Structure for reducing leakage in gallium nitride-based epitaxial layer and preparation method thereof

A gallium nitride-based, epitaxial layer technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as large leakage current, poor reliability, and complicated production and preparation processes, and achieve short preparation cycles and reduce preparation costs. method, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

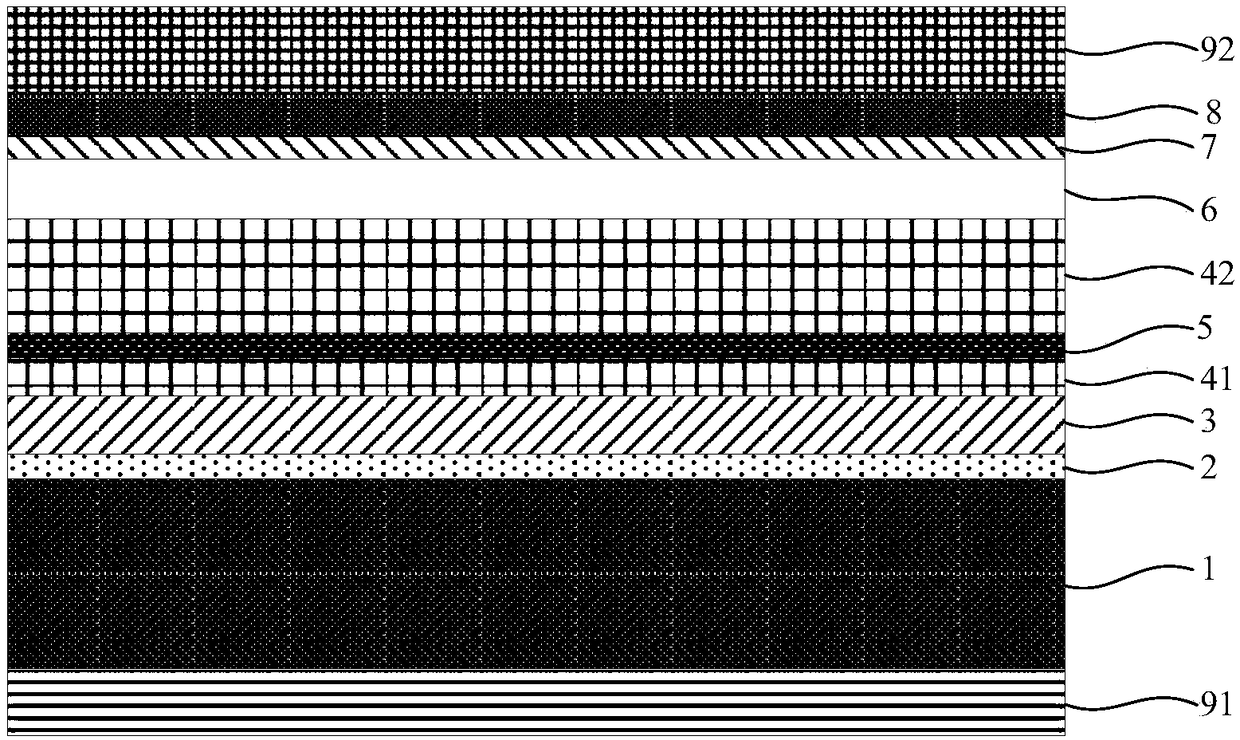

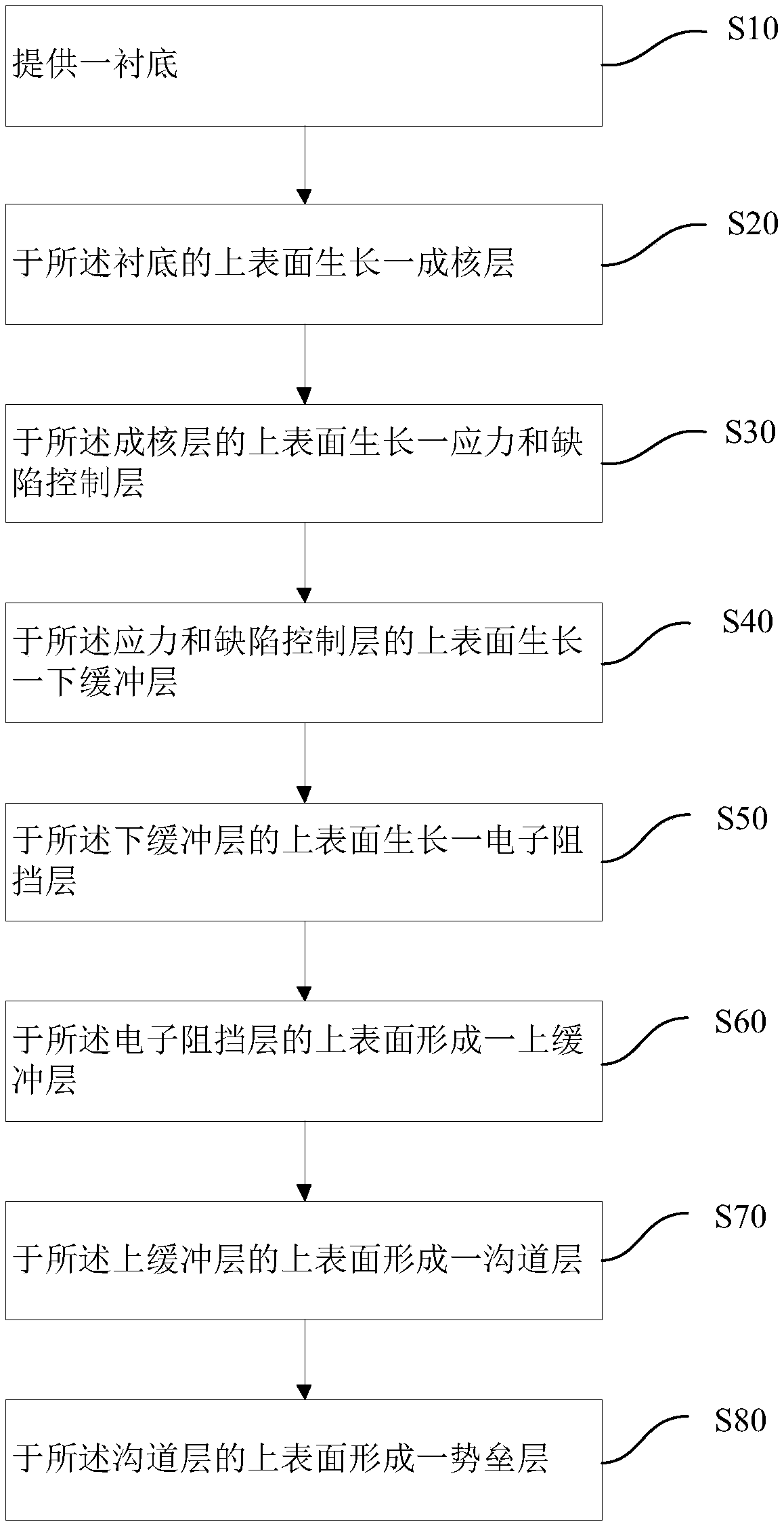

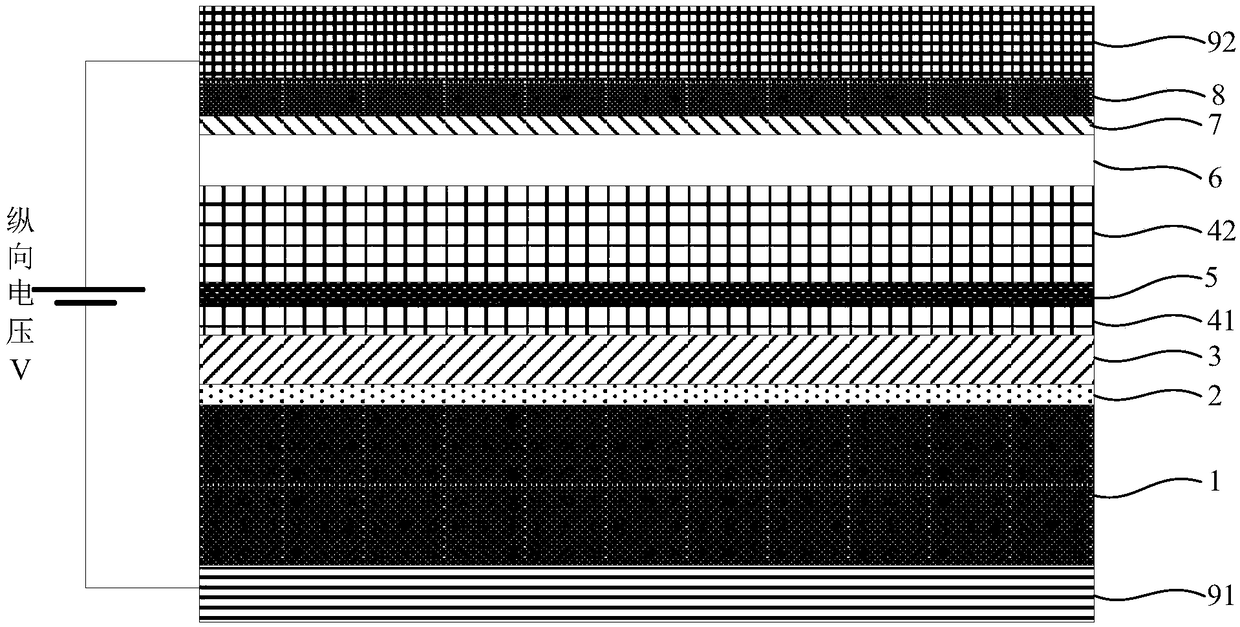

[0074] The present invention also provides a method for preparing the above-mentioned structure for reducing electric leakage in the gallium nitride-based epitaxial layer, such as figure 2 Shown, described preparation method comprises the following steps:

