Functionalized graphene-polyurethane composite microsphere as well as synthesis method and application thereof

A technology of composite microspheres and synthesis methods, which is applied in the field of pollutant adsorption, and can solve problems such as poor adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

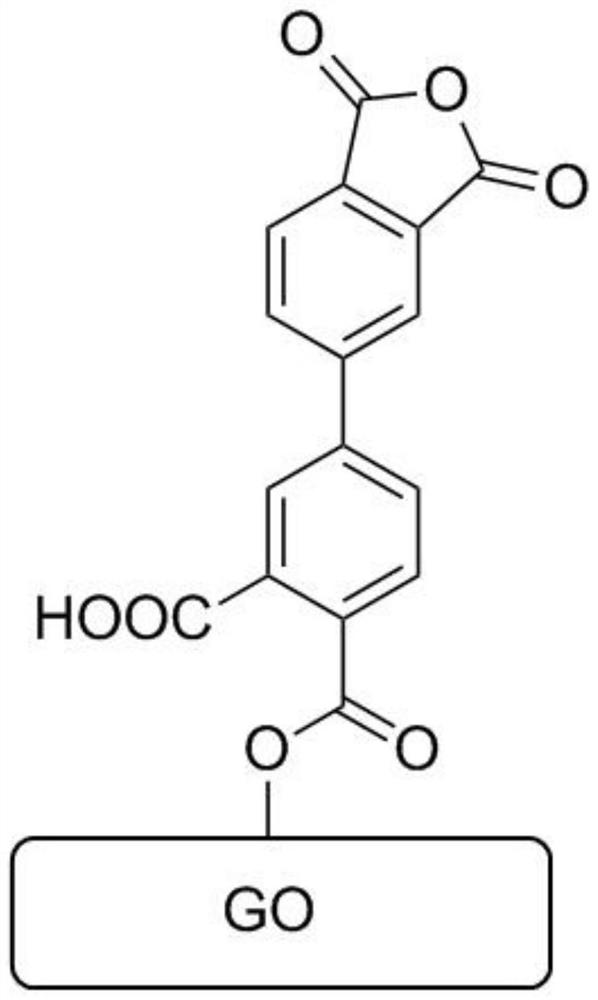

[0031] (1) Add N,N-dimethylacetamide and 100 parts by weight of hydroxylated graphene into the reaction bottle, and add 200 parts of 3,3',4,4'-biphenyl tetra Formic acid dianhydride was reacted at 50° C. for 6 hours in a nitrogen atmosphere, filtered after the reaction, and washed with deionized water and ethanol in sequence to obtain anhydrided graphene.

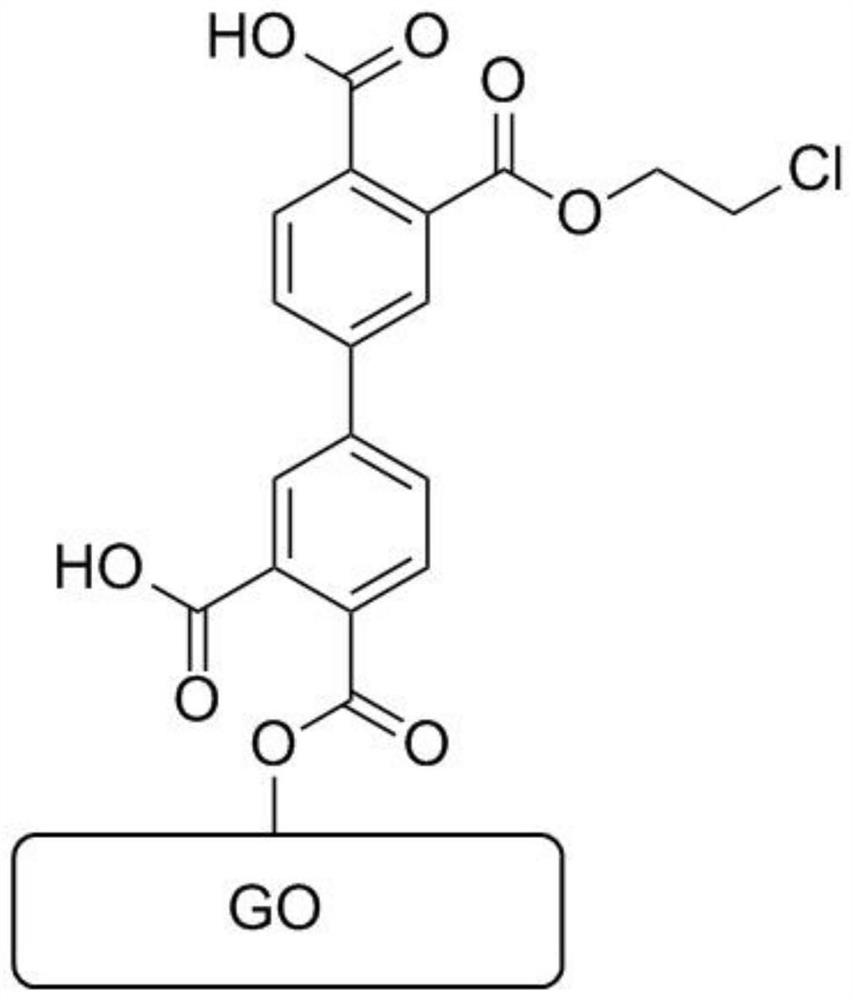

[0032] (2) Add toluene and 100 parts by weight of anhydride-modified graphene to the reaction bottle, disperse evenly, add 120 parts of 2-chloroethanol, heat to 100 ° C, reflux for 5 hours, filter after reaction, and use in turn Wash with ethanol and acetone to obtain chlorinated graphene.

