A preparation method of olivine type lithium manganese phosphate lithium ion batteryanode material with high specific energy

A lithium-ion battery, olivine-type technology, applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effects of improving electronic conductivity, improving cycle performance and rate performance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

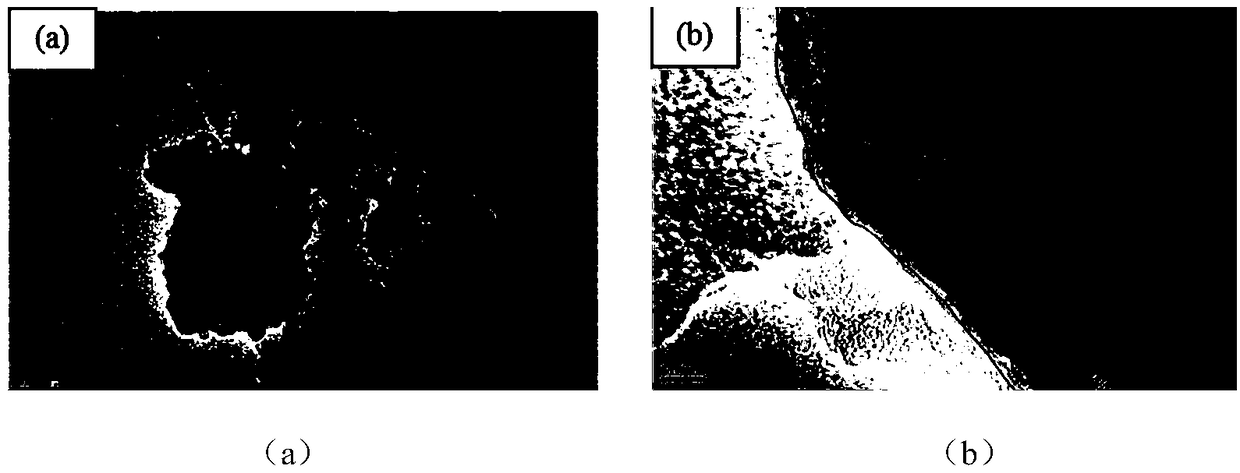

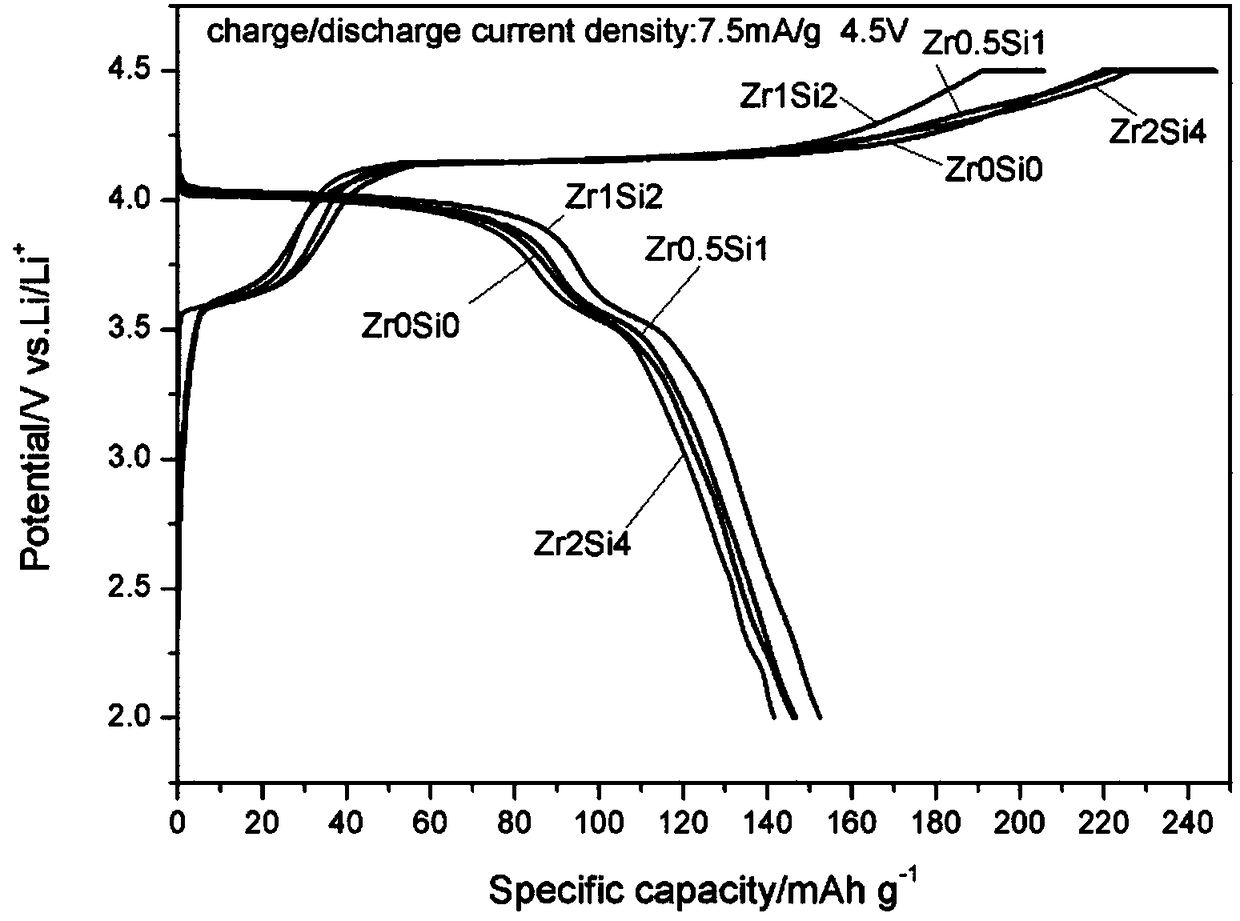

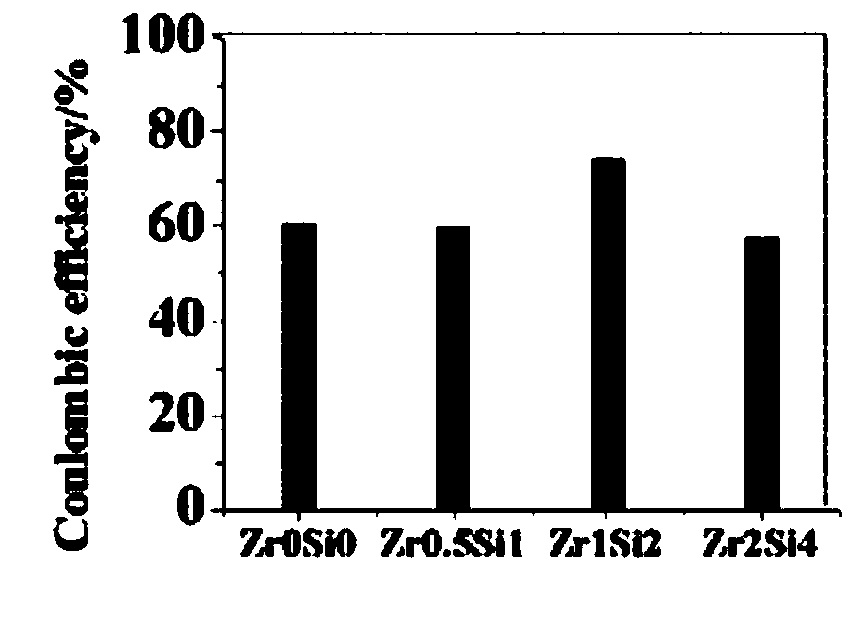

Image

Examples

Embodiment 1

[0035] Press LiMn 0.85-x Fe 0.15 Zr x (PO 4 ) 1-2x (SiO 4 ) 2x Stoichiometric ratio, where x=0.01, mix lithium source, manganese source, phosphorus source, iron source, zirconium source and silicon source evenly, heat treatment at 400°C for 5 hours, then pulverize and grind, and then sinter at 600°C for 10 hours , after sieving, high specific energy olivine manganese phosphate lithium lithium ion battery cathode material powder is obtained.

[0036] Among them, the lithium source is Li 2 CO 3 .

[0037] Manganese source is MnCO 3 .

[0038] Phosphorus source is NH 4 h 2 PO 4 .

[0039] Iron source is FeC 2 o 4 2H 2 O.

[0040] Zirconium source is ZrO 2 .

[0041] Si source is SiO 2 .

Embodiment 2

