Ramming material for iron tap channel and preparation method of ramming material

A technology of ramming materials and tapping channels, which is applied in the field of refractory materials, can solve the problems of not meeting the production needs of blast furnaces, shortening the service life of iron channel materials, and repeating the number of repeated channel repairs, etc., to achieve perfect product structure, slag resistance and erosion resistance Excellent performance and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

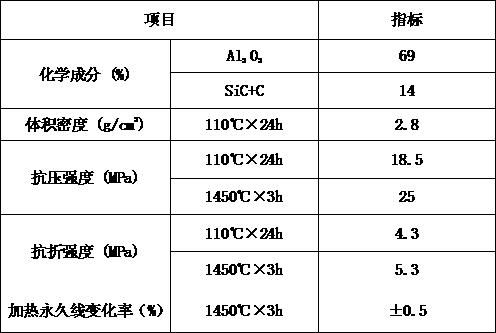

Embodiment 1

[0037] A kind of ramming material for tapping trench, including raw materials in the following proportions: high-quality bauxite 54%, of which (high-quality bauxite 0.1-1mm18%, high-quality bauxite 1-3mm16%, high-quality bauxite 3 -5mm20%), brown corundum 13%, silicon carbide 12%, Guangxi mud 3%, kyanite 3%, alumina superfine powder 7%, spodumene powder 1%, antioxidant 1%, plasticizer 0.7% , environmental protection resin 5%, sintering agent 0.3%.

[0038] A kind of preparation method for the ramming material of tapping trough, comprises the following steps:

[0039] (1) Prepare the main ingredients according to the above ratio, high-quality bauxite, brown corundum, and silicon carbide, weigh them and add them to the mixer for 5-10 minutes;

[0040] (2) Add the above-mentioned auxiliary materials according to the above ratio, spodumene powder, Guangxi mud, kyanite, alumina superfine powder, anti-oxidant and stir evenly;

[0041] (3) Add plasticizer, environmental protection ...

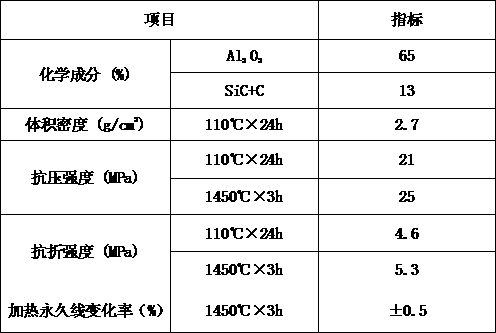

Embodiment 2

[0045] A kind of ramming material used for tapping troughs, including raw materials in the following proportions: high-quality bauxite 48%, of which (high-quality bauxite 0.1-1mm15%, high-quality bauxite 1-3mm16%, high-quality bauxite 3 -5mm17%), brown corundum 18%, silicon carbide 11%, Guangxi mud 3%, kyanite 4%, alumina superfine powder 6%, spodumene powder 1%, antioxidant 2%, plasticizer 0.6% , environmental protection resin 6%, sintering agent 0.4%.

[0046] A kind of preparation method for the ramming material of tapping trough, comprises the following steps:

[0047] (1) Prepare the main ingredients according to the above ratio, high-quality bauxite, brown corundum, and silicon carbide, weigh them and add them to the mixer for 5-10 minutes;

[0048] (2) Add the above-mentioned auxiliary materials according to the above ratio, spodumene powder, Guangxi mud, kyanite, alumina superfine powder, anti-oxidant and stir evenly;

[0049] (3) Add plasticizer, environmental prote...

Embodiment 3

[0053] A kind of ramming material used for tapping troughs, including raw materials in the following proportions: high-quality bauxite 43% of which (high-quality bauxite 0.1-1mm16%, high-quality bauxite 1-3mm15%, high-quality bauxite 3- 5mm12%), brown corundum 22%, silicon carbide 11%, Guangxi mud 4%, kyanite 3%, alumina superfine powder 5%, spodumene powder 1%, antioxidant 3%, plasticizer 0.5%, Environmentally friendly resin 7%, sintering agent 0.5%.

[0054] A kind of preparation method for the ramming material of tapping trough, comprises the following steps:

[0055] (1) Prepare the main ingredients according to the above ratio, high-quality bauxite, brown corundum, and silicon carbide, weigh them and add them to the mixer for 5-10 minutes;

[0056] (2) Add the above-mentioned auxiliary materials according to the above ratio, spodumene powder, Guangxi mud, kyanite, alumina superfine powder, anti-oxidant and stir evenly;

[0057] (3) Add plasticizer, environmental protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com