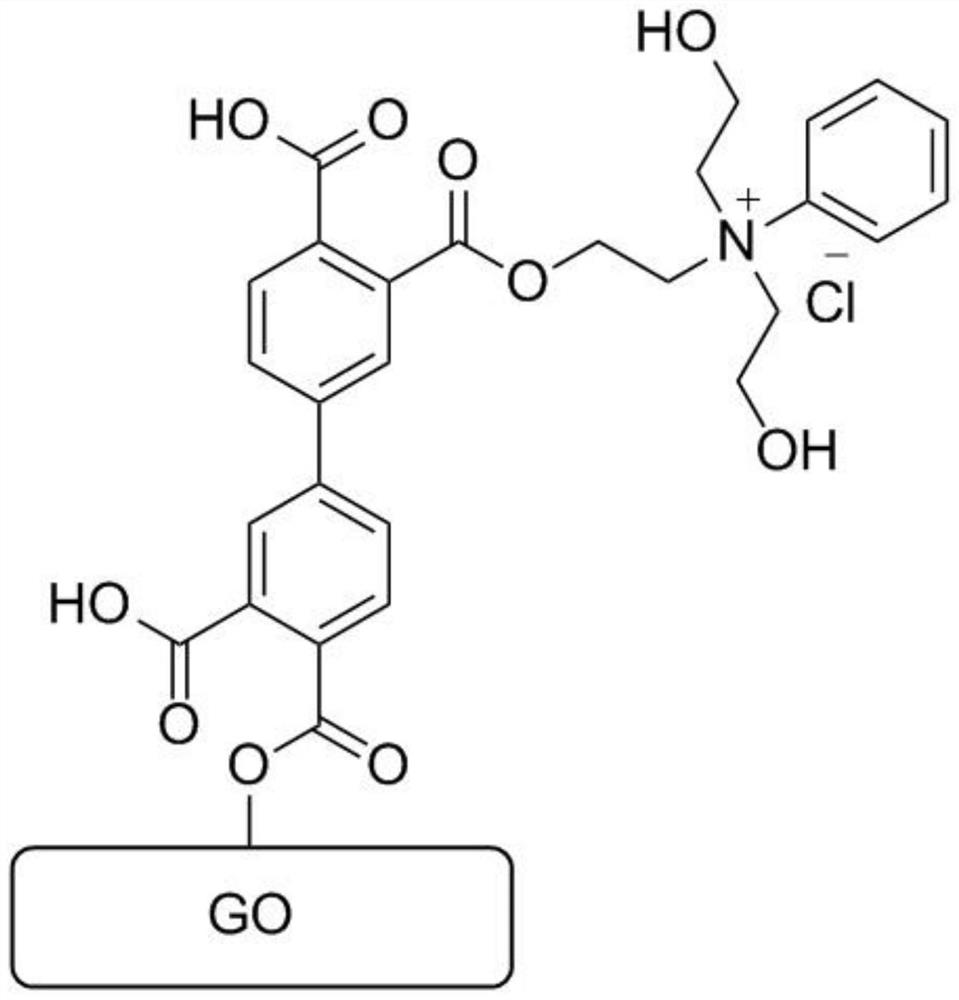

[0033] (3) Add N,N-dimethylformamide, 100 parts by weight of chlorinated graphene and 150 parts of N,N-dihydroxyethylaniline into the reaction bottle, and heat up to 100°C after dispersing evenly The mixture was reacted for 12 hours, and after the reaction, it was filtered and washed with ethanol and acetone in sequence to obtain funct...

Embodiment 2

[0036] (1) Add N,N-dimethylacetamide and 100 parts by weight of hydroxylated graphene into the reaction bottle, and add 300 parts of 3,3',4,4'-biphenyl tetra Formic acid dianhydride was reacted at 60° C. for 12 hours in a nitrogen atmosphere, filtered after the reaction, and washed with deionized water and ethanol in sequence to obtain anhydrided graphene.

[0037] (2) Add toluene and 100 parts by weight of anhydride-modified graphene into the reaction bottle, add 200 parts of 4-chloro-1-butanol after dispersing evenly, heat to 120 ° C, reflux for 15 hours, after the reaction Filter and wash with ethanol and acetone in turn to obtain chlorinated graphene.

[0038] (3) Add N,N-dimethylformamide, 100 parts by weight of chlorinated graphene and 250 parts of N,N-dihydroxyethylaniline into the reaction bottle, and heat up to 140°C after dispersing evenly The mixture was reacted for 12 hours, and after the reaction, it was filtered and washed with ethanol and acetone in sequence to...

Embodiment 3

[0041] (1) Add N,N-dimethylacetamide and 100 parts by weight of hydroxylated graphene into the reaction bottle, and add 400 parts of 3,3',4,4'-biphenyl tetra Formic acid dianhydride was reacted at 60° C. for 12 hours in a nitrogen atmosphere, filtered after the reaction, and washed with deionized water and ethanol in sequence to obtain anhydrided graphene.

[0042] (2) Add toluene and 100 parts by weight of anhydride-modified graphene into the reaction bottle, add 280 parts of 5-chloro-1-pentanol after dispersing evenly, heat to 120 ° C, and reflux for 10 hours. After the reaction Filter and wash with ethanol and acetone in turn to obtain chlorinated graphene.

[0043] (3) Add N,N-dimethylformamide, 100 parts by weight of chlorinated graphene and 320 parts of N,N-dihydroxyethylaniline into the reaction bottle, and heat up to 120°C after dispersing evenly The mixture was reacted for 24 hours. After the reaction, it was filtered and washed with ethanol and acetone in sequence t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com