Self-associating cationic polymer coated humic acid sand-fixing sustained-release agent and preparation method thereof

A cationic polymer and self-association technology, applied in fertilizer mixtures, chemical instruments and methods, and other chemical processes, can solve the problems of no soil improvement and poor sand-fixing effect, and achieve the effect of improving soil and increasing nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

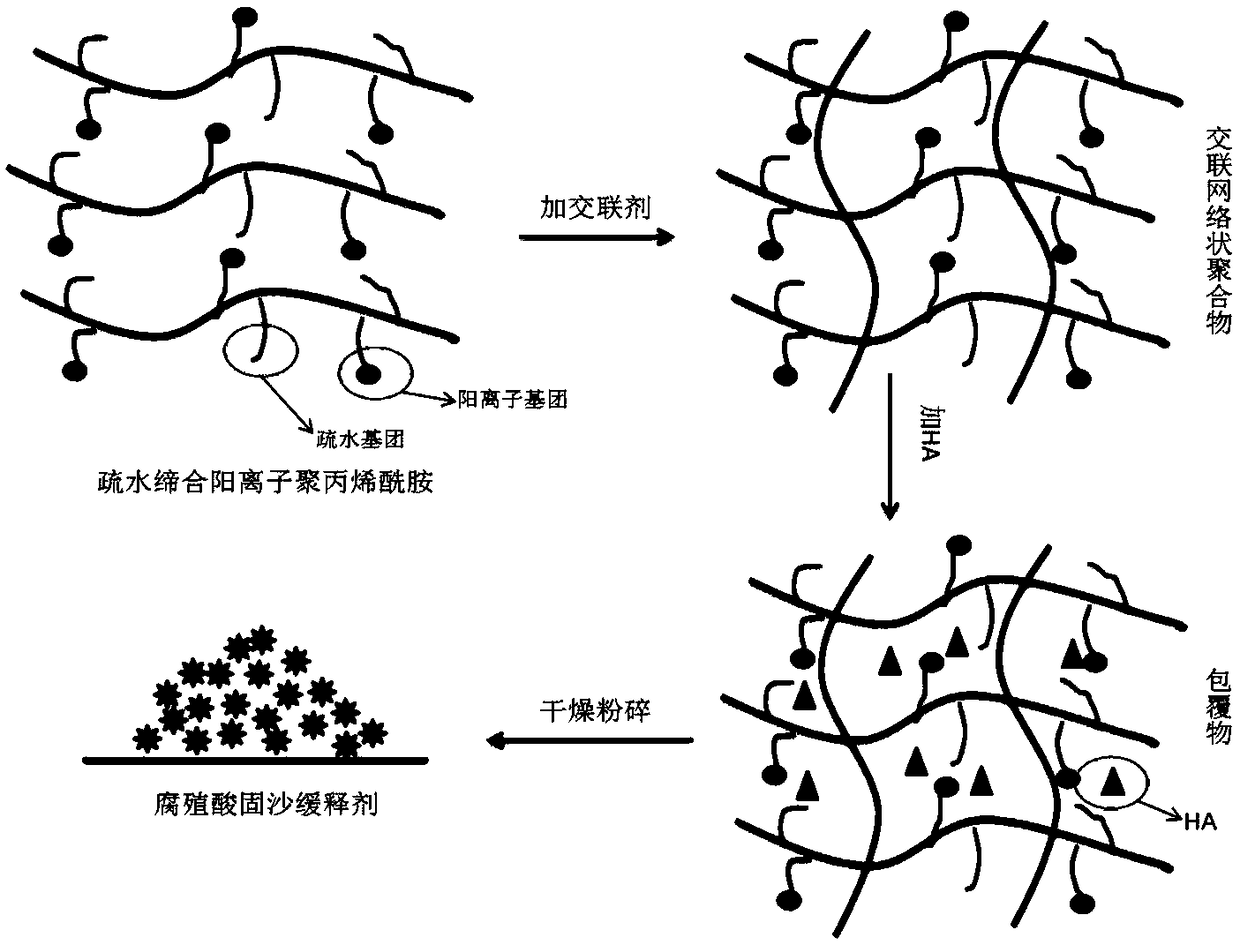

[0038] (1) Dissolving and mixing

[0039] Take 80 parts of deionized water, 8 parts of acrylamide, 1 part of butyl acrylate, and 6 parts of methacryloyloxyethyltrimethylammonium chloride, add them to a three-necked flask, heat in a water bath, blow nitrogen, stir, and heat up to 45°C.

