A self-cleaning perovskite solar cell and a preparation method thereof

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of hot spot effect, reduce the power generation efficiency of solar cells, reduce the transmittance, etc., to improve the light absorption rate, improve the Photoelectric conversion efficiency, the effect of reducing the probability of hot spot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

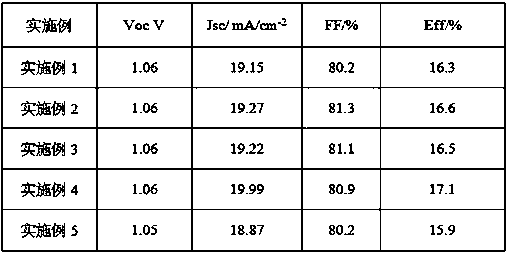

Examples

Embodiment 1

[0038] A perovskite solar cell comprising sequentially transparent flexible organic or glass substrates 1, TiO 2 Self-cleaning layer, 2. Flexible organic or glass substrate, 3. Front electrode, 4. Hole transport layer, 5. Perovskite absorber layer, 6. Electron transport layer, 7. Buffer layer, 8. Metal electrode, 9 , film, 10, backplane. Its concrete preparation steps are as follows:

[0039] A. Treatment of conductive substrate: flexible organic substrate (PEI, PEN, PET, PI flexible plexiglass) or ordinary glass substrate is used as the substrate, and the square resistance of the front electrode layer (FTO or ITO) is 5-40Ω. The pass rate is 75-90%. Conductive substrate cleaning glass cleaner solution ultrasonic cleaning 10-30min, cleaning ultrasonic cleaning twice, 10-30min each time, ethanol cleaning twice, 10-30min each time, acetone ultrasonic cleaning 10-30min, nitrogen blow dry;

[0040] B.TiO 2 Layer preparation: Add 5mL acetylacetone and 10mL butyl titanate dropwis...

Embodiment 2

[0048] A perovskite solar cell comprising sequentially transparent flexible organic or glass substrates 1, TiO 2 Self-cleaning layer, 2. Flexible organic or glass substrate, 3. Front electrode, 4. Hole transport layer, 5. Perovskite absorber layer, 6. Electron transport layer, 7. Buffer layer, 8. Metal electrode, 9 , film, 10, backplane. Its concrete preparation steps are as follows:

[0049] A. Treatment of conductive substrates: flexible organic substrates (PEI, PEN, PET, PI flexible glass) or ordinary glass substrates are used as substrates, and the square resistance of the front electrode layer (FTO or ITO) is 5-40Ω. The rate is 75-90%. Conductive substrate cleaning glass cleaner solution ultrasonic cleaning 10-30min, cleaning ultrasonic cleaning twice, 10-30min each time, ethanol cleaning twice, 10-30min each time, acetone ultrasonic cleaning 10-30min, nitrogen blow dry;

[0050] B.TiO 2 Layer preparation: 5mL acetylacetone and 10mL butyl titanate were added dropwise ...

Embodiment 3

[0058] A perovskite solar cell comprising sequentially transparent flexible or glass substrates 1, TiO 2 Self-cleaning layer, 2. Flexible organic or glass substrate, 3. Front electrode, 4. Hole transport layer, 5. Perovskite absorber layer, 6. Electron transport layer, 7. Buffer layer, 8. Metal electrode, 9 , film, 10, backboard. Its concrete preparation steps are as follows:

[0059] A. Treatment of conductive substrates: flexible organic substrates (PEI, PEN, PET, PI flexible glass) or ordinary glass substrates are used as substrates, and the square resistance of the front electrode layer (FTO or ITO) is 5-40Ω. The rate is 75-90%. Conductive substrate cleaning glass cleaner solution ultrasonic cleaning 10-30min, cleaning ultrasonic cleaning twice, 10-30min each time, ethanol cleaning twice, 10-30min each time, acetone ultrasonic cleaning 10-30min, nitrogen blow dry;

[0060] B.TiO 2 Layer preparation: 5mL acetylacetone and 10mL butyl titanate were added dropwise to 100mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com