Method for synthesizing ZnO supported Fe2O3 nanoheterostructured gas sensor on basis of MOF (metal-organic framework) template

A nano-heterostructure, gas-sensing element technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problem of long response recovery time, high working temperature of gas sensor, low sensitivity, etc. problem, to achieve excellent selectivity and improve the effect of gas sensing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

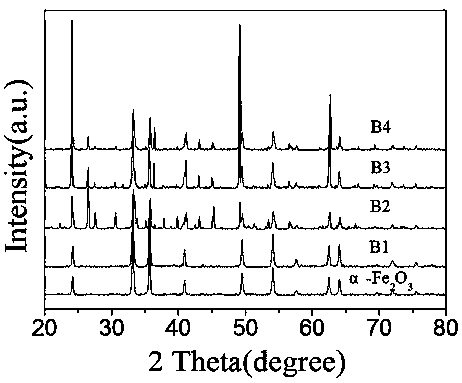

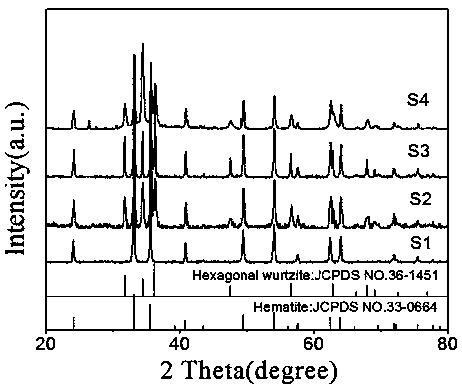

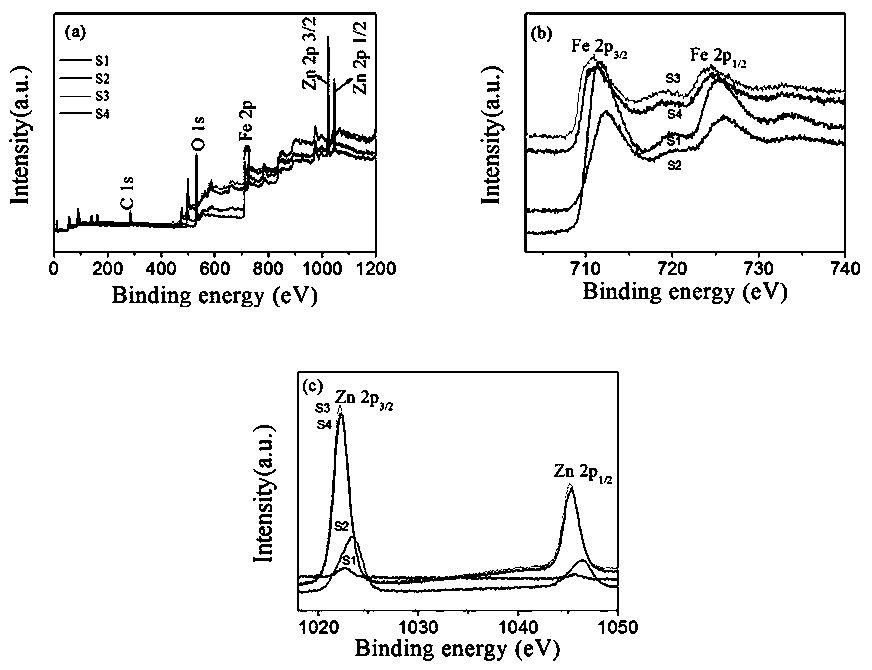

[0024] (1) Weigh 0.116 g of fumaric acid and dissolve in 10 mL of deionized water, stir for 1 h at room temperature, add 0.27 g of ferric chloride hexahydrate, stir for 30 min, and put it in the reactor at 100°C for 12 h; after the reaction is complete After natural cooling to room temperature, wash the precipitate with absolute ethanol and deionized water for 5 times, and finally collect the solid product MIL-88A by centrifugation; after drying, the product is placed in a muffle furnace and calcined at a constant temperature of 500℃ for 2 h, and the heating rate is set Is 1℃ / min, and finally α-Fe is obtained 2 O 3 Nanorod, marked as S5;

[0025] (2) Porous α-Fe prepared in step (1) 2 O 3 Nanorods are used as the substrate and methanol and water are used as a mixed solvent to combine porous α-Fe 2 O 3 The nanorods were immersed in a solution containing zinc acetate and a solution containing fumaric acid successively. The specific process is as follows: Weigh 0.020 g α-Fe 2 O 3 Put...

Embodiment 2

[0029] Repeat the soaking process and solvothermal reaction described in step (2) once for the powder obtained by centrifugation after step (2) solvothermal reaction in Example 1 (that is, the number of soaking and solvothermal reactions is increased to 2), and the remaining steps are the same as the implementation Example 1 is the same; the obtained Zn-MOF / α-Fe 2 O 3 The powder is labeled B2, and the final sample after calcination is labeled S2.

Embodiment 3

[0031] Repeat the soaking process and solvothermal reaction described in step (2) for the powder obtained by centrifugation after step (2) solvothermal reaction in Example 1 (that is, the number of soaking and solvothermal reactions is increased to 3), and the remaining steps are the same as the implementation Same as Example 1; the resulting Zn-MOF / α-Fe 2 O 3 The powder is labeled B3, and the final sample after calcination is labeled S3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com