Special oil-stain cleaning agent for kitchen and preparation method of special oil stain cleaning agent

An oil cleaning agent and kitchen technology, applied in the field of daily chemistry, can solve the problems of poor antibacterial performance and poor stability of kitchen cleaning agents, and achieve low cost, excellent antibacterial and stability, and skin protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

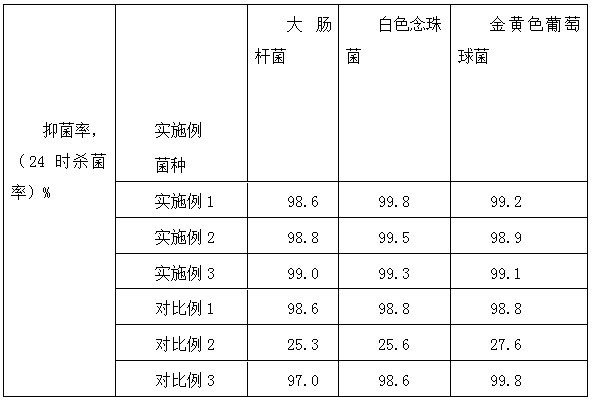

Examples

Embodiment 1

[0029] A special oil cleaning agent for kitchen, comprising the following raw materials in parts by weight: 30 parts of surfactant, 2 parts of antibacterial agent, 5 parts of coconut oil fatty acid diethanolamide, 5 parts of olive oil, 3 parts of attapulgite, methylcyclo 0.5 part of polymer of ethylene oxide, ethylene oxide and mono(2-ethylhexyl) ether, 0.03 part of plant essential oil, 3 parts of glycerin, 0.02 part of pyrethrin, 0.3 part of limonol, 3 parts of aloe mucus , 100 parts of deionized water.

[0030] Wherein, the surfactant is a mixture of sodium α-olefin sulfonate and sodium fatty alcohol polyoxyethylene ether sulfate at a mass ratio of 1:1.25.

[0031] Among them, the antibacterial agent is silver-loaded diatomite. Add the oxide containing silver ions to the diatomite, ultrasonically treat it for 40 minutes, mix well, add deionized water, burn and decompose it at a high temperature of 1500°C for 2 hours, and cool to room temperature , dried and then pulverized ...

Embodiment 2

[0039] A special oil cleaning agent for kitchen, comprising the following raw materials in parts by weight: 30 parts of surfactant, 2 parts of antibacterial agent, 5 parts of coconut oil fatty acid diethanolamide, 5 parts of olive oil, 3 parts of attapulgite, methylcyclo 0.5 part of polymer of ethylene oxide, ethylene oxide and mono(2-ethylhexyl) ether, 0.03 part of plant essential oil, 3 parts of glycerin, 0.02 part of pyrethrin, 0.3 part of limonol, 3 parts of aloe mucus , 100 parts of deionized water.

[0040] Wherein, the surfactant is a mixture of sodium α-olefin sulfonate and sodium fatty alcohol polyoxyethylene ether sulfate at a mass ratio of 1:1.25.

[0041]Among them, the antibacterial agent is silver-loaded diatomite. Add the oxide containing silver ions to the diatomite, ultrasonically treat it for 40 minutes, mix thoroughly, add deionized water, burn and decompose it at a high temperature of 1700°C for 2 hours, and cool to room temperature , dried and then pulver...

Embodiment 3

[0049] A special oil cleaning agent for kitchen, comprising the following raw materials in parts by weight: 30 parts of surfactant, 2 parts of antibacterial agent, 5 parts of coconut oil fatty acid diethanolamide, 5 parts of olive oil, 3 parts of attapulgite, methylcyclo 0.5 part of polymer of ethylene oxide, ethylene oxide and mono(2-ethylhexyl) ether, 0.03 part of plant essential oil, 3 parts of glycerin, 0.02 part of pyrethrin, 0.3 part of limonol, 3 parts of aloe mucus , 100 parts of deionized water.

[0050] Wherein, the surfactant is a mixture of sodium α-olefin sulfonate and sodium fatty alcohol polyoxyethylene ether sulfate at a mass ratio of 1:1.25.

[0051] Among them, the antibacterial agent is silver-loaded diatomite. Add the oxide containing silver ions to the diatomite, ultrasonically treat it for 40 minutes, mix well, add deionized water, burn and decompose it at a high temperature of 1600 ° C for 2 hours, and cool to room temperature , dried and then pulverize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com