Method for modifying MOFs material through low-temperature plasma and application of MOFs material

A low-temperature plasma and modification technology, applied in the direction of ion exchange, ion exchange regeneration, chemical instruments and methods, etc., can solve the problem of limited organic ligand solubility, thermal stability, chemical stability, functional group compatibility , limited control space for functional modification, narrow range of functional modification, etc., to achieve broad industrial application prospects, prevent channel collapse and damage, and shorten the preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for low temperature plasma modification of MOFs material of the present invention, comprises the following steps:

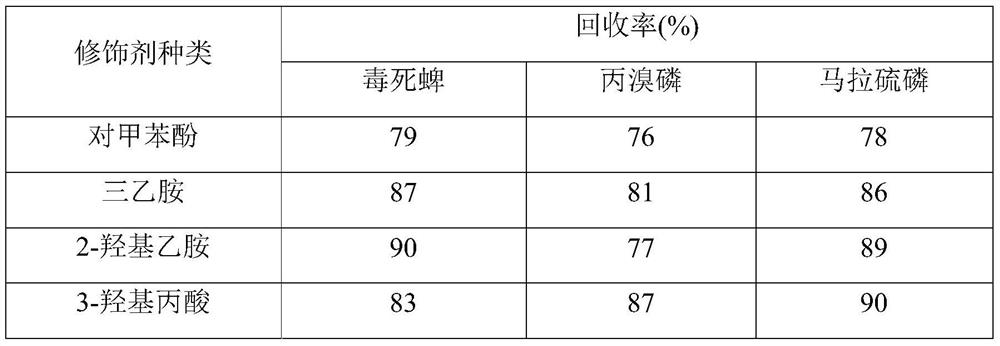

[0031] 0.10g MOFs material is placed in the discharge reaction zone of low-temperature plasma reactor, and MOFs material is specifically UiO-66, and the argon gas that flow rate is 50mL / min passes through the two-necked flask that liquid modifier is housed, and liquid modifier is in An organic reagent that is liquid at room temperature or can be heated to a liquid state by an oil bath with a temperature not higher than 100°C. The specific modifier is shown in Table 1. The argon gas carries the saturated vapor of the modifier into the discharge reaction area of the low-temperature plasma reactor. Start the low-temperature plasma power supply, and carry out the low-temperature plasma discharge reaction at room temperature and normal pressure. The discharge method is dielectric barrier discharge, the discharge power is 1.2W, and the reaction time is 2...

Embodiment 2

[0037] A method for low temperature plasma modification of MOFs material of the present invention, comprises the following steps:

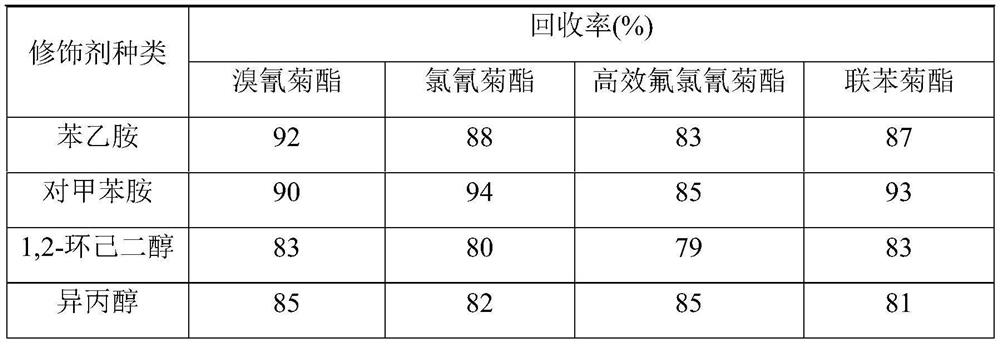

[0038] Put 0.10g MOFs in the discharge reaction zone of the low-temperature plasma reactor. The MOFs are specifically MIL-101, and the argon gas with a flow rate of 50mL / min is passed through a two-necked flask filled with a liquid modifier. The liquid modifier is Liquid organic reagents or organic reagents that can be heated to a liquid state through an oil bath with a temperature not higher than 100°C. See Table 2 for specific modifiers. The argon gas carrying the saturated vapor of the modifier enters the discharge reaction area of the low-temperature plasma reactor, and starts The low-temperature plasma power supply performs low-temperature plasma discharge reaction at room temperature and normal pressure. The discharge method is dielectric barrier discharge, the discharge power is 1.2W, and the reaction time is 20min. The saturated vapor of...

Embodiment 3

[0043] A method for low temperature plasma modification of MOFs material of the present invention, comprises the following steps:

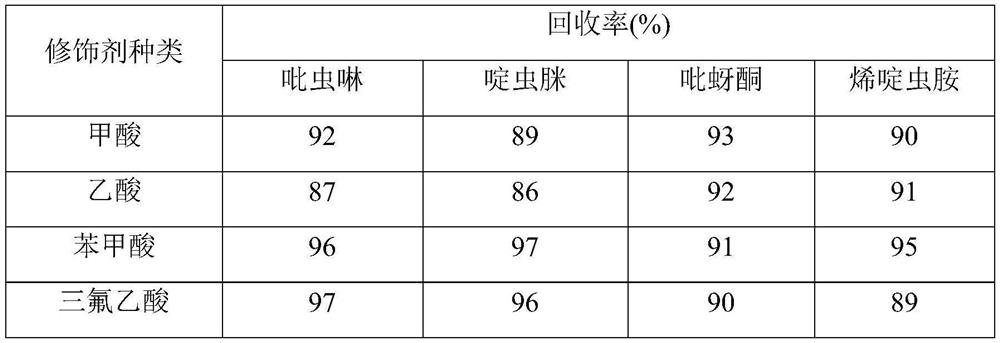

[0044] 0.10g MOFs were placed in the discharge reaction zone of the low-temperature plasma reactor, and the MOFs were specifically ZIF-8. Argon gas with a flow rate of 50mL / min was passed through a two-necked flask filled with a liquid modifier. The liquid modifier was in the form of Liquid organic reagents or organic reagents heated to a liquid state by an oil bath with a temperature not higher than 100°C. The specific modifiers are shown in Table 3. The saturated vapor of the argon gas carrying the modifier enters the discharge reaction area of the low-temperature plasma reactor, and the low-temperature plasma reactor is started. The plasma power supply is used for low-temperature plasma discharge reaction at room temperature and normal pressure. The plasma discharge method is dielectric barrier discharge, the discharge power is 1.2W, and the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com