Preparation method of high-efficiency adsorbent for separating nitrogen and methane

A technology of adsorbent and methane, which is applied in the field of preparation of high-efficiency adsorbents, can solve the problems of unsatisfactory concentration effect, low equilibrium separation coefficient, uneconomical engineering application, etc., and achieves mild preparation conditions, good desorption performance and low preparation cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

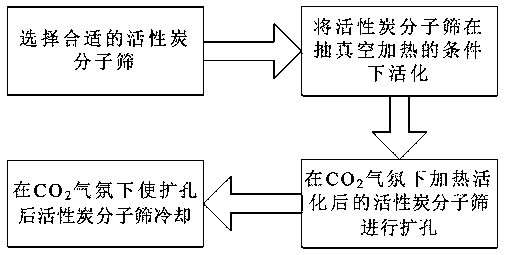

Method used

Image

Examples

Embodiment 1

[0020] Weigh 50.1g of activated carbon molecular sieve, put it in a closed furnace under vacuum conditions, gradually raise the temperature to 120°C, and keep it for 2 hours; gradually introduce CO into the closed furnace 2 Gas, gradually warming up to 250 °C, during which CO is always introduced 2 gas, let CO 2 The gas flows in the furnace, and it can be recycled in industrial production. After heating for 3 hours, stop heating, and the adsorbent is in CO 2 Naturally cooled to room temperature in the atmosphere, samples were taken for testing.

[0021] This adsorbent was packed in a fixed bed adsorber. Fixed bed adsorbers operate at room temperature. Pass 30%CH 4 +70%N 2, the adsorption pressure is 50KPa, after the pressure swing adsorption process, the CH in the product gas 4 The concentration is 85%, and the yield of methane is 72%.

Embodiment 2

[0023] Weigh 70.8g of activated carbon molecular sieve, put it in a closed furnace under vacuum condition, gradually raise the temperature to 150°C, and keep it for 2 hours; gradually introduce CO into the closed furnace 2 Gas, gradually warming up to 250 °C, during which CO is always introduced 2 gas, let CO 2 The gas flows in the furnace and can be recycled in industrial production. After heating for 3 hours, stop heating. Adsorbent in CO 2 Naturally cooled to room temperature in the atmosphere, samples were taken for testing.

[0024] This adsorbent was packed in a fixed bed adsorber. Fixed bed adsorbers operate at room temperature. Pass 30%CH 4 +70%N 2 , the adsorption pressure is 50KPa, after the pressure swing adsorption process, the CH in the product gas 4 The concentration is 88%, and the yield of methane is 71%.

Embodiment 3

[0026] Weigh 58.6g of activated carbon molecular sieve, put it in a closed furnace under vacuum condition, gradually raise the temperature to 150°C, and keep it for 2 hours; gradually introduce CO into the closed furnace 2 Gas, gradually warming up to 280 °C, during which CO is always introduced 2 gas, let CO 2 The gas flows in the furnace and can be recycled in industrial production. After heating for 3 hours, stop heating. Adsorbent in CO 2 Naturally cooled to room temperature in the atmosphere, samples were taken for testing.

[0027] This adsorbent was packed in a fixed bed adsorber. Fixed bed adsorbers operate at room temperature. Pass 30%CH 4 +70%N 2 , the adsorption pressure is 50KPa, after the pressure swing adsorption process, the CH in the product gas 4 The concentration is 92%, and the yield of methane is 68%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com