Preparation method of superfine nano-porous ferronickel oxide electrocatalyst

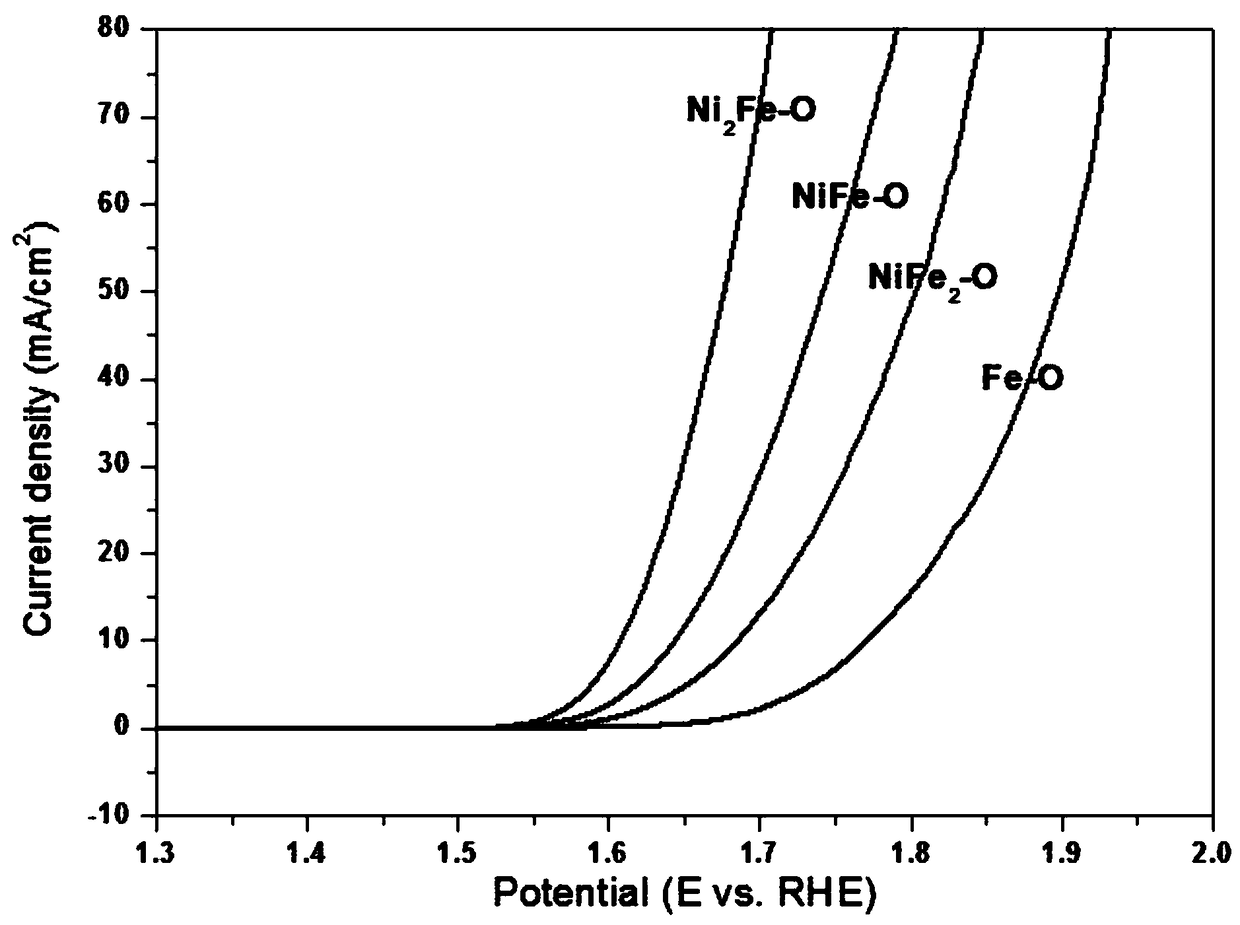

A technology of oxide electricity and ultra-fine nanometers, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of large oxide particles and complex technical processes, etc. problems, to achieve the effect of improved electrocatalytic performance, simple preparation process, and high-efficiency electrocatalytic oxygen production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

