A high-sensitivity torsional pendulum silicon micro-accelerometer and its preparation method

A high-sensitivity, accelerometer technology, applied in the direction of velocity/acceleration/shock measurement, measurement of acceleration, instruments, etc., can solve the problem of small effective detection area of sensitive mass, limitations of temperature characteristics and robustness, low device space utilization, etc. problems, to achieve the effect of increasing the effective detection area, improving space utilization, and high processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

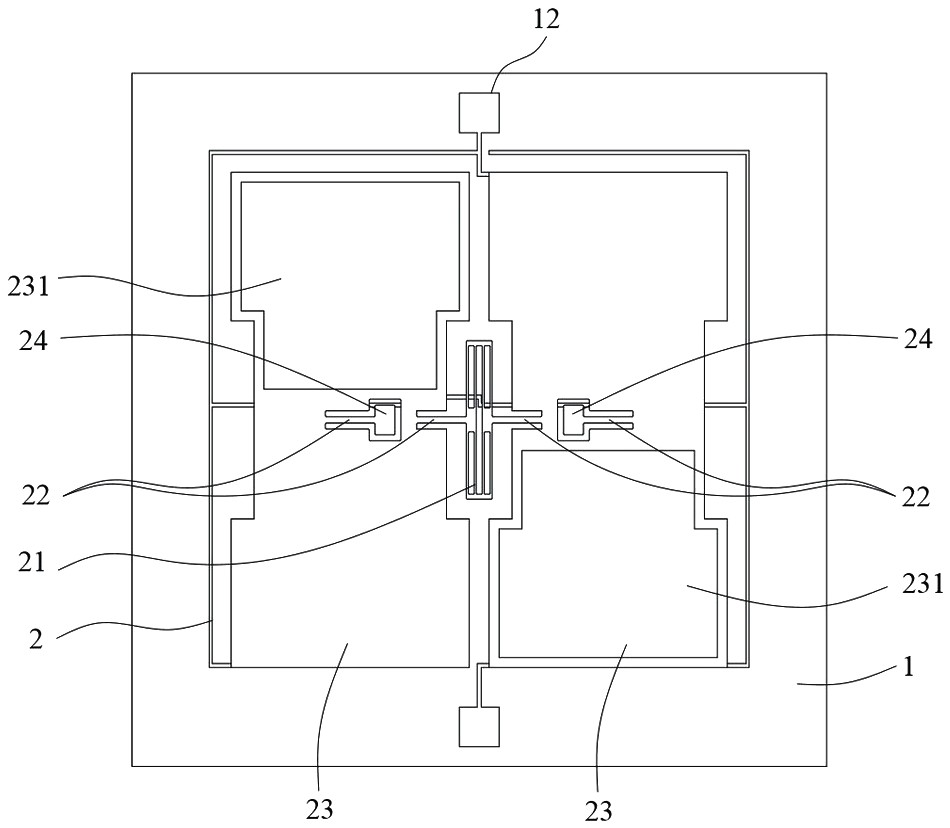

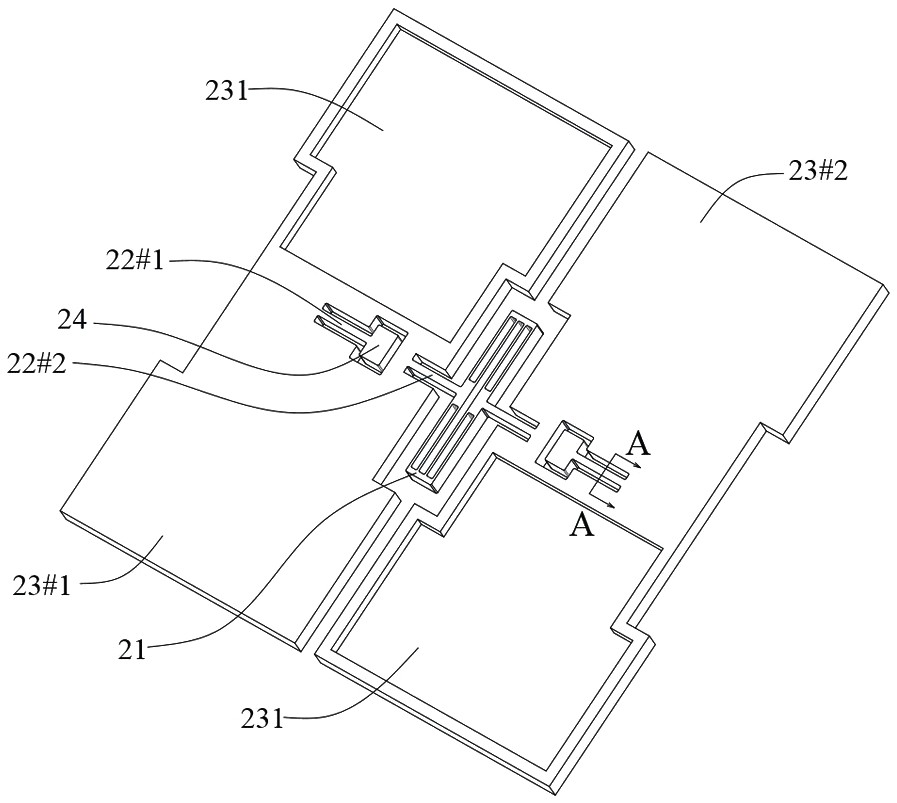

Image

Examples

preparation example Construction

[0062] Such as Image 6 As shown, the implementation steps of the preparation method of the high-sensitivity torsion-type silicon micro-accelerometer of the present embodiment include:

[0063] 1) Prepare the first SOI silicon wafer for preparing the silicon substrate 1, such as Image 6 As shown in (a), the device layer thickness of the first SOI silicon chip in this embodiment is 6 microns;

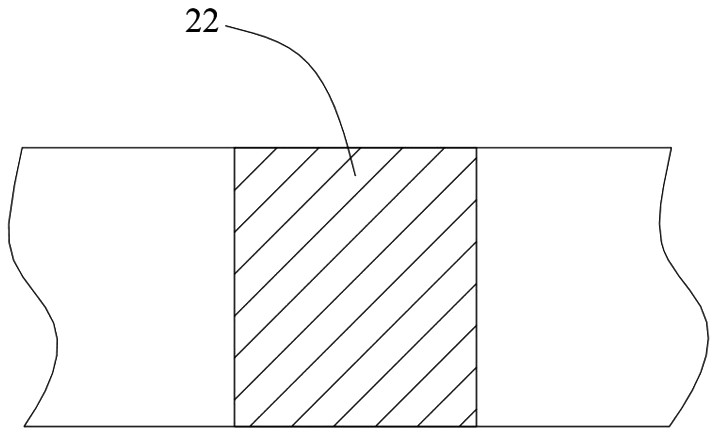

[0064] 2) On the surface of the first SOI silicon wafer, form the capacitance gap between the silicon sensitive structure 2 and the silicon substrate 1 by dry etching the first depth (2 microns), such as Image 6 as shown in (b);

[0065] 3) On the surface of the first piece of SOI silicon wafer, form the capacitor plate assembly 11 and the lead electrode assembly 12 by dry etching the second depth (4 microns), such as Image 6 as shown in (c);

[0066] 4) epitaxially grow a layer of 0.5 micron thick silicon dioxide on the surface of the first SOI silicon wafer, such as Image 6 as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com