Preparation method for 1-phenyl-5-mercaptotetrazole

A technology of mercaptotetrazolium and phenyl, which is applied in the field of preparation of 1-phenyl-5-mercaptotetrazolium, can solve the problems of complex operation, many types of reagents, and many reaction steps, and achieve simple operation and low production cost Low, little environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

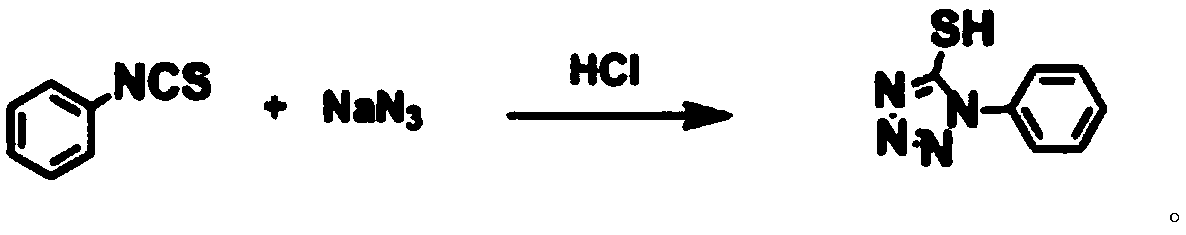

[0020] The invention provides a preparation method of 1-phenyl-5-mercaptotetrazolium, comprising the following steps:

[0021] Under the condition of 90~95 ℃, the sodium azide aqueous solution is mixed with phenyl isothiocyanate and then kept for 110~130min to carry out the azide reaction to obtain the azide reaction product feed liquid;

[0022] The azide reaction product feed liquid is mixed with water, the pH value of the obtained material is adjusted with hydrochloric acid to be 3.0-5.0, and acidified for 50-70 min to obtain 1-phenyl-5-mercaptotetrazolium.

[0023] In the present invention, under the condition of 90-95 DEG C, the sodium azide aqueous solution is mixed with phenyl isothiocyanate, and then the azide reaction is carried out for 110-130 min under heat preservation to obtain the azide reaction product feed liquid. In the present invention, the mass content of sodium azide in the sodium azide aqueous solution is preferably 8-12%, more preferably 9-10%. In the p...

Embodiment 1

[0042] Mix 10.0kg of purified water with 1.0kg of sodium azide to obtain an aqueous solution of sodium azide, heat it to 90°C, add 2.0kg of phenyl isothiocyanate dropwise under stirring conditions, after the dropwise addition, keep warm for 2 hours , add 0.1kg of activated carbon to the obtained system, continue to stir for 30min, remove the activated carbon by filtration, and obtain the azidation reaction product liquid;

[0043] The azidation reaction product liquid was mixed with 3 kg of purified water, and 1.5 kg of hydrochloric acid with a mass concentration of 31% was added dropwise under stirring conditions, so that the pH value of the obtained material was 4.8, and acidification treatment was carried out at 26°C for 60 minutes; The obtained system was centrifuged, and the obtained crude product was washed with 2 kg of purified water, centrifuged, and the obtained solid material was dried under reduced pressure to obtain 2.4 kg of finished 1-phenyl-5-mercaptotetrazole wi...

Embodiment 2

[0045] Mix 10.0kg of purified water with 1.0kg of sodium azide to obtain an aqueous solution of sodium azide, heat it to 95°C, add 2.05kg of phenyl isothiocyanate dropwise under stirring conditions, after the dropwise addition, keep warm for 2 hours , add 0.1kg of activated carbon to the obtained system, continue to stir for 30min, remove the activated carbon by filtration, and obtain the azidation reaction product liquid;

[0046] The azidation reaction product liquid was mixed with 3 kg of purified water, and 1.5 kg of hydrochloric acid with a mass concentration of 31% was added dropwise under stirring conditions, so that the pH value of the obtained material was 3.5, and the acidification treatment was carried out at 30° C. for 60 minutes; The obtained system was centrifuged, the obtained crude product was washed with 2 kg of purified water, centrifuged, and the obtained solid material was dried under reduced pressure to obtain 2.452 kg of 1-phenyl-5-mercaptotetrazolium fini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com