Preparation method for hierarchical-pore ZSM-5 zeolite microspheres

A ZSM-5, multi-level pore technology, applied in the directions of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of difficult filtration separation reaction molecular diffusion limitation, difficult filtration separation and other problems, Achieving the effect of good zeolite structure retention, simple and economical method, and good interconnectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

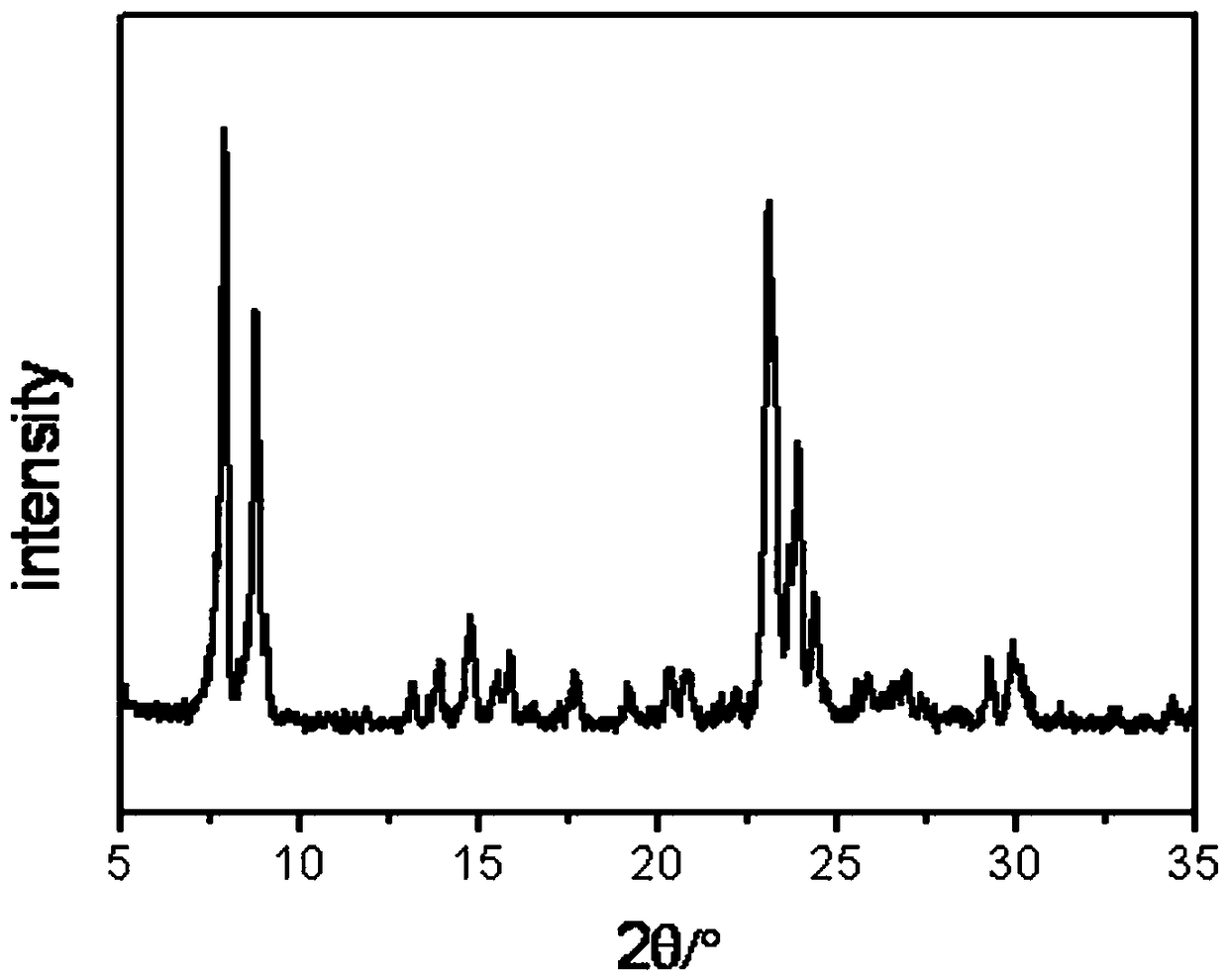

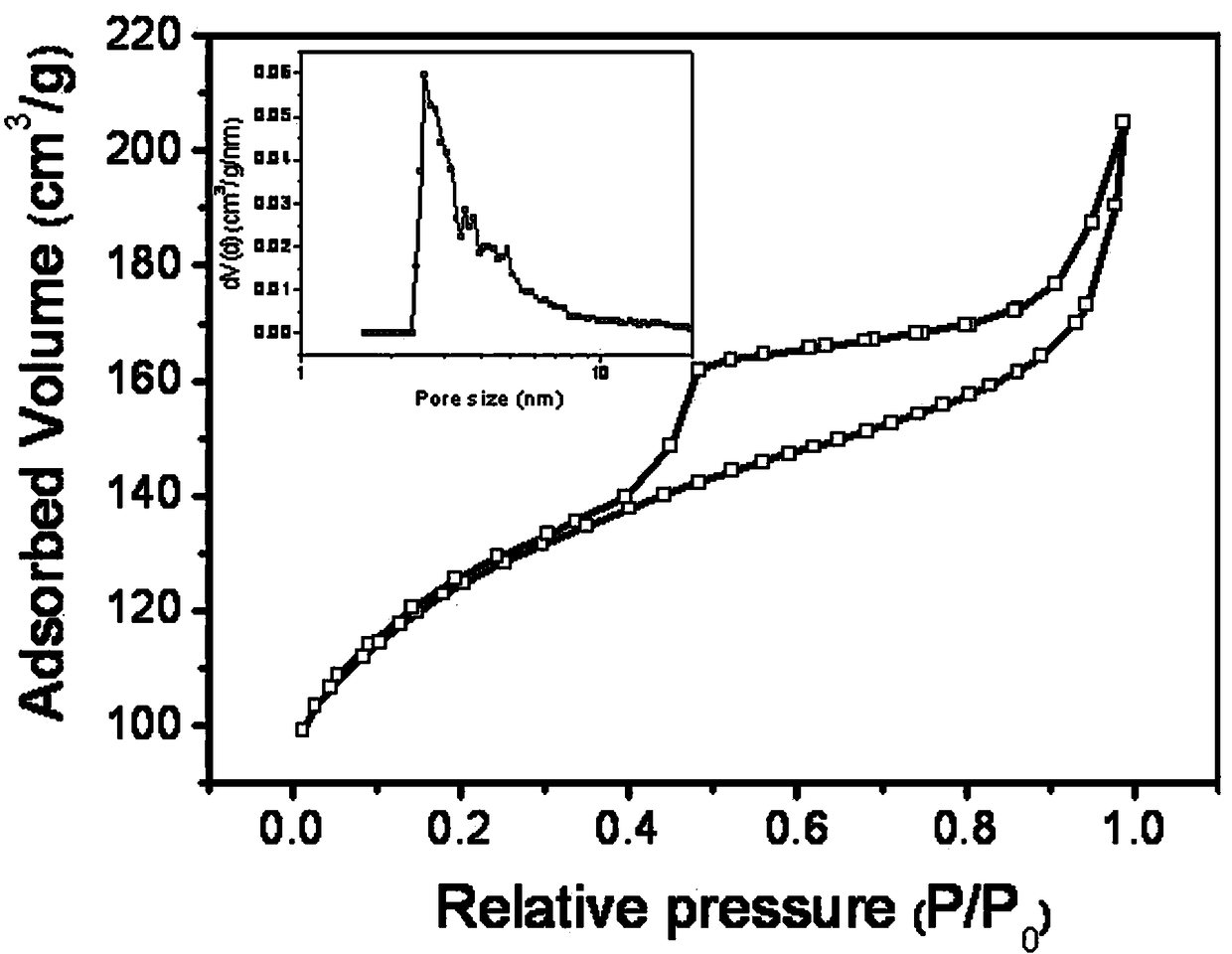

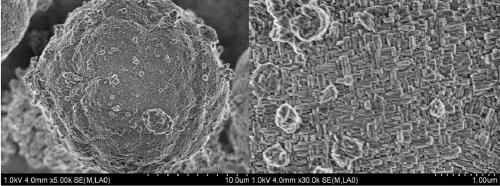

[0016] Embodiment 1: A kind of preparation method of hierarchical porous ZSM-5 zeolite microsphere, with long-chain alkyltrimethylammonium bromide surfactant as a single template, synthesized in NaOH-water-ethanol crystallization system ZSM-5 zeolite microspheres with hierarchical pore structure.

[0017] Specific steps are as follows:

[0018](1) Preparation of gel: according to SiO 2 :Al 2 o 3 : Na 2 O: surfactant CTAB: deionized water: C 2 h 5 The molar ratio of OH is 1:0.0067:0.17:0.04:54.7:2.8. Add 0.35g of surfactant CTAB and 4mL of absolute ethanol to deionized water to obtain a mixture. The mixture is placed in a water bath at 30°C and stirred. After the surfactant is fully dissolved until the solution is clear, add 0.32g of sodium hydroxide and continue to stir. After the solution is clear, add 0.04g of sodium metaaluminate. After stirring, add 1.48g of fumed silica (Aerosil@200), and continue to Stir in a water bath at ℃ for 2 hours to obtain a well-stirred ge...

