A kind of lithium battery negative pole and its preparation method and lithium battery

A lithium battery and negative electrode technology, applied in the field of lithium battery negative electrode and its preparation, can solve the problems of affecting battery charge and discharge efficiency, increase of irreversible capacity, consumption of lithium ions, etc., to improve liquid absorption and liquid retention capacity, increase speed and embedding The effect of increasing the charge and discharge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

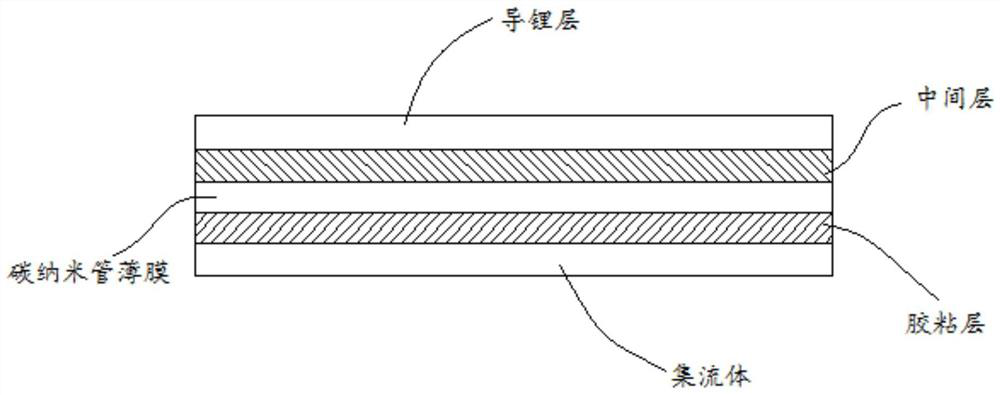

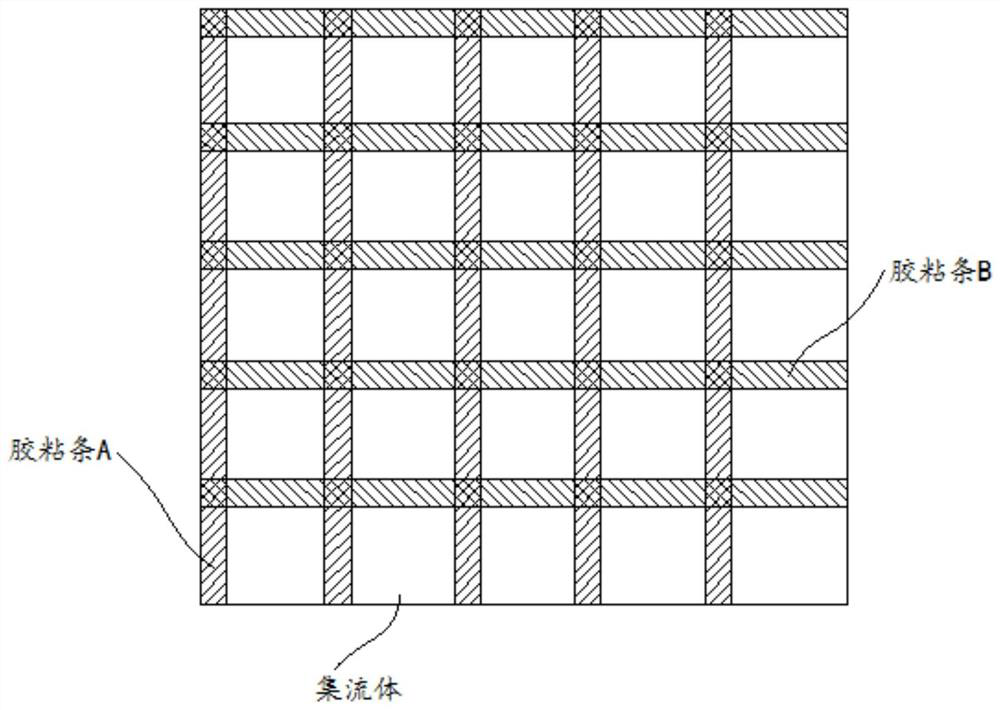

[0039] A lithium battery negative pole, such as figure 1 , figure 2 As shown, it includes a current collector, an adhesive layer, a carbon nanotube film, an intermediate layer, and a lithium-conducting layer. The current collector is coated with an adhesive layer, and the adhesive layer is formed by coating the adhesive in a "well" shape. Network structure, the current collector is bonded with a carbon nanotube film through an adhesive layer, the carbon nanotube film is provided with an intermediate layer, and the intermediate layer is provided with a lithium-conducting layer;

[0040] The current collector is a metal substrate, and the material of the current collector is copper;

[0041] The intermediate layer is a graphene film;

[0042]The lithium-conducting layer is formed by electrostatic spraying of a lithium-conducting spray solution, wherein the lithium-conducting spray solution is configured from a lithium ion conductor material capable of insulating electrons;

...

Embodiment 2

[0059] A lithium battery negative pole, such as figure 1 , figure 2 As shown, it includes a current collector, an adhesive layer, a carbon nanotube film, an intermediate layer, and a lithium-conducting layer. The current collector is coated with an adhesive layer, and the adhesive layer is formed by coating the adhesive in a "well" shape. Network structure, the current collector is bonded with a carbon nanotube film through an adhesive layer, the carbon nanotube film is provided with an intermediate layer, and the intermediate layer is provided with a lithium-conducting layer;

[0060] The current collector is a metal substrate, and the material of the current collector can be selected from one of copper, gold, or silver;

[0061] The intermediate layer is a graphene film;

[0062] The lithium-conducting layer is formed by electrostatic spraying of a lithium-conducting spray solution, wherein the lithium-conducting spray solution is configured from a lithium ion conductor m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com