Memristor switch device based on a-TSC:O ceramic film and preparation method thereof

A technology of ceramic thin film and switching device, which is applied in the field of memristive switching device based on a-TSC:O ceramic thin film and its preparation, can solve problems such as research reports on applications in the field of optoelectronics that have not been seen, and achieve good near-infrared transmittance , good resistance performance, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

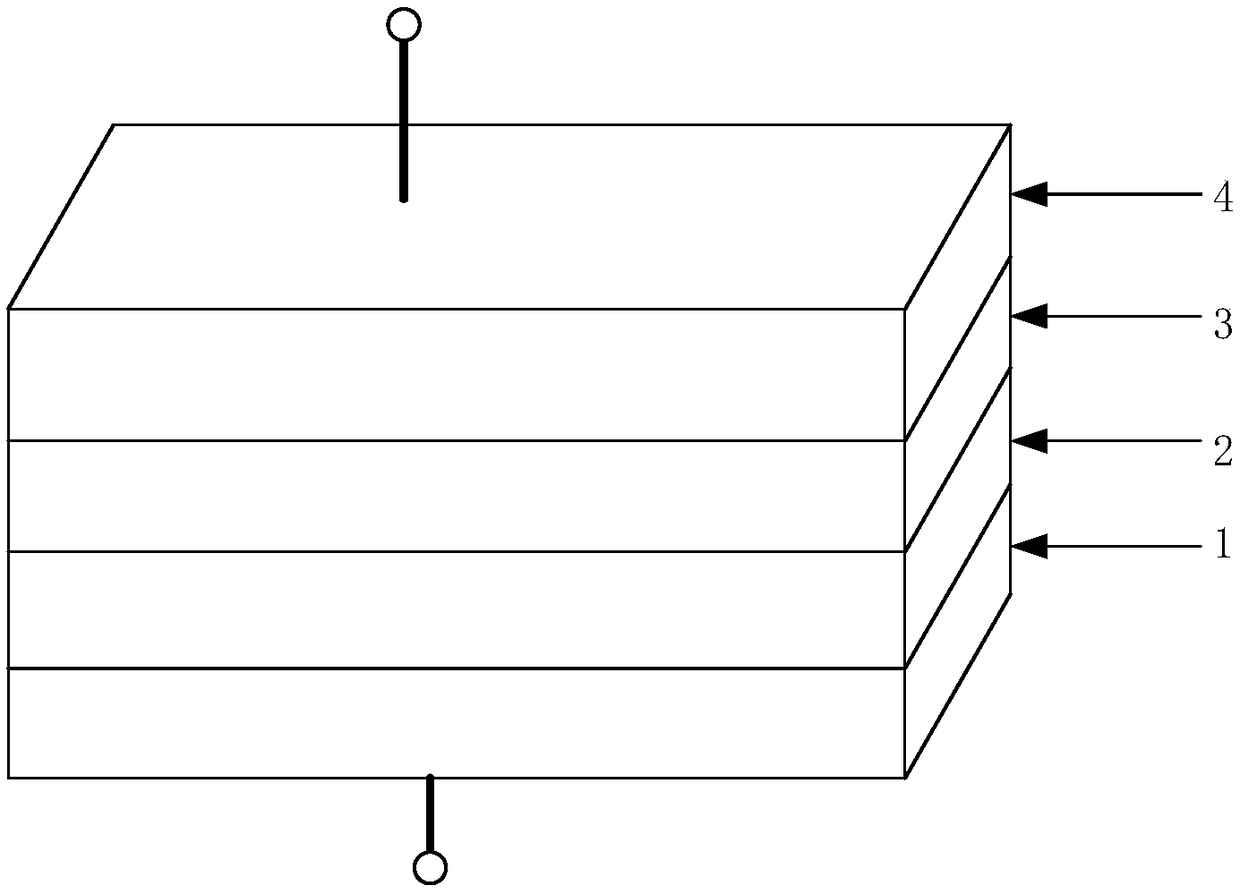

[0031] This embodiment provides a memristive switching device, such as figure 1 As shown, the structure from bottom to top is "ITO glass 1, a-TiO x Film 2, a-TSC:O film 3, a-TSC film 4" vertical four-layer structure, "a-TiO x The film 2 / a-TSC:O film 3" double layer structure is used as the double resistance layer (that is, the dielectric layer of the memristive switching device).

[0032] This embodiment provides a method for manufacturing the above memristive switch device, and the manufacturing process includes the following steps:

[0033] Step A: Prepare the ITO glass slide 1 as a transparent substrate with a bottom electrode, and perform cleaning and drying treatments according to standard processes;

[0034] Step B: using a titanium target as a raw material target, oxygen and argon as working gases, and depositing a-TiOx film 2 on the ITO glass substrate 1 as the first resistive layer by reactive radio frequency sputtering;

[0035] Step C: Use Ti 3 SiC 2 Polycrystalline powder i...

Embodiment 2

[0052] This embodiment provides a method for manufacturing a memristive switch device, and the manufacturing process includes the following steps:

[0053] Step A: Prepare a K9 glass substrate as a transparent substrate, and perform cleaning and drying treatments according to standard processes; then deposit an ITO film on it as a bottom electrode;

[0054] Step B: Using a titanium target as a raw material target, oxygen and argon as working gases, and depositing a-TiOx film on the ITO film by reactive radio frequency sputtering as the first resistive layer;

[0055] Step C: Use Ti 3 SiC 2 Polycrystalline powder is used as the raw material target, oxygen and argon are used as working gases, and a-TSC:O film is deposited on the a-TiOx film by reactive radio frequency sputtering as the second resistive layer. The specific operations are as follows:

[0056] C1: Target preparation:

[0057] Will Ti 3 SiC 2 Add the powder to deionized water and stir evenly to obtain Ti 3 SiC 2 Dispersion, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com