[0040] (2) Polymerization

[0041] After step (1) is fully stirred for 15 minutes, slowly add 0.15 parts of potassium persulfate dissolved in 30 parts of deionized water dropwise, raise the temperature to 65°C, and then dissolve N,N-methylene in 20 parts of deionized water 0.03 parts of bisacrylamide, and stirred to make it fully mixed, and reacted for 8 hours to obtain a cationic polyacrylamide solution with a three-dimensional network structure.

[0042] (3) Coating

[0043] After the above process is completed, 3 parts of potassium humate dissolved in 7 parts of deionized water is added dropwise to make the cationic polyacrylamide coat the humic acid molecules to obtain a coating.

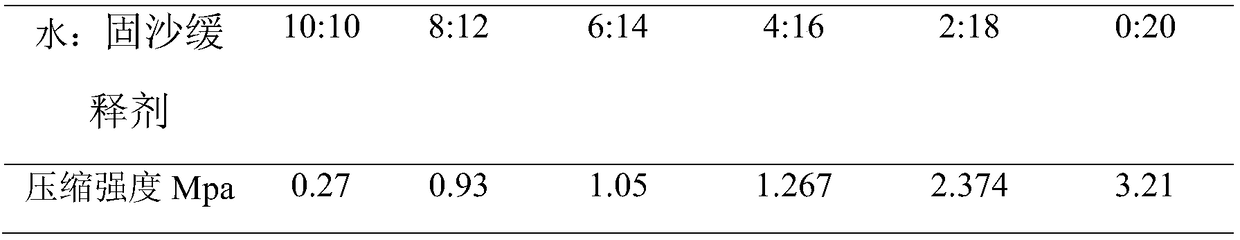

[004...

Embodiment 2

[0047] (1) Dissolving and mixing

[0048] Take 80 parts of deionized water, 10 parts of acrylamide, 1.5 parts of butyl acrylate, and 8 parts of methacryloyloxyethyltrimethylammonium chloride, add them to a three-necked flask, heat in a water bath, blow nitrogen, stir, and heat up to 50°C.

[0049] (2) Polymerization

[0050] After step (1) is fully stirred for 15 minutes, slowly add 0.3 parts of potassium persulfate dissolved in 30 parts of deionized water dropwise, raise the temperature to 60°C, and then dissolve N,N-methylene in 20 parts of deionized water 0.049 parts of bisacrylamide, and stirred to make it fully mixed, and reacted for 9 hours to obtain a cationic polyacrylamide solution with a three-dimensional network structure.

[0051] (3) Coating

[0052] After the above process is completed, 3 parts of potassium humate dissolved in 7 parts of deionized water is added dropwise to it, and the humic acid molecules are coated by cationic polyacrylamide to obtain a coat...

Embodiment 3

[0056] (1) Dissolving and mixing

[0057] Take 80 parts of deionized water, 12 parts of acrylamide, 2 parts of butyl acrylate, and 10 parts of methacryloyloxyethyltrimethylammonium chloride, add them to a three-necked flask, heat in a water bath, blow nitrogen, stir, and heat up to 55°C.

[0058] (2) Polymerization

[0059] After step (1) is fully stirred for 15 minutes, slowly add 0.48 parts of potassium persulfate dissolved in 30 parts of deionized water dropwise, raise the temperature to 55°C, and then dissolve N,N-methylene in 20 parts of deionized water 0.072 parts of bisacrylamide, and stirred to make it fully mixed, and reacted for 10 hours to obtain a cationic polyacrylamide solution with a three-dimensional network structure.

[0060] (3) Coating

[0061] After the above process is completed, 3 parts of potassium humate dissolved in 7 parts of deionized water is added dropwise to it, and the humic acid molecules are coated by cationic polyacrylamide to obtain a coati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com