Sand-fixing composition and preparation method and application thereof

A composition and component technology, applied in application, fertilizer mixture, chemical instruments and methods, etc., can solve the problems of sand fixation, sand soil improvement, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

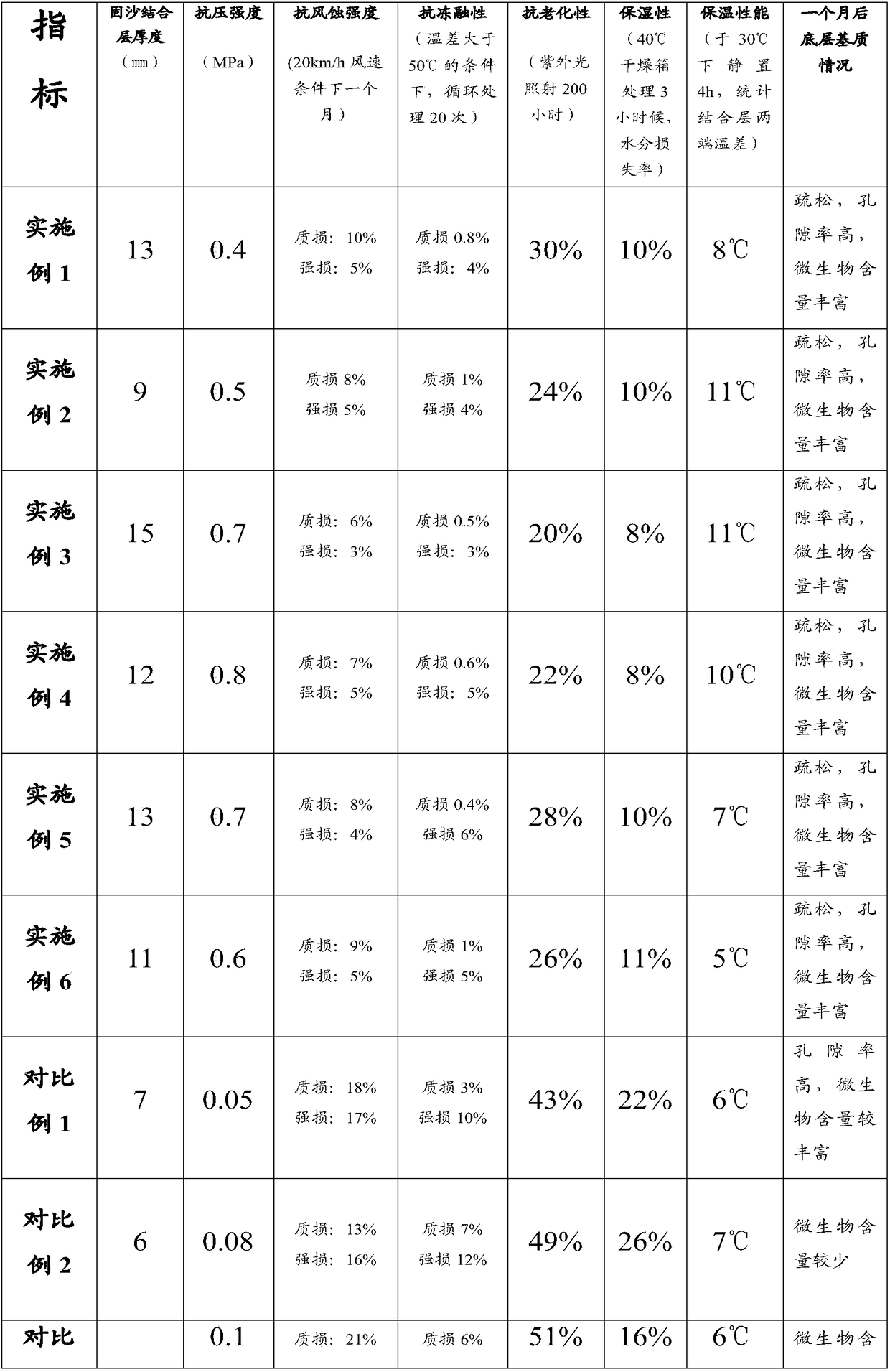

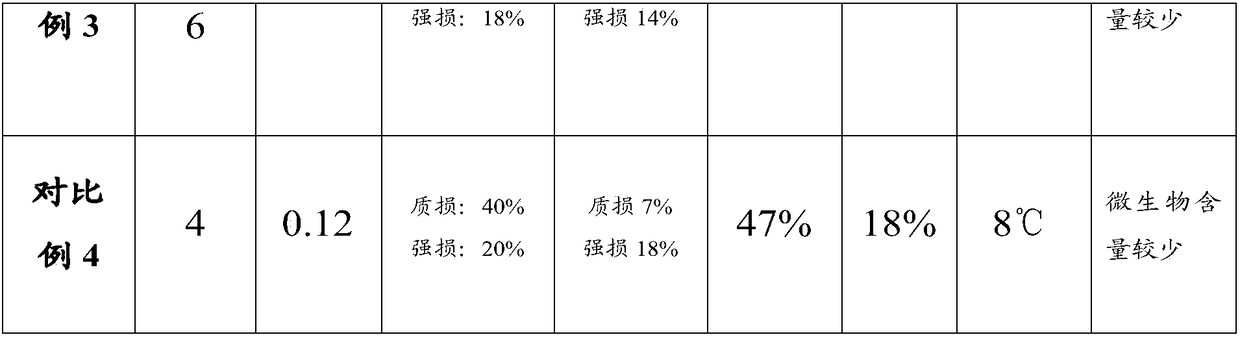

Examples

Embodiment 1

[0063] In terms of parts by weight, the raw material components include: 50 parts of the first material, 10 parts of the second material, 0.5 parts of the microbial liquid, 10 parts of bentonite, 1 part of sawdust, 5 parts of waste paper pulp and 200 parts of water.

[0064] Specifically, the first material mainly consists of the following components:

[0065] 4 parts polyvinyl alcohol, 4 parts styrene, 5 parts methyl methacrylate, 4 parts butyl acrylate, 6 parts ethyl acrylate, 5 parts methyl acrylate, 2 parts acrylic acid, 2 parts methacrylic acid, 3 parts acrylamide Parts, 1 part of sodium styrene sulfonate, 1 part of sodium vinyl sulfonate, 1 part of allyloxy nonylphenol polyoxyethylene ether ammonium sulfate, 1 part of allyloxy hydroxypropane sulfonate, 1 part of methacrylic acid hydroxy 1 part of sodium propyl sulfonate, 1 part of sodium 4-enbutoxy-2-hydroxypropane sulfonate, 1 part of sodium 2-acrylamide-2,2-dimethylethanesulfonate, 2-acrylamido- 1 part of 2-methyl-propyl a...

Embodiment 2

[0078] In terms of parts by weight, the raw material components include: 80 parts of the first material, 30 parts of the second material, 2 parts of microbial liquid, 20 parts of bentonite, 8 parts of sawdust, 10 parts of waste paper pulp and 300 parts of water.

[0079] Specifically, the first material mainly consists of the following components:

