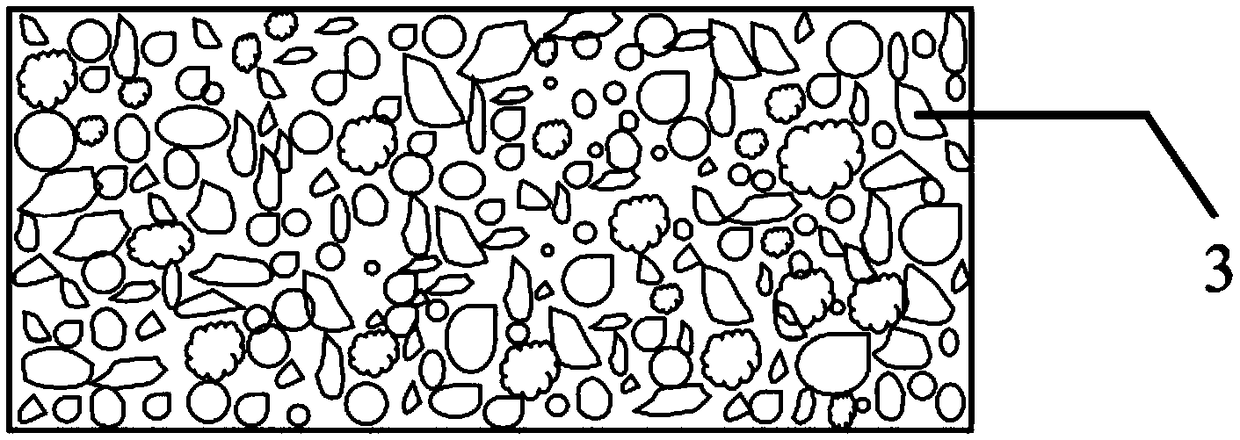

Granite-speckle-imitated ceramic exterior wall brick and preparation method thereof

A technology imitating granite and ceramics, which is applied in the field of building ceramic materials, can solve the problems of difficult application of building exterior wall decoration, poor weather resistance of imitation granite patterns, and inability to achieve graininess, etc., so as to broaden the decorative effect, reduce over-exploitation, and improve The effect of the decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

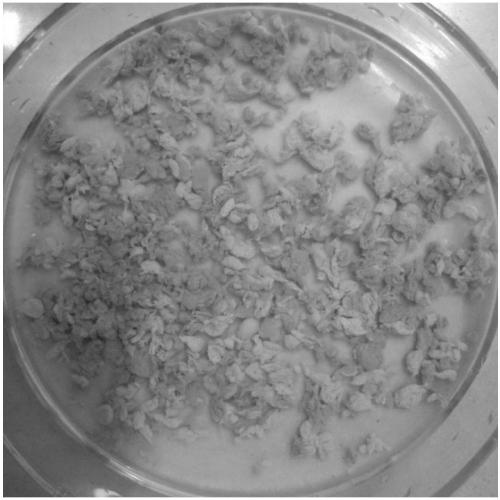

[0042] A preparation method of a ceramic exterior wall tile imitating granite pattern, comprising the following steps:

[0043] (1) Preparation of white particle suspension

[0044] a) Mixing of white granular raw materials: in parts by mass, take 5 parts of anorthite powder, 40 parts of transparent glaze powder, 40 parts of water, 0.1 part of zinc oxide pigment, and 0.2 part of zircon powder, mix the above-mentioned raw materials and ball-mill for 3 hours to The median diameter is 0.69 μm, and a white particle raw material mixture is obtained; during ball milling, the weight ratio of the grinding ball to the raw material in step a) is 3:1, and 0.25 wt % triethanolamine is added as a grinding aid based on the mass percentage of the raw material. agent;

[0045] b) Preparation of gelatinous white slurry: in parts by mass, add Shanghai Sandy SD818-II to the white granular raw material mixture

[0046] 0.1 part of preservative, 0.1 part of Datian Chemical PA-311 defoamer, 2 par...

Embodiment 2

[0063] A preparation method of a ceramic exterior wall tile imitating granite pattern, comprising the following steps:

[0064] (1). Preparation of white particle suspension

[0065] a) Mixing of white granular raw materials: in parts by mass, take 15 parts of anorthite powder, 30 parts of transparent glaze powder, 45 parts of water, 1 part of titanium dioxide pigment, and 0.05 part of zircon powder, mix the above materials and ball-mill for 0.5h to The median diameter is 5.0 μm to obtain a white particle raw material mixture; during ball milling, the weight ratio of the grinding ball to the raw material in step a) is 3:1, and based on the mass fraction of the raw material, 0.25 wt% triethanolamine is added as a grinding aid agent;

[0066] b) Preparation of gelatinous white slurry: in parts by mass, add 0.3 part of DOWICIL QK-20 preservative, 0.3 part of Zhongfu B-315 defoamer, 3 part of CMS thickener to the white granular raw material mixture 2 parts of colloidal magnesium...

Embodiment 3

[0085] A preparation method of a ceramic exterior wall tile imitating granite pattern, comprising the following steps:

[0086] (1) Preparation of white particle suspension

[0087] a) Mixing of white granular raw materials: in parts by mass, take 5 parts of anorthite powder, 30 parts of transparent glaze powder, 60 parts of water, 0.1 part of zinc oxide pigment, and 0.1 part of zircon powder, mix the above materials and ball-mill for 2h to The median diameter is 1.17 μm, and a white particle raw material mixture is obtained; during ball milling, the weight ratio of the grinding ball to the raw material in step a) is 3:1, and based on the mass fraction of the raw material, 0.25 wt% triethanolamine is added as a grinding aid agent;

[0088] b) Preparation of gelatinous white slurry: in parts by mass, add 0.5 part of Delan Chemicals DL-T201 preservative, 0.5 part of BYK-088 defoamer, and HEC thickener to the white granular raw material mixture 5 parts, mixed and stirred at 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com