Mixture applied to reactivity coagulating bath and application thereof

A coagulation bath, reactive technology, applied in the field of polymer microporous membranes, can solve the problems of easy phase separation, reduced membrane mechanical properties, easy to agglomerate, etc. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention provides a kind of preparation method of the polymer microporous membrane that utilizes the above-mentioned mixture that is applied to reactive coagulation bath, it comprises the following steps:

[0026] S1, dissolving the polymer in a second organic solvent to obtain a polymer casting solution;

[0027] S2, preparing the casting solution into a flat plate type or a hollow fiber type to form a nascent film;

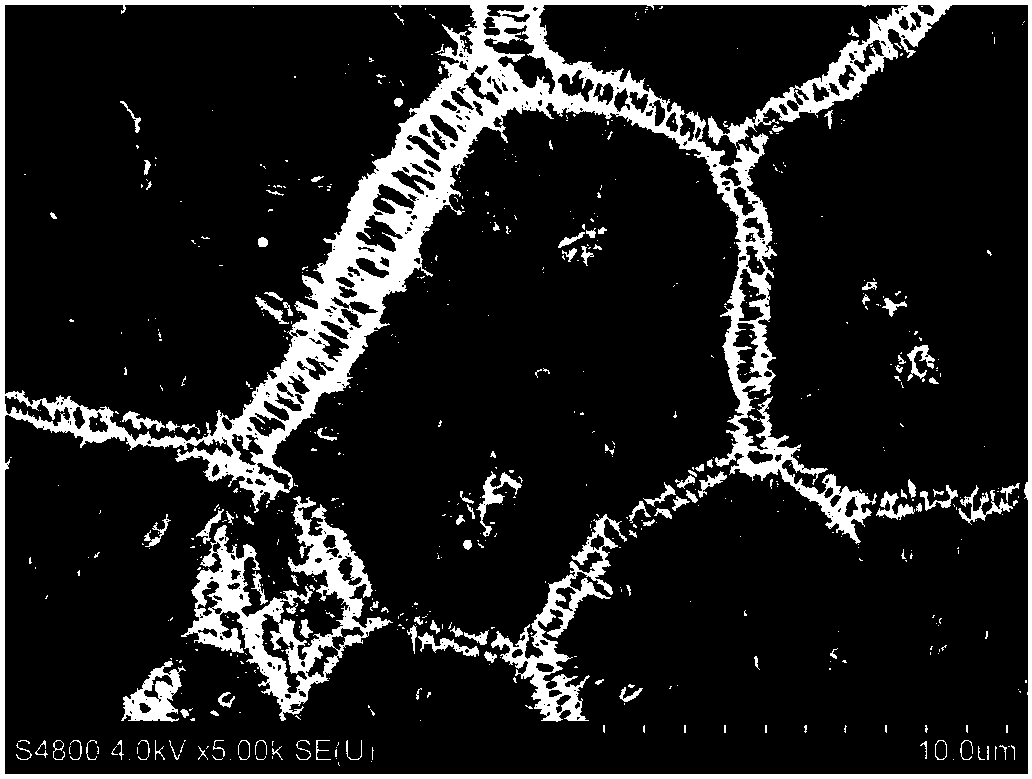

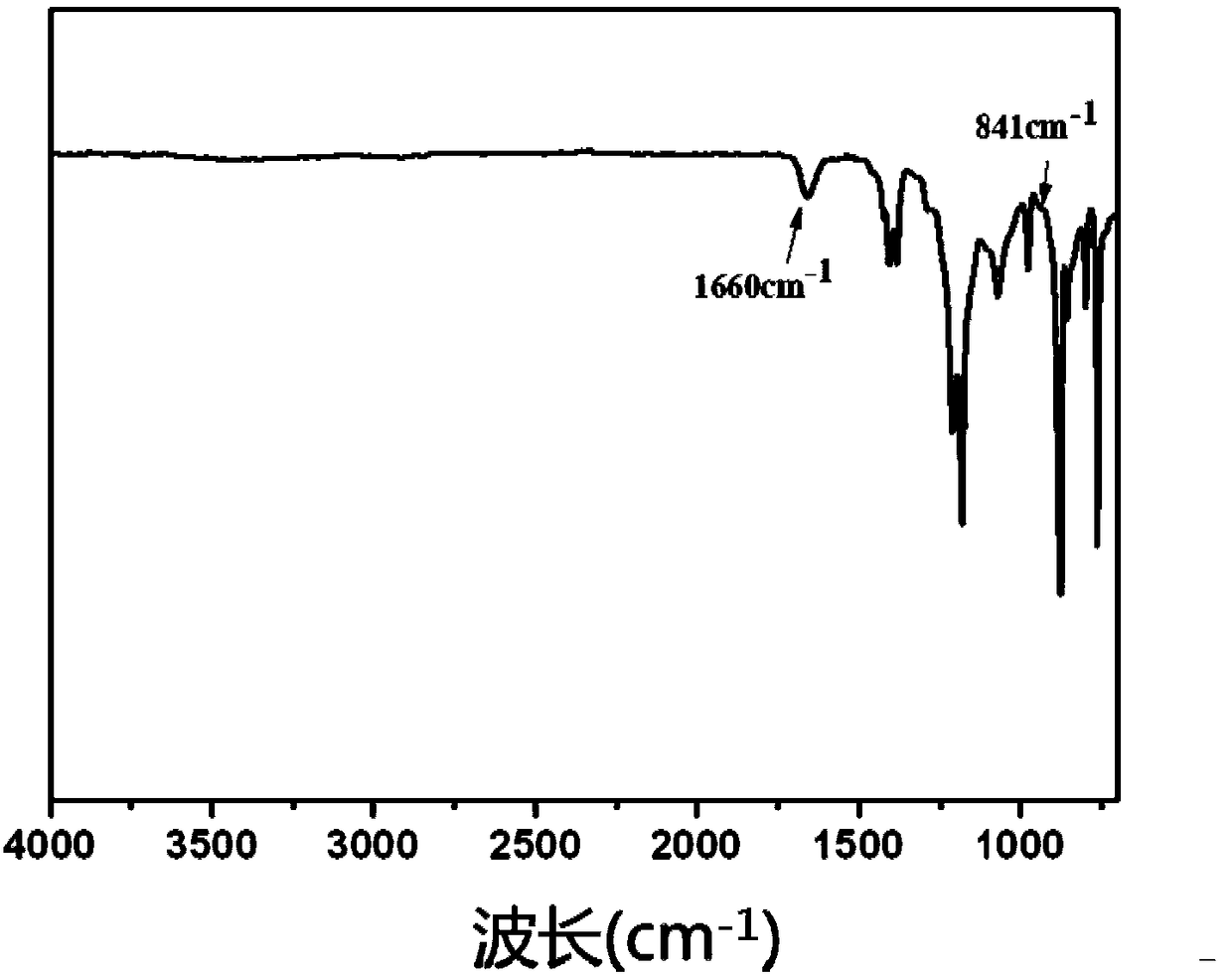

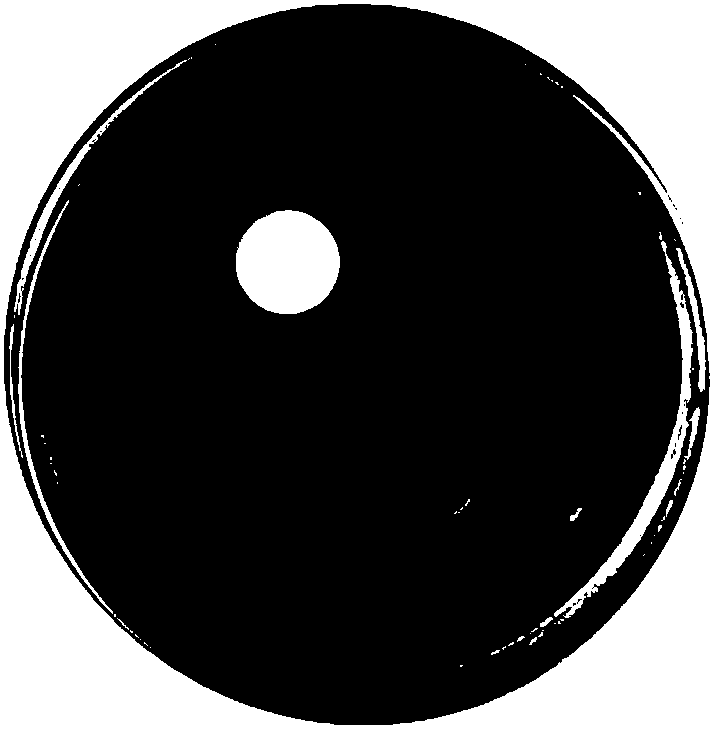

[0028] S3, placing the nascent film in a reactive coagulation bath to solidify to obtain a polymer microporous film, wherein the reactive coagulation bath includes a prepolymer, a first organic solvent and water, and the prepolymer is a functional unit Prepolymers and silane coupling agents are prepared by polymerization under the action of initiators. During the phase separation process, the prepolymers in the reactive coagulation bath migrate to the polymer molecular chains of the nascent film and undergo self-crosslinking to achieve Polym...

Embodiment 1

[0041] Step (1) Dissolve 40 g of N-vinylpyrrolidone and 25 g of vinyltriethoxysilane in 1000 g of triethyl phosphate, and pass nitrogen gas at room temperature for 1 hour to remove dissolved oxygen in the solution. 1 g of azobisisobutyronitrile was quickly added at a stirring speed of 400 r / min, and the temperature was raised to 60° C. After 48 hours of reaction, nitrogen flow was stopped, and the solution was exposed to air to terminate the reaction. The solution obtained from the reaction is sealed and stored for use;