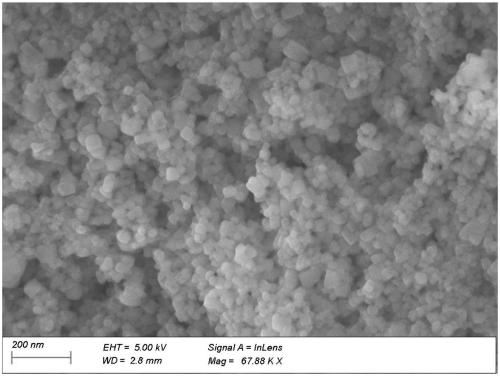

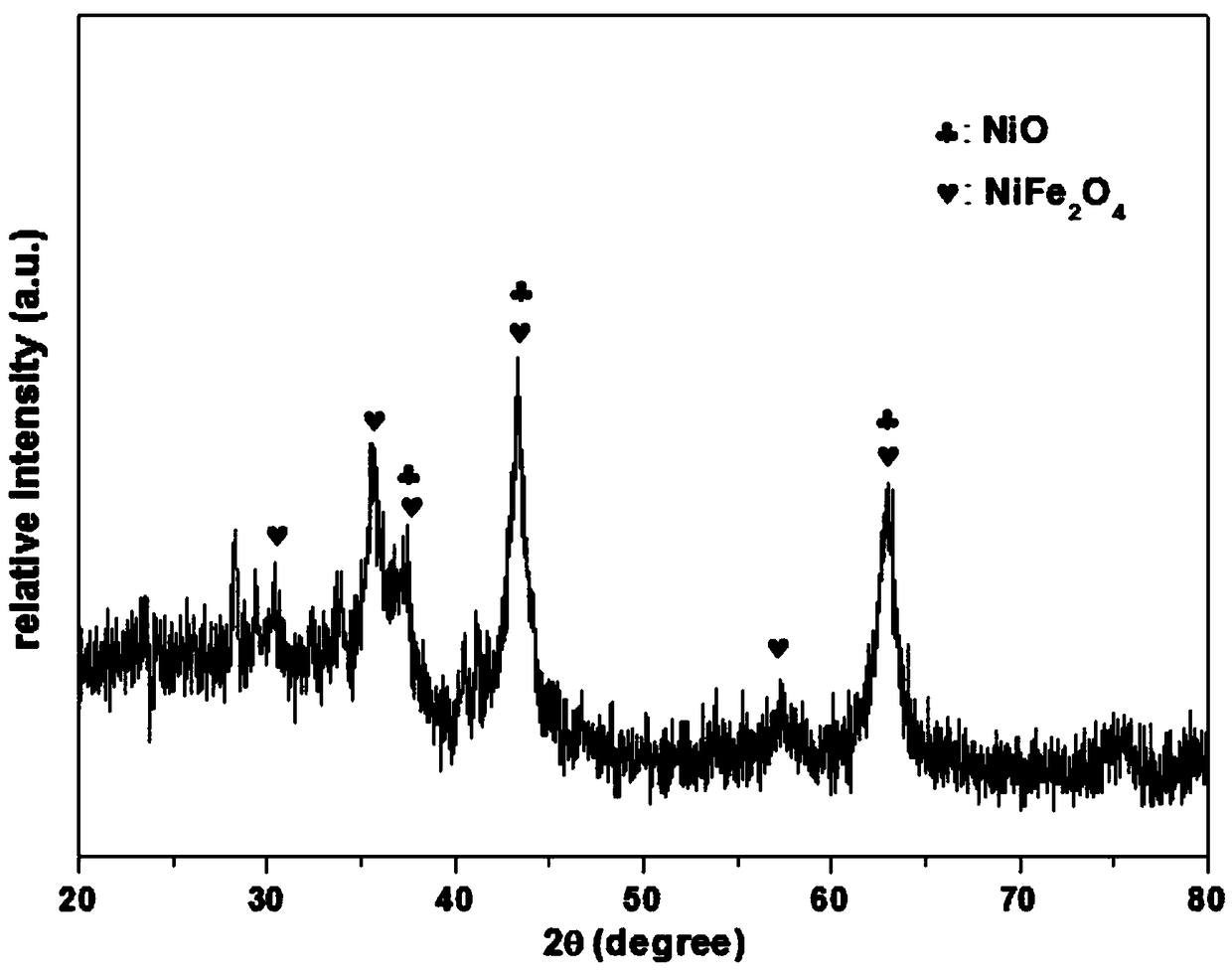

[0025] A method for preparing an ultrafine nanoporous nickel-iron oxide electrocatalyst, comprising the following steps:

[0026] S1), weigh 3g of polyvinylpyrrolidone and add it to 40mL of 0.1mol / L dilute hydrochloric acid, stir until dissolved;

[0027] S2), take by weighing 0.033g nickel acetate tetrahydrate (Ni(CH 3 COO) 2 4H 2 O) and 0.102g of potassium ferrocyanide are added to the mixed solution of step S1), fully stirred evenly;

[0028] S3), put the mixed solution prepared in step S2) into an oven, and keep it warm for 20 hours at a temperature of 80°C;

[0029] S4), the solution in the oven is taken out, centrifuged, washed with water and ethanol for 3 times respectively, the obtained precipitate is put into an oven for drying, and the temperature is set at 80° C., and dried for 24 hours to obtain a nickel-iron ratio of 0.5 Prussian blue (NiFe 2 -PB);

[0030] S5), the class Prussian blue (NiFe 2 -PB) into the muffle furnace, the temperature is set to 500 ° C,...

Embodiment 2

[0033] A method for preparing an ultrafine nanoporous nickel-iron oxide electrocatalyst, comprising the following steps:

[0034] S1), weigh 3g of polyvinylpyrrolidone and add it to 40mL of 0.1mol / L dilute hydrochloric acid, stir until dissolved;

[0035] S2), take by weighing 0.050g nickel acetate tetrahydrate (Ni(CH 3 COO) 2 4H 2 O) and 0.076g potassium ferrocyanide are added to the mixed solution of step S1), fully stirred evenly;