Embodiment 2

[0022] Example 2: A preparation method of hierarchically porous ZSM-5 zeolite microspheres, using CTAB surfactant as a single template, synthesizing ZSM-5 zeolite with hierarchically porous structure in NaOH-water-ethanol crystallization system Microspheres. Concrete steps are as follows: according to the feeding molar ratio is SiO 2 :Al 2 o 3 : Na 2 O:CTAB:H 2 O: C 2 h 5 OH is 1:0.0067:0.17:0.02:54.7:2.8, and other conditions are the same as in Example 1, only the addition of CTAB is changed to 0.2g to obtain hierarchically porous ZSM-5 zeolite microspheres. Named ZSM-5-2. Its structural properties are shown in Table 1.

Embodiment 3

[0023] Example 3: A preparation method of hierarchically porous ZSM-5 zeolite microspheres, using CTAB surfactant as a single template, and synthesizing ZSM-5 zeolite with hierarchically porous structure in NaOH-water-ethanol crystallization system Microspheres. Concrete steps are as follows: according to the feeding molar ratio is SiO 2 :Al 2 o 3 : Na 2 O:CTAB:H 2 O: C 2 h 5 OH is 1:0.0067:0.17:0.01:54.7:2.8, and other conditions are the same as in Example 1, except that the amount of CTAB added is changed to 0.1 g, that is, hierarchically porous ZSM-5 zeolite microspheres are obtained. Named ZSM-5-3. Its structural properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com