[0042] Step (2) Dissolve 180 grams of polyvinylidene fluoride, 10 grams of polyethylene glycol, and 10 grams of polyvinylpyrrolidone in 800 grams of triethyl phosphate, stir at 70 ° C for 12 hours at a speed of 200 r / min, and vacuumize to remove large Part of the air bubbles, then keep warm at 70 ° C for 12 hours to defoam;

[0043] Step (3) After mixing the solution obtained in step (1) with deionized water at a ratio of 3:7, a reactive coagulation bath is ...

Embodiment 2

[0052] Step (1) Dissolve 10 grams of hydroxymethyl methacrylate, 30 grams of N,N-dimethylaminoethyl methacrylate, 30 grams of vinyltrimethoxysilane and 1000 grams of N,N-dimethylformamide In the process, nitrogen gas was passed at room temperature for 30 hours to remove dissolved oxygen in the solution. 1.5 g of dibenzoyl peroxide was quickly added under stirring at 500 r / min, and the temperature was raised to 80° C. After 40 hours of reaction, the nitrogen flow was stopped, and the solution was exposed to the air to terminate the reaction. The solution obtained from the reaction is sealed and stored for use;

[0053] Step (2) Dissolve 200 grams of polylactic acid, 60 grams of polyoxyethylene-polyoxypropylene-polyoxyethylene, and 10 grams of polyoxyethylene in 730 grams of N,N-dimethylformamide, and stir at 60°C for 18 hours , vacuum to remove most air bubbles. Heat preservation and defoaming at 60°C for 16 hours;

[0054] Step (3) After mixing the solution obtained in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pure water flux | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Pure water flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com