty of sewage treatment, excessive suspended matter in effluent sewage, and increasing The cost of filter residue treatment and other issues can be shortened to shorten the synthesis time, improve the synthesis efficiency and shorten the crystallization cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 3.7gNaOH is added to all-silicon Beta crystallization mother liquor 150g (SiO 2 : 65g / L; Na 2 O: 24.9g / L; template agent: 85g / L), stirred until a clear solution. Slowly add 240g of silica sol dropwise to the above mixed solution under magnetic stirring to form silicate gel A; transfer the silicate gel to a polytetrafluoroethylene-lined stainless steel crystallization kettle, crystallize at 120°C After 24 hours of melting, the product is separated to obtain the solid silicon ZSM-5 molecular sieve and the mother liquor. The solid silicon ZSM-5 molecular sieve is washed, dried at 85°C for 10 hours, and calcined at 550°C for 6 hours to obtain the original powder of all silicon ZSM-5 molecular sieve. ;

Embodiment 2

[0035]3.7gNaOH is added to all-silicon Beta crystallization mother liquor 150g (SiO 2 : 65g / L; Na 2 O: 24.9g / L; template agent: 85g / L), stirred until a clear solution. Slowly add 240g of silica sol dropwise to the above mixed solution under magnetic stirring to form silicate gel A; transfer the silicate gel to a polytetrafluoroethylene-lined stainless steel crystallization kettle, crystallize at 140°C After 20 hours of melting, the product is separated to obtain the all-silicon ZSM-5 molecular sieve solid and mother liquor, and the all-silicon ZSM-5 molecular sieve solid is washed, dried at 85°C for 10 hours, and roasted at 550°C for 6 hours to obtain the original powder of all-silicon ZSM-5 molecular sieve ;

Embodiment 3

[0039] 3.7gNaOH is added to all-silicon Beta crystallization mother liquor 150g (SiO 2 : 65g / L; Na 2 O: 24.9g / L; template agent: 85g / L), stirred until a clear solution. Slowly add 240g of silica sol dropwise to the above mixed solution under magnetic stirring to form silicate gel A; transfer the silicate gel into a polytetrafluoroethylene-lined stainless steel crystallization kettle, crystallize at 180°C 16 hours; the product is separated to obtain the all-silicon ZSM-5 molecular sieve solid and mother liquor, the all-silicon ZSM-5 molecular sieve solid is washed, dried at 85°C for 10 hours, and roasted at 550°C for 6 hours to obtain the original powder of all-silicon ZSM-5 molecular sieve ;

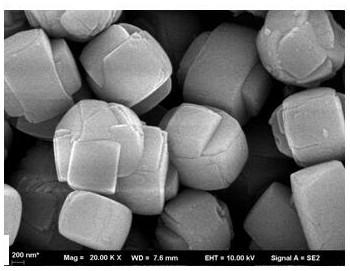

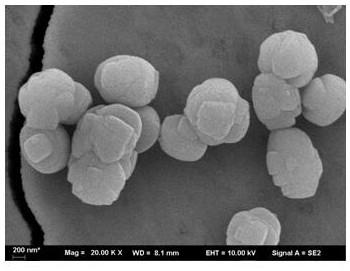

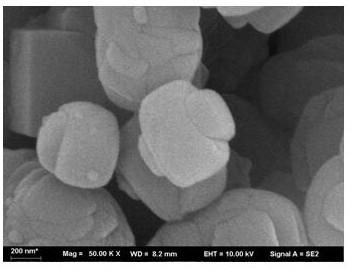

[0040] from figure 1 and figure 2 Compared with the results, it can be clearly seen that the particle size of the ZSM-5 molecular sieve in the unit volume of the reaction kettle obtained by the method of the present invention is obviously reduced, and the number of synthesis is rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com