Exhaust pipe heat insulation shield and installation method

A technology for thermal insulation and heat insulation, which is applied to exhaust devices, mufflers, engine components, etc., can solve problems such as unsatisfactory thermal insulation effect, easy scratches on the surface of the heat insulation cover, and unsightly overall appearance. , to achieve the effect of ensuring thermal insulation effect, saving process steps and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

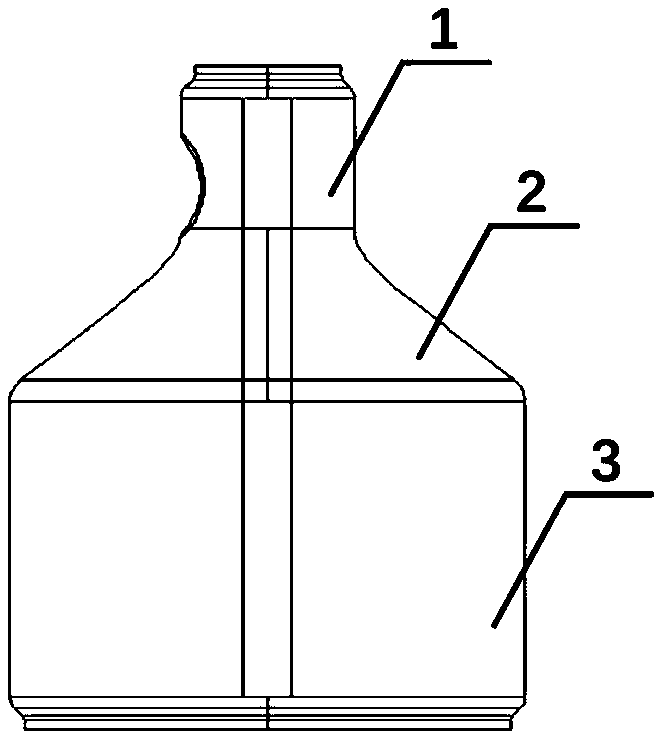

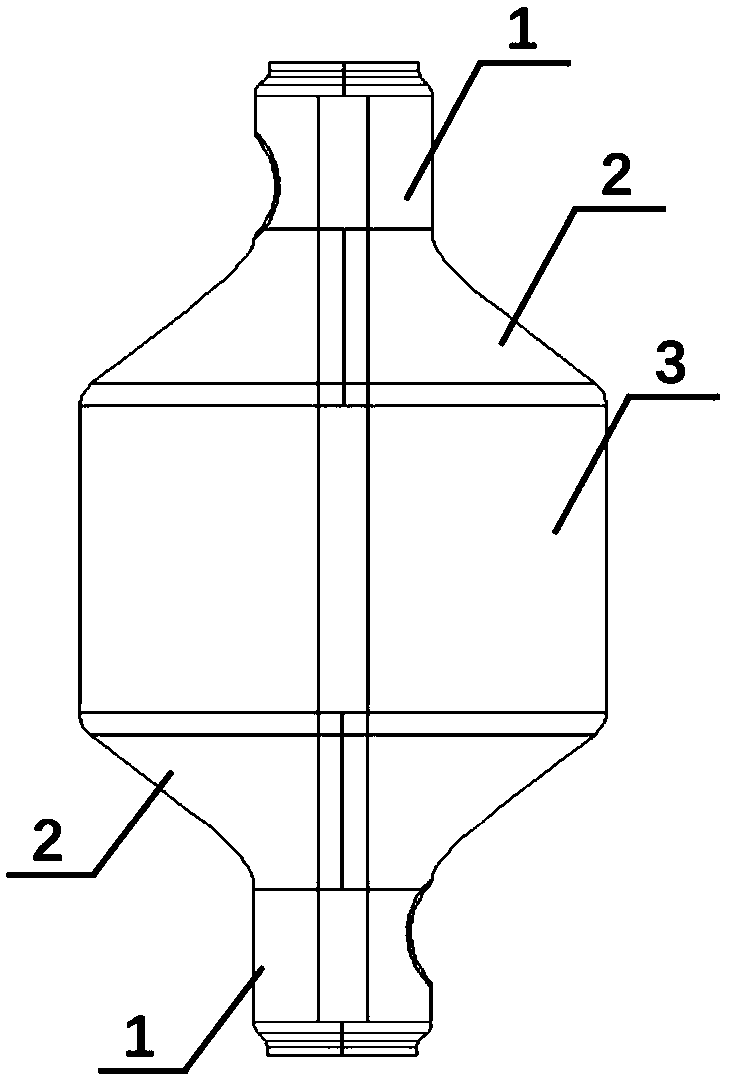

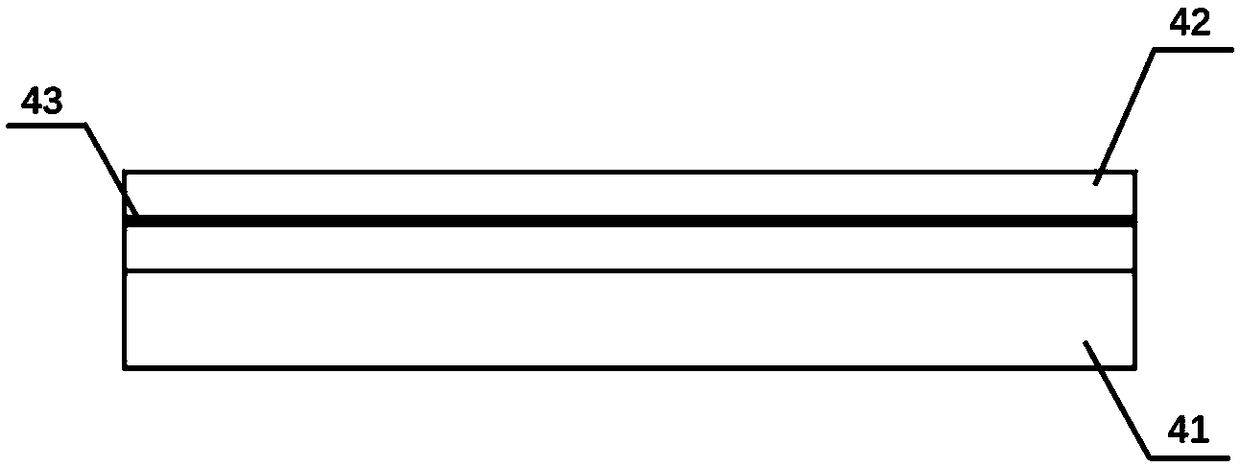

[0040] Such as figure 1 , 3 The present invention discloses a thermal insulation cover for an exhaust pipe, which includes a first heat shield 1 , a second heat shield 2 and a third heat shield 3 . The first heat shield 1 , the second heat shield 2 , and the third heat shield 3 are all composed of a metal shell 41 and a thermal insulation layer 42 . The thermal insulation layer 42 is bonded and fixed on the surface of the metal shell 41, which can ensure the bonding force between the thermal insulation layer 42 and the metal shell 41, and prevent the thermal insulation layer 42 from falling off during use, which affects the thermal insulation effect. The thermal insulation cover is wrapped on the outside of the exhaust pipe during use, and the thermal insulation layer 42 is in contact with the surface of the exhaust pipe to play the role of thermal insulation.