[0043] Press LiMn 0.85-x Fe 0.15 Zr x (PO 4 ) 1-2x (SiO 4 ) 2x Stoichiometric ratio, where x=0.005, mix lithium source, manganese source, phosphorus source, iron source, zirconium source and silicon source evenly, heat treatment at 300°C for 10 hours, then pulverize and grind, and then sinter at 500°C for 20 hours , after sieving, high specific energy olivine manganese phosphate lithium lithium ion battery cathode material powder is obtained.

[0044] Wherein, the lithium source is LiOH.

[0045] Manganese source is MnO 2 .

[0046] Phosphorus source is NH 4 h 2 PO 4 .

[0047] Iron source is Fe 3 o 4 .

[0048] Zirconium source is Zr(NO 3 ) 2 .

[0049] Si source is H 4 SiO 4 .

Embodiment 3

[0051] Press LiMn 0.85-x Fe 0.15 Zr x (PO 4 ) 1-2x (SiO 4 ) 2x Stoichiometric ratio, where x=0.02, mix lithium source, manganese source, phosphorus source, iron source, zirconium source and silicon source evenly, heat treatment at 350°C for 7 hours, then pulverize and grind, and then sinter at 550°C for 15 hours , after sieving, high specific energy olivine manganese phosphate lithium lithium ion battery cathode material powder is obtained.

[0052] Among them, the lithium source is LiNO 3 .

[0053] Manganese source is Mn 3 o 4 .

[0054] Phosphorus source is (NH 4 ) 2 HPO 4 .

[0055] Iron source is Fe 2 o 3 .

[0056] Zirconium source is ZrO 2 .

[0057] The silicon source is Si(OC 2 h 5 ) 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com