Sponge rubber of cold-resistant microporous structure and preparation method thereof

A technology of microporous structure and sponge rubber, applied in the field of sponge rubber, can solve the problems of high production cost, large shrinkage rate in the later period, poor dimensional stability, etc., and achieve the effect of reducing production cost, good plasticity and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

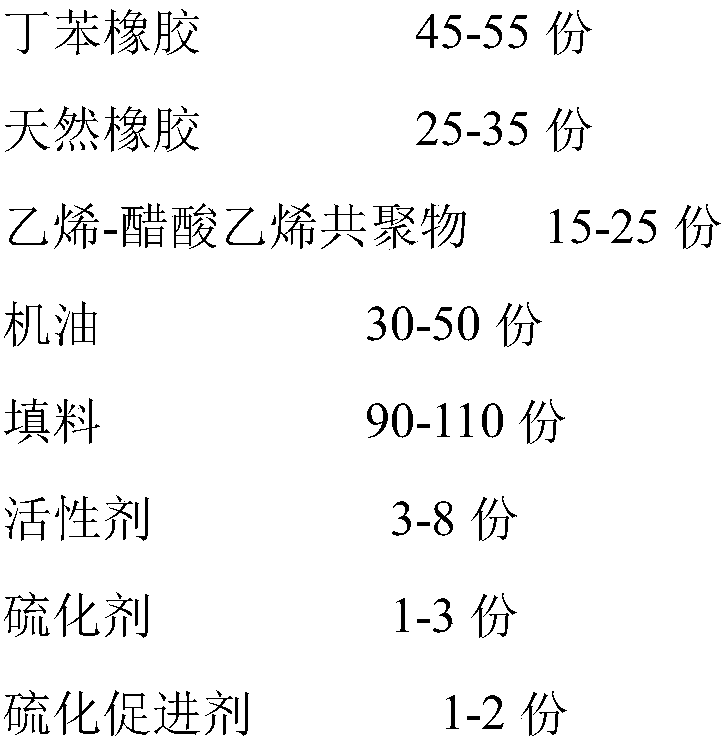

[0032] A cold-resistant microporous sponge rubber, comprising the following components by weight:

[0033]

[0034]

[0035] Among them, styrene-butadiene rubber is HSR (high styrene rubber) with a styrene content of 55%. HSR is a special variety in styrene-butadiene rubber. Obtained by extrusion dehydration and drying, it is white rubber particles that are easily bonded to each other. It is non-toxic, odorless, has the characteristics of low impurity content and stable quality, and reduces the adverse effects caused by impurities in the process of rubber vulcanization and porosity. influence and improve the molding quality of sponge rubber; at the same time, due to the high content of styrene in its composition, the sponge rubber has good wear resistance, aging resistance, flex resistance and wear resistance, and still has a high hardness Good flexibility, and its excellent rheological properties can be beneficial to the processing, suitable for the production of shoe m...

Embodiment 2

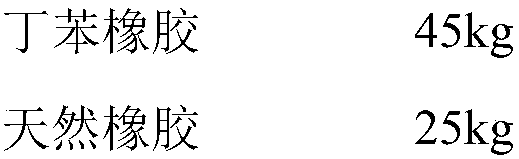

[0047] A cold-resistant microporous sponge rubber, comprising the following components by weight:

[0048]

[0049] Among them, styrene-butadiene rubber is HSR (high styrene rubber) with a styrene content of 60%. HSR is a special variety in styrene-butadiene rubber. Obtained by extrusion dehydration and drying, it is white rubber particles that are easily bonded to each other. It is non-toxic, odorless, has the characteristics of low impurity content and stable quality, and reduces the adverse effects caused by impurities in the process of rubber vulcanization and porosity. influence and improve the molding quality of sponge rubber; at the same time, due to the high content of styrene in its composition, the sponge rubber has good wear resistance, aging resistance, flex resistance and wear resistance, and still has a high hardness Good flexibility, and its excellent rheological properties can be beneficial to the processing, suitable for the production of shoe materials, an...

Embodiment 3

[0061] A cold-resistant microporous sponge rubber, comprising the following components by weight:

[0062]

[0063]

[0064] Among them, styrene-butadiene rubber is HSR (high styrene rubber) with a styrene content of 65%. HSR is a special variety in styrene-butadiene rubber. Obtained by extrusion dehydration and drying, it is white rubber particles that are easily bonded to each other. It is non-toxic, odorless, has the characteristics of low impurity content and stable quality, and reduces the adverse effects caused by impurities in the process of rubber vulcanization and porosity. influence and improve the molding quality of sponge rubber; at the same time, due to the high content of styrene in its composition, the sponge rubber has good wear resistance, aging resistance, flex resistance and wear resistance, and still has a high hardness Good flexibility, and its excellent rheological properties can be beneficial to the processing, suitable for the production of shoe m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com