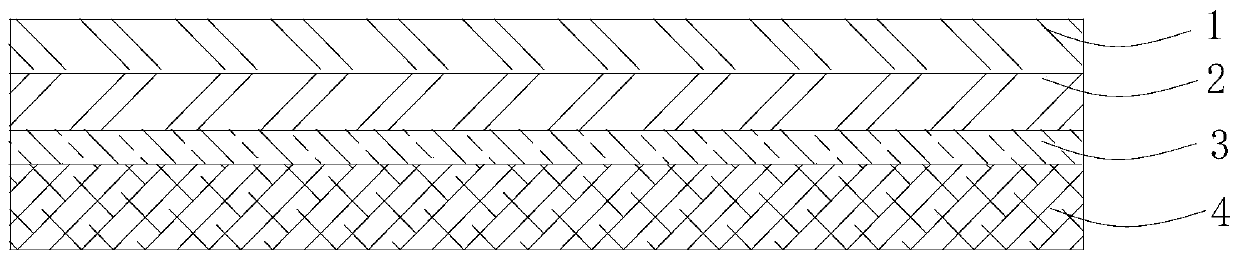

FPC electromagnetic shielding film with polyimide film as insulating layer and preparation method thereof

A technology of polyimide film and electromagnetic shielding film, which is applied in the direction of magnetic/electric field shielding, coating, electrical components, etc., can solve the problems of metal layer cracks, large film thickness, poor weather resistance, etc., and improve the service life , Improve the effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

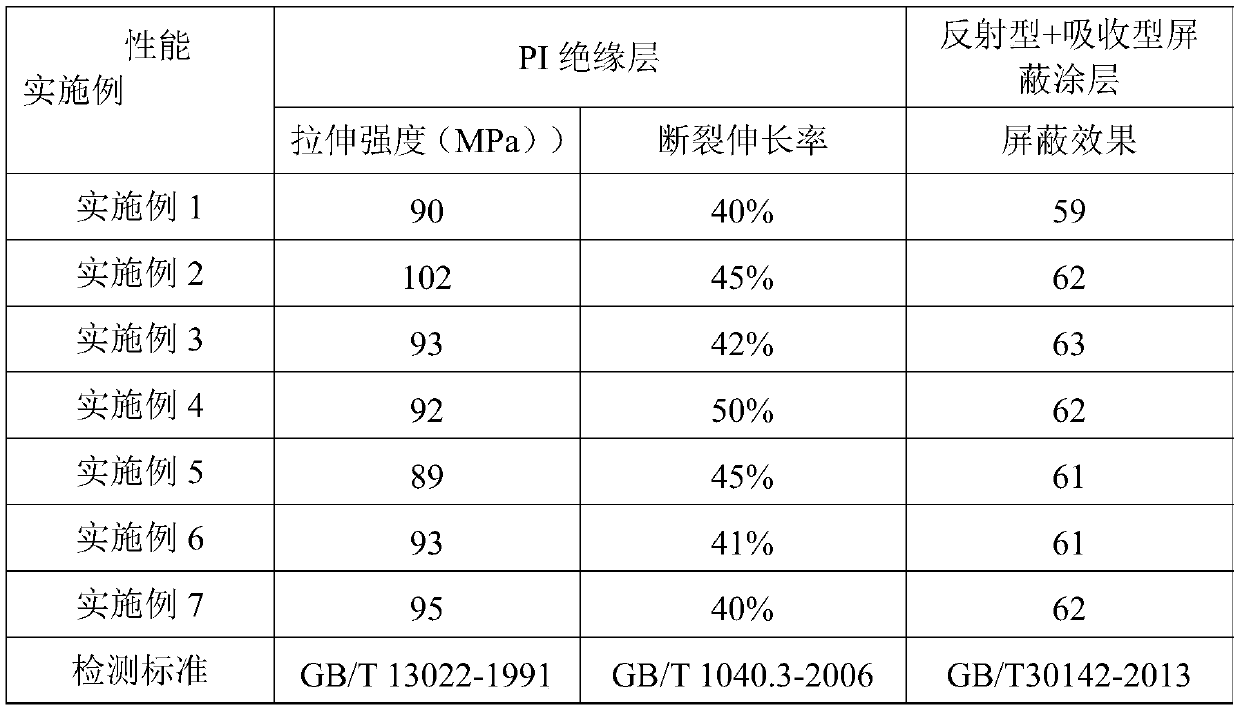

Embodiment 1

[0047] The manufacturing process used in the preparation of the FPC electromagnetic shielding film with the polyimide film as the insulating layer of the present invention is as follows.

[0048] The first step is to prepare black polyimide precursors, reflective electromagnetic shielding coatings and absorptive electromagnetic shielding coatings, which can be prepared in the following order, but the scope of protection is not limited to the following A1, A2, A3 Order.

[0049] A1. Preparation of black polyimide precursor;

[0050] (1) Add 4,4'-diaminodiphenyl ether (ODA for short) into the solvent of dimethylformamide (DMF for short) to make the final total solid content less than 20%. After dissolving, cool to -10℃~ At 5℃, add 4,4-diphenyl ether dianhydride (abbreviated as ODPA), pyromellitic dianhydride (abbreviated as PMDA), biphenyltetracarboxylic dianhydride (abbreviated as BPDA), 3,3'-(between Benzene) diether dianhydride (abbreviated as RsDPA), 3,3',4,4'---benzophenonetetra...

Embodiment 2

[0070] The manufacturing process of the FPC electromagnetic shielding film with polyimide film as the insulating layer in this embodiment is basically the same as that of Example 1, except that the components and ratios of the reflective shielding coating paint in A2 and A3 are:

[0071] The ratio of each raw material of acrylic resin III prepared in A2 is different. The addition amounts of acrylic acid, acrylonitrile, butyl acrylate, and hydroxyethyl acrylate are 7, 35, 20, and 20 parts, respectively; The ratio of raw materials is different. Bisphenol F epoxy resin replaces bisphenol A epoxy resin. The addition amounts of acrylic resin III, bisphenol F epoxy resin, dicyandiamide and diaminodiphenyl sulfone are 50 and 10 respectively. , 5, 5 copies.

[0072] Take flake silver-coated copper powder (Mitsui Metals 1100YP, ball mill, 400 mesh sieving for use; or Fukuda Metals, 10% AgコートCu-HWQ 5μm, for direct use), and ultrasonic activation with activator for 24h to obtain activated shi...

Embodiment 3

[0076] The manufacturing process of the novel composite electromagnetic shielding film for FPC in this embodiment is basically the same as that in embodiment 1, except that the composition ratio of the paint in A2 and A3 is:

[0077] The ratio of each raw material of acrylic resin III prepared in A2 is different. The addition amount of acrylic acid, acrylonitrile, butyl acrylate, and hydroxyethyl acrylate are 15, 50, 30, and 30 parts respectively; The ratio of raw materials is different. Novolac epoxy resin replaces bisphenol A epoxy resin. The addition amount of acrylic resin III, novolac epoxy resin, dicyandiamide, and diaminodiphenyl sulfone are 70, 30, 10, and 10 parts respectively.

[0078] Take flake silver-coated copper powder with a thickness of 1~2μm and a plane size of 3~9μm (Mitsui Metals 1100YP, ball milled, 400 mesh sieved for use; or Fukuda Metals, 10% AgコートCu-HWQ 5μm, used directly), The activator is ultrasonically activated for 24 hours to obtain an activated shield...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com