[0075] Step S10 is executed to provide a substrate 1, which may be a semiconductor substrate such as a silicon substrate or a silicon carbide substrate.

[0076] Executing step S20, growing a nucleation layer 2 on the upper surface of the substrate 1, the material of the nucleation layer 2 can be aluminum gallium nitride or aluminum nitride; the thickness of the nucleation layer 2 is 5nm-2μm , more preferably 20nm-1μm, more preferably 50nm-1μm.

[0077] Executing step S30, growing a stress and defect control layer 3 on the upper surface of the nucleation layer 2 for regulating the stress in the gallium nitride-based epitaxial layer and suppressing defects in the gallium nitride-based epitaxial layer The material of the s...

Embodiment 1

[0098] Preparation of a structure in which an electron blocking layer is introduced into a gallium nitride-based epitaxial layer: a silicon substrate is provided, and an aluminum nitride nucleation layer is sequentially grown upward on the surface of the silicon substrate by an epitaxial method, and AlGaN stress and defect control layer, GaN lower buffer layer, AlN electron blocking layer, GaN upper buffer layer, GaN channel layer, AlN insertion layer and AlGaN barrier layer; wherein, the AlN The thickness of the nucleation layer is 180nm-220nm, the thickness of the aluminum gallium nitrogen stress and defect control layer is 580-620nm, the thickness of the gallium nitride buffer layer (upper buffer layer+lower buffer layer) is 2450-2550nm, The thickness of the aluminum nitride electron blocking layer is 3-5nm, the thickness of the gallium nitride channel layer is 290-310nm, the thickness of the aluminum nitride insertion layer is 0.5nm-2nm, the aluminum gallium nitride potenti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com