[0080] 6 parts of polyvinyl alcohol, 5 parts of styrene, 6 parts of methyl methacrylate, 5 parts of butyl acrylate, 7 parts of ethyl acrylate, 7 parts of methyl acrylate, 3 parts of acrylic acid, 3 parts of methacrylic acid, 6 parts of acrylamide Parts, 1.5 parts of sodium styrene sulfonate, 1.5 parts of sodium vinyl sulfonate, 2 parts of allyloxy nonylphenol polyoxyethylene ether ammonium sulfate, 1.5 parts of sodium allyloxy isoprolate, hydroxy methacrylate 2 parts of sodium propyl sulfonate, 1.5 parts of sodium 4-enbutoxy-2-hydroxypropane sulfonate, 1.5 parts of sodium 2-acrylamide-2,2-dimethylethanesulfonate, 2-acrylamido- 1.5 part...

Embodiment 3

[0093] In terms of parts by weight, the raw material components include: 62 parts of the first material, 21 parts of the second material, 1 part of microbial liquid, 15 parts of bentonite, 5 parts of sawdust, 8 parts of waste paper pulp and 240 parts of water.

[0094] Specifically, the first material mainly consists of the following components:

[0095] 4 parts polyvinyl alcohol, 4 parts styrene, 5 parts methyl methacrylate, 5 parts butyl acrylate, 7 parts ethyl acrylate, 7 parts methyl acrylate, 3 parts acrylic acid, 2 parts methacrylic acid, 4 parts acrylamide Parts, 1 part of sodium styrene sulfonate, 1 part of sodium vinyl sulfonate, 2 parts of allyloxy nonylphenol polyoxyethylene ether ammonium sulfate, 1 part of allyloxy hydroxypropane sulfonate, 1 part of methacrylic acid hydroxy 1 part of sodium propyl sulfonate, 1.5 parts of sodium 4-enbutoxy-2-hydroxypropane sulfonate, 1.5 parts of sodium 2-acrylamide-2,2-dimethylethanesulfonate, 2-acrylamido- 1 part of 2-methyl-propyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com