[0041] The first heat shield 1 is wrapped on the exhaust pipe in a cylindrical shape, and the diameter of the bott...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 lies in that the thickness of the metal shell 41 is 0.1 mm, and the thickness of the heat insulating layer 42 is 5 mm. The diameter of the bottom surface of the cylinder formed by the first heat shield 1 wrapping on the exhaust pipe is 50 mm; the diameter of the upper bottom surface of the round platform formed by the second heat shield 2 wrapped on the exhaust pipe is 50 mm, and the diameter of the lower bottom surface is 50 mm. 100mm; the third heat shield 3 is wrapped on the exhaust pipe and has a cylindrical bottom diameter of 100mm.

[0052] Exhaust pipes of different sizes need to correspond to different sizes of heat insulation covers for exhaust pipes. In order to meet the heat insulation performance and ensure the strength of the heat insulation cover, the thickness of the metal shell 41 and the thickness of the heat insulation layer 42 are required. The thickness is also different.

[0053] In addition, ...

Embodiment 3

[0055] The difference between this embodiment and Embodiment 2 lies in that the thickness of the metal shell 41 is 0.2 mm, and the thickness of the heat insulating layer 42 is 10 mm. The diameter of the bottom surface of the cylinder formed by the first heat shield 1 wrapping on the exhaust pipe is 100 mm; the diameter of the upper bottom surface of the round platform formed by the second heat shield 2 wrapped on the exhaust pipe is 100 mm, and the diameter of the lower bottom surface is 100 mm. It is 250mm; the diameter of the bottom surface of the cylinder that is wrapped on the exhaust pipe by the third heat shield 3 is 250mm. The width of the welding zone at both ends of the first heat shield 1 , the second heat shield 2 and the third heat shield 3 is 5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com