Weather-resistant graphene electricity-conduction and heat-conduction composite material and preparation method thereof

A technology of electrical and thermal conduction and composite materials, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of missing carbon atoms, low brittleness, and no graphene, so as to improve thermal stability and dispersibility, improve Stretch resistance, enhanced interfacial compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

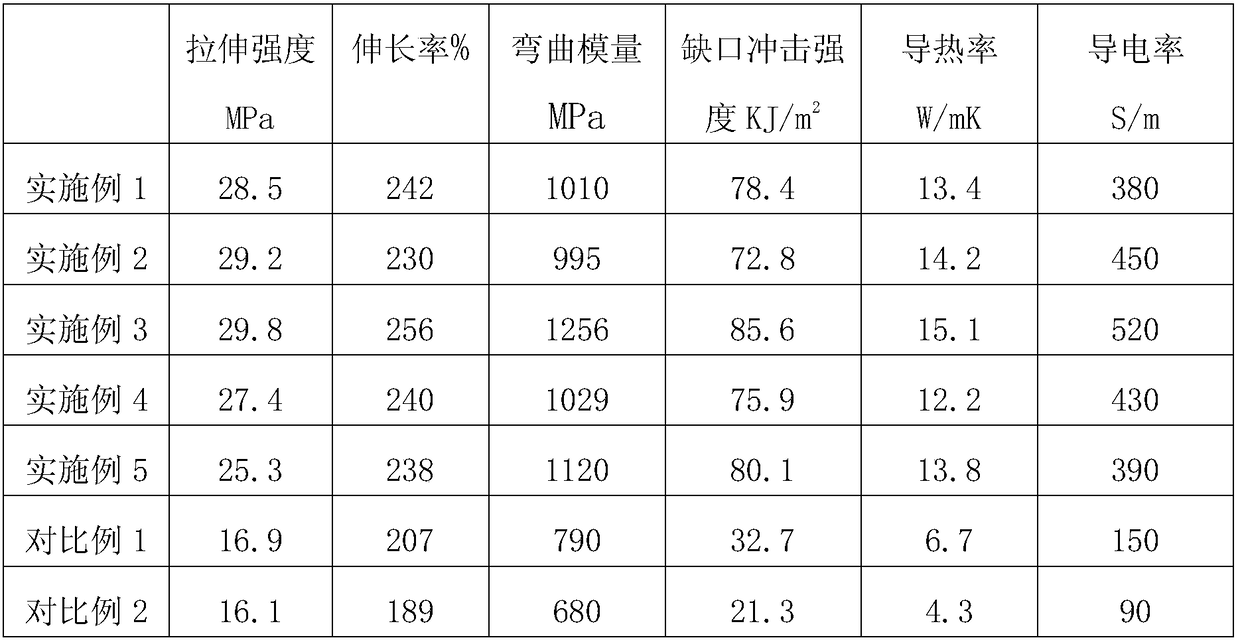

Examples

Embodiment 1

[0026] The weather-resistant graphene conductive and thermally conductive composite material in this embodiment is made of the following raw materials in parts by weight: 20 parts of modified graphene, 15 parts of modified elastomer, 10 parts of polymethyl methacrylate, 10 parts of polyimide resin, 18 parts of conductive filler, 1 part of benzoyl peroxide, 1 part of lubricant, 1 part of crosslinking agent, 1 part of antioxidant;

[0027] Wherein, the modification method of modified graphene is: adopt graphite powder as raw material, prepare graphite oxide with improved Hummers method, take 1g graphite oxide and ultrasonically disperse in 500mLN, N-dimethylformamide, obtain dispersion liquid, Add 12g of isophorone diisocyanate to the dispersion liquid, pass through nitrogen protection, react at 82°C for 25h, adjust the pH of the dispersion liquid to between 9-10 with ammonia water, then raise the temperature to 93°C, add 1.2 g hydrazine hydrate for 2 h, after the reaction, use ...

Embodiment 2

[0035] The weather-resistant graphene conductive and thermally conductive composite material in this embodiment is made of the following raw materials in parts by weight: 30 parts of modified graphene, 25 parts of modified elastomer, 15 parts of polymethyl methacrylate, 16 parts of polyimide resin, 26 parts of conductive filler, 1.5 parts of benzoyl peroxide, 3 parts of lubricant, 2 parts of crosslinking agent, 2.5 parts of antioxidant;

[0036] Wherein, the modification method of modified graphene is: adopt graphite powder as raw material, prepare graphite oxide with improved Hummers method, take 1g graphite oxide and ultrasonically disperse in 500mLN, N-dimethylformamide, obtain dispersion liquid, Add 12g of isophorone diisocyanate to the dispersion liquid, pass through nitrogen protection, react at 82°C for 25h, adjust the pH of the dispersion liquid to between 9-10 with ammonia water, then raise the temperature to 93°C, add 1.2 g hydrazine hydrate for 2 h, after the reaction...

Embodiment 3

[0044] The weather-resistant graphene conductive and thermally conductive composite material in this embodiment is made of the following raw materials in parts by weight: 25 parts of modified graphene, 20 parts of modified elastomer, 13 parts of polymethyl methacrylate, 13 parts of polyimide resin, 22 parts of conductive filler, 1.3 parts of benzoyl peroxide, 2 parts of lubricant, 1.5 parts of crosslinking agent, 1.7 parts of antioxidant;

[0045] Wherein, the modification method of modified graphene is: adopt graphite powder as raw material, prepare graphite oxide with improved Hummers method, take 1g graphite oxide and ultrasonically disperse in 500mLN, N-dimethylformamide, obtain dispersion liquid, Add 12g of isophorone diisocyanate to the dispersion liquid, pass through nitrogen protection, react at 82°C for 25h, adjust the pH of the dispersion liquid to between 9-10 with ammonia water, then raise the temperature to 93°C, add 1.2 g hydrazine hydrate for 2 h, after the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com