Switch cabinet condensation prevention intelligent detection and control system

A technology of intelligent detection and control system, applied in the direction of substation/distribution device casing, etc., can solve the problem of accelerated aging of equipment in the cabinet, and achieve the effects of excellent mechanical performance and insulation performance, simple synthesis, and enhanced stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

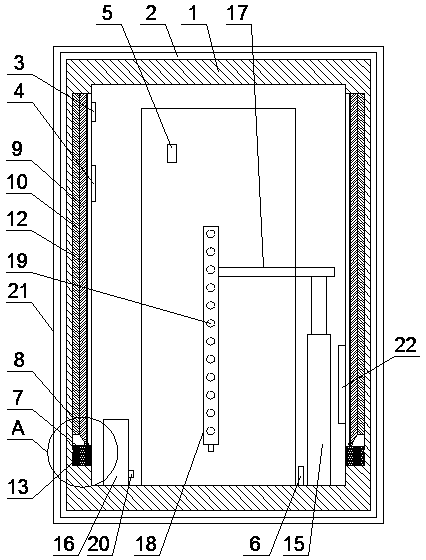

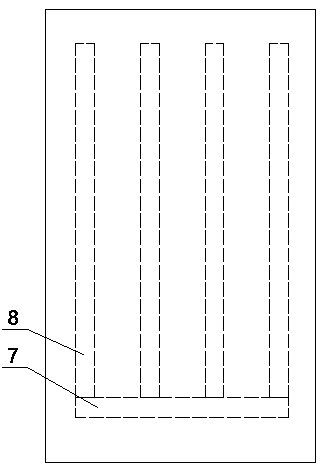

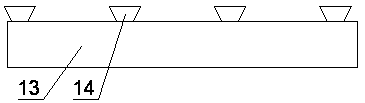

[0037] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a switch cabinet anti-condensation intelligent detection and control system includes a cabinet body 1, the outer surface of the cabinet body 1 is provided with an insulation layer 2, and the inner wall of the cabinet body 1 is provided with a condensation generating mechanism. A first temperature sensor 3 is arranged on the inner wall of the body 1, a dew point meter 4 for detecting the dew point temperature of the internal air is arranged in the cabinet body 1, a second temperature sensor 5 is arranged on the outer surface of the electrical equipment in the cabinet body 1, and the A drying mechanism for drying electrical equipment is arranged in the cabinet body 1, and a PLC controller 6 is arranged in the cabinet body 1, and the PLC controller 6 is connected with the first temperature sensor 3, the dew point meter 4, and the second temperature sensor. The sensor 5, the condensation generating mechanis...

Embodiment 2

[0051] The difference from Example 1 is that the waterproof layer 21 contains components and their contents: 16 parts by weight of polyaniline, 2.5 parts by weight of polymethyl methacrylate, 7 parts by weight of chloroform, N,N- 42 parts by weight of dimethylformamide, 16 parts by weight of sodium silicate, 2.8 parts by weight of sodium lauryl sulfate, 8 parts by weight of nano silicon dioxide, 6 parts by weight of sodium methyl silicate, tetrachloroterephthalic acid 3.7 parts by weight of dimethyl ester, 8.9 parts by weight of cinnamaldehyde, 23 parts by weight of acetone, and 48 parts by weight of deionized water.

Embodiment 3

[0053] The difference from Example 1 is that the waterproof layer 21 contains components and their contents: 17 parts by weight of polyaniline, 3 parts by weight of polymethyl methacrylate, 7.5 parts by weight of chloroform, N,N- 44 parts by weight of dimethylformamide, 16.5 parts by weight of sodium silicate, 3 parts by weight of sodium lauryl sulfate, 9 parts by weight of nano silicon dioxide, 6.1 parts by weight of calcium stearate, tetrachloroterephthalic acid di 3.9 parts by weight of methyl ester, 9 parts by weight of polyaspartic acid, 24 parts by weight of acetone, and 50 parts by weight of deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com