[0036] S3), put the mixed solution prepared in step S2) into an oven, and keep it warm for 20 hours at a temperature of 80°C;

[0037] S4), the solution in the oven is taken out, centrifuged, washed with water and ethanol for 3 times respectively, the obtained precipitate is put into an oven for drying, and the temperature is set at 80° C., and dried for 24 hours to obtain a nickel-iron ratio of 1.0-like Prussian blue NiFe-PB);

[0038] S5), put the Prussian blue-like NiFe-PB) prepared in step S4) into a muffle furnace, set the temperature ...

Embodiment 3

[0041] A method for preparing an ultrafine nanoporous nickel-iron oxide electrocatalyst, comprising the following steps:

[0042] S1), weigh 3g of polyvinylpyrrolidone and add it to 40mL of 0.1mol / L dilute hydrochloric acid, stir until dissolved;

[0043] S2), take by weighing 0.066g nickel acetate tetrahydrate (Ni(CH 3 COO) 2 4H 2 O) and 0.051g of potassium ferrocyanide are added to the mixed solution of step S1), fully stirred evenly;

[0044] S3), put the mixed solution prepared in step S2) into an oven, and keep it warm for 20 hours at a temperature of 80°C;

[0045] S4), the solution in the oven is taken out, centrifuged, washed with water and ethanol for 3 times respectively, the obtained precipitate is put into an oven for drying, and the temperature is set at 80° C., and dried for 24 hours to obtain a nickel-iron ratio of 2.0-like Prussian blue (Ni 2 Fe-PB);

[0046] S5), the class Prussian blue ((Ni 2 Fe-PB) was put into a muffle furnace, the temperature was se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com