High-solid-content graphene wave-adsorbing coating and preparation thereof

A wave-absorbing coating with high solid content technology, which is applied to radiation-absorbing coatings, epoxy resin coatings, coatings, etc., can solve the problem of affecting the microwave-absorbing effect of the entire broadband band, the flexibility cannot meet the requirements, and the mechanical properties of the coating are poor. and other problems, to achieve the effect of obvious viscosity reduction, good toughening effect and improved construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

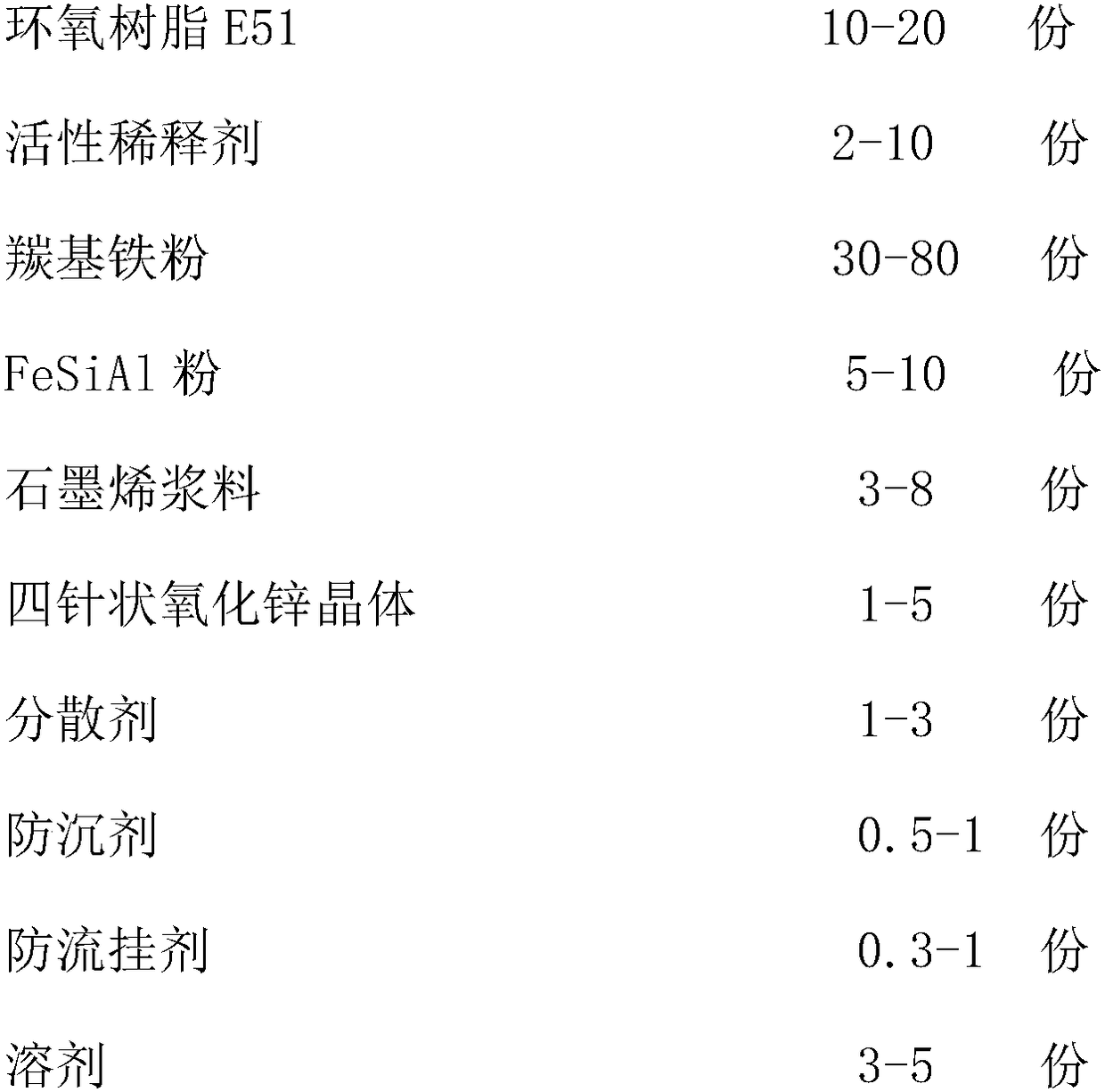

[0047] A component parts by weight

[0048]

[0049] The composition of graphene slurry parts by weight is:

[0050]

[0051] B component parts by weight

[0052] Polyamide curing agent 45 parts

[0053] Phenalkamine curing agent 45 parts

[0054] Solvent 10 parts

[0055] Specific process:

[0056] (1) Preparation of component A:

[0057] ①Preparation of graphene slurry: add graphene, dispersant, auxiliary dispersant and solvent according to the ratio, mix evenly, grind with a ball mill for 20 minutes, and then disperse with ultrasonic waves for 60 minutes to obtain graphene slurry.

[0058] ② Add E51 resin, epoxy toughening diluent, solvent, dispersant, anti-settling agent, anti-sagging agent, carbonyl iron powder, FeSiAl, special zinc oxide crystal and other powder materials, stir well and then sand mill.

