An electromagnetic wave connection heating device

A heating device and electromagnetic wave technology, applied in the direction of electric heating device, electric/magnetic/electromagnetic heating, coil device, etc., can solve problems such as poor equipment, high power consumption, and slow technological development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

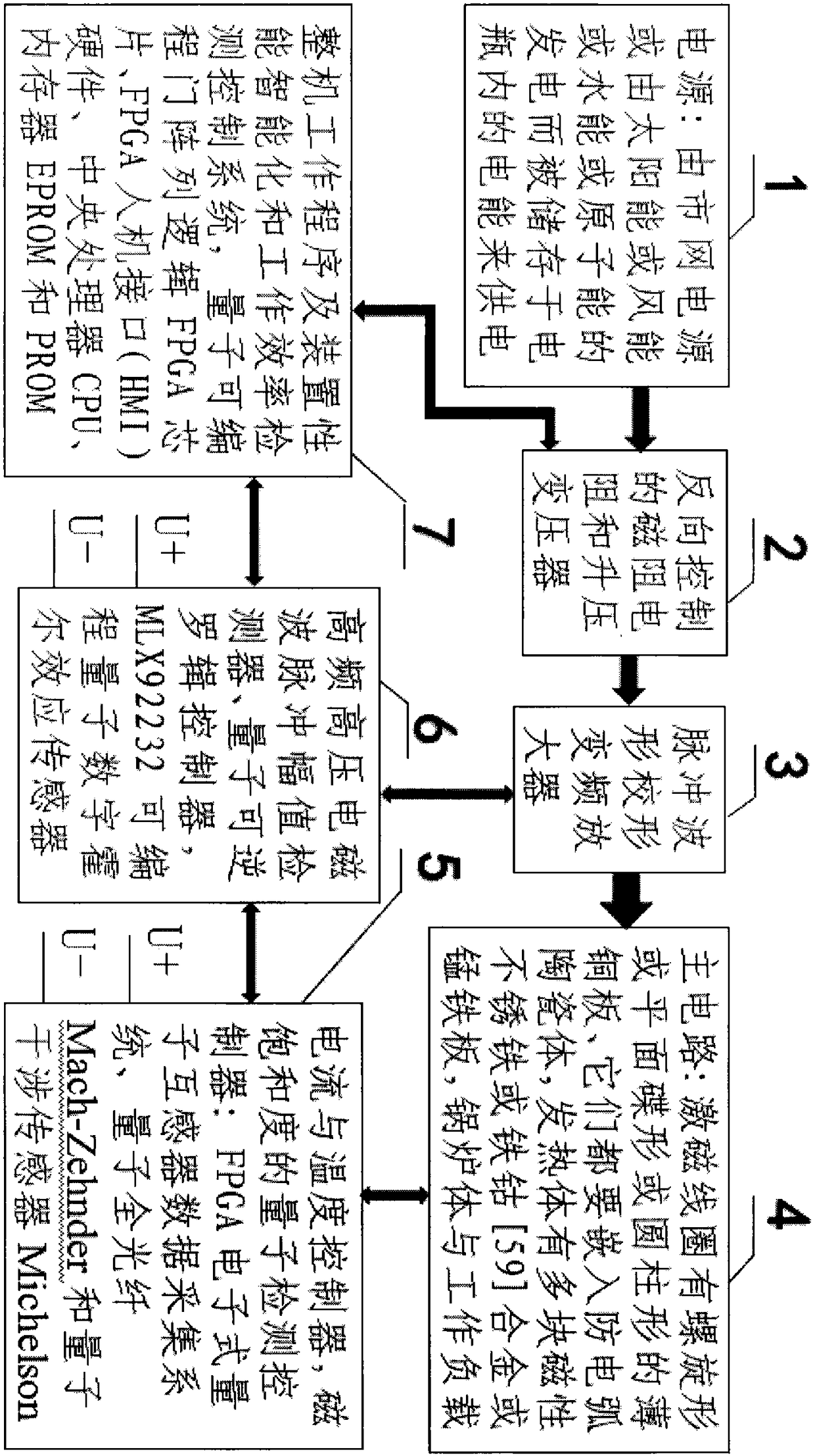

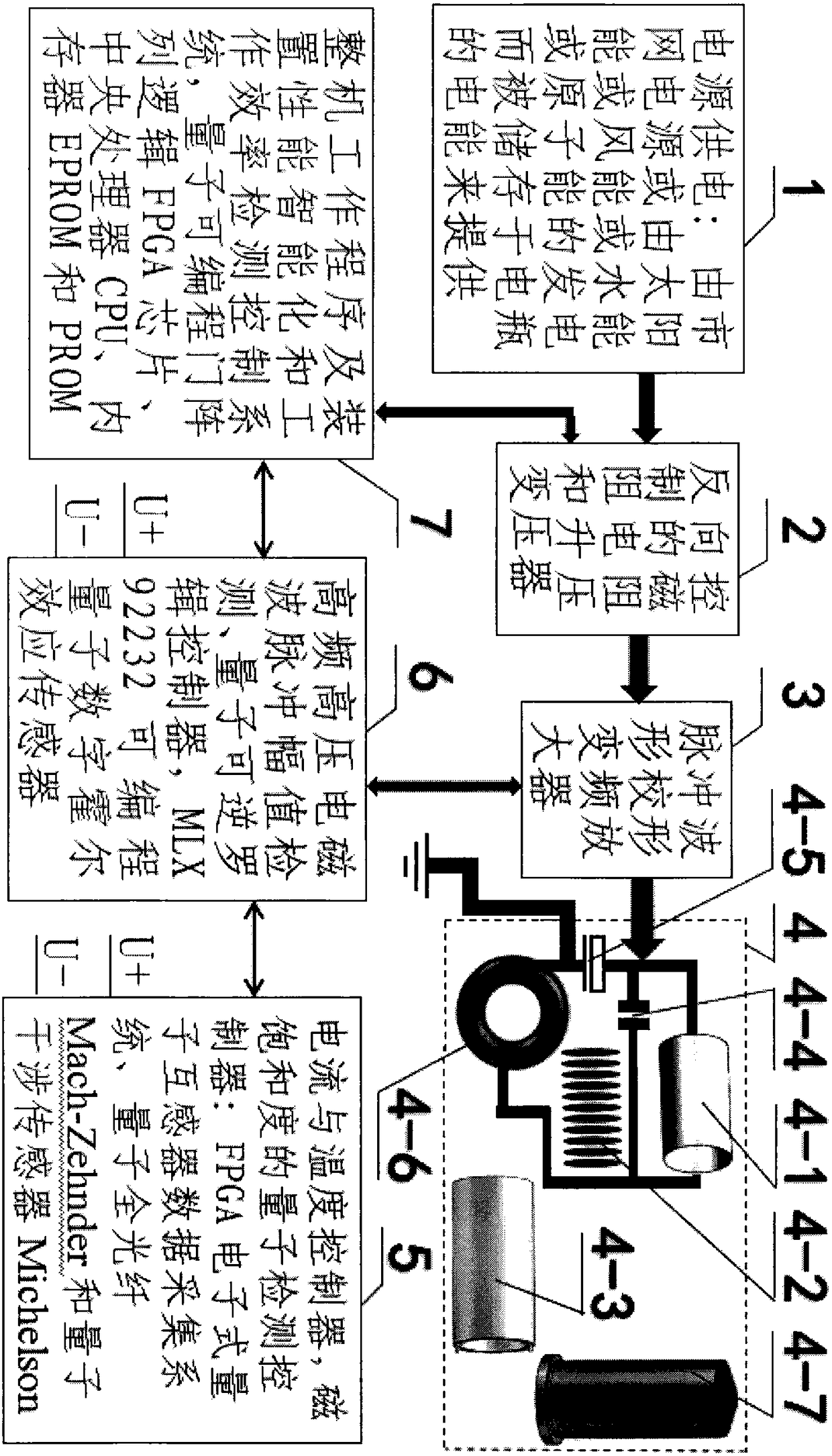