[0059] ③Before sanding, observe the viscosity of the slurry, if the viscosity is too high, add epoxy toughening diluent.

[0060] ④Sand grinding to a finene...

Embodiment 2

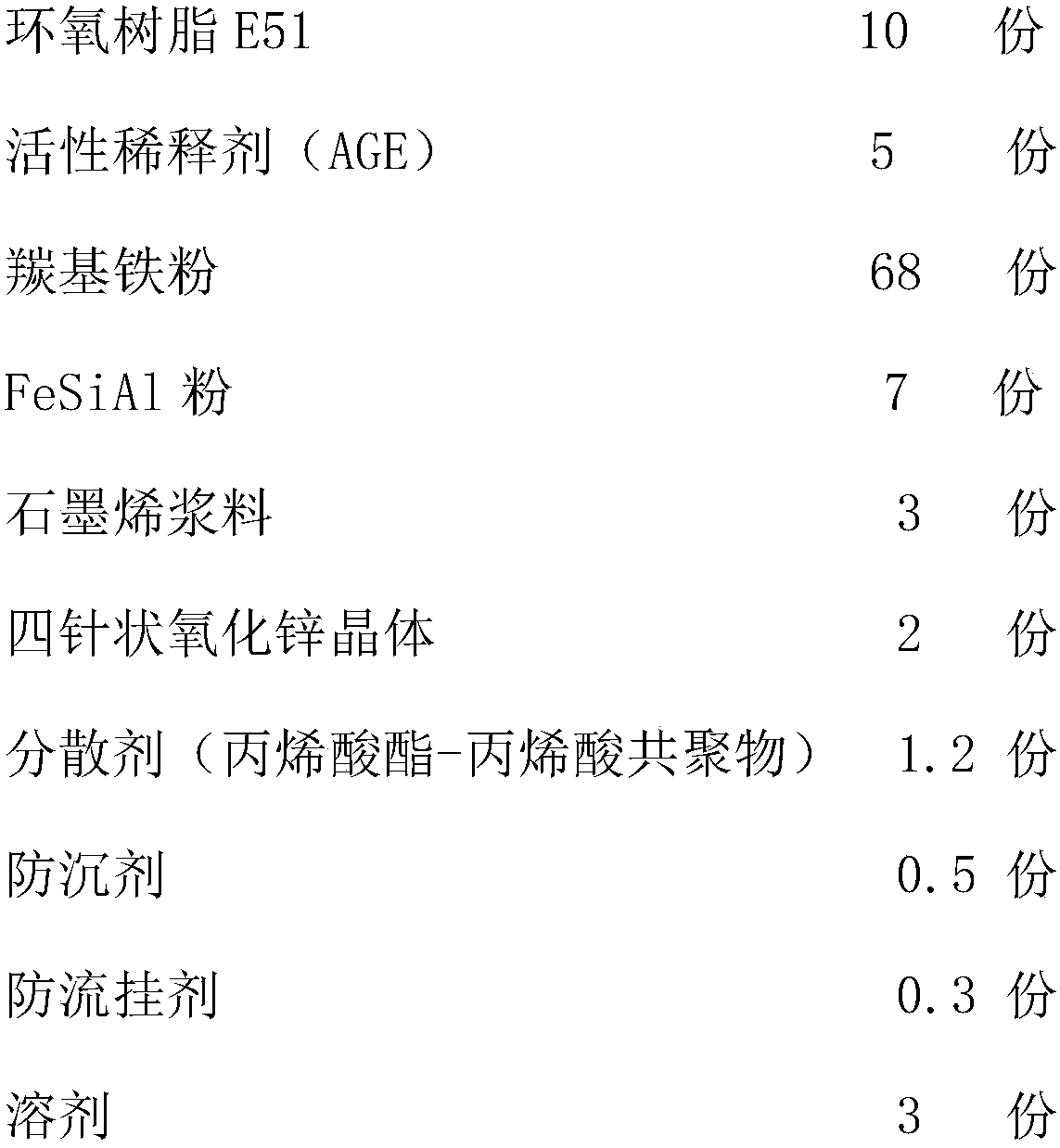

[0066] A component parts by weight

[0067]

[0068]

[0069] The composition of graphene slurry parts by weight is:

[0070]

[0071] B component parts by weight

[0072] Polyamide curing agent 45 parts

[0073] Phenalkamine curing agent 45 parts

[0074] Solvent 10 parts

[0075] The preparation technology of A component and B component is the same as embodiment 1:

[0076] Mix evenly according to the weight ratio of A:B=7:1 to get high-solid graphene absorbing coating.

Embodiment 3

[0078] A component parts by weight

[0079]

[0080]

[0081] The composition of graphene slurry parts by weight is:

[0082]

[0083] B component parts by weight

[0084] Polyamide curing agent 45 parts

[0085] Phenalkamine curing agent 45 parts

[0086] Solvent 10 parts

[0087] The preparation technology of A component and B component is the same as embodiment 1:

[0088] Mix evenly according to the weight ratio of A:B=10:1 to get high-solid graphene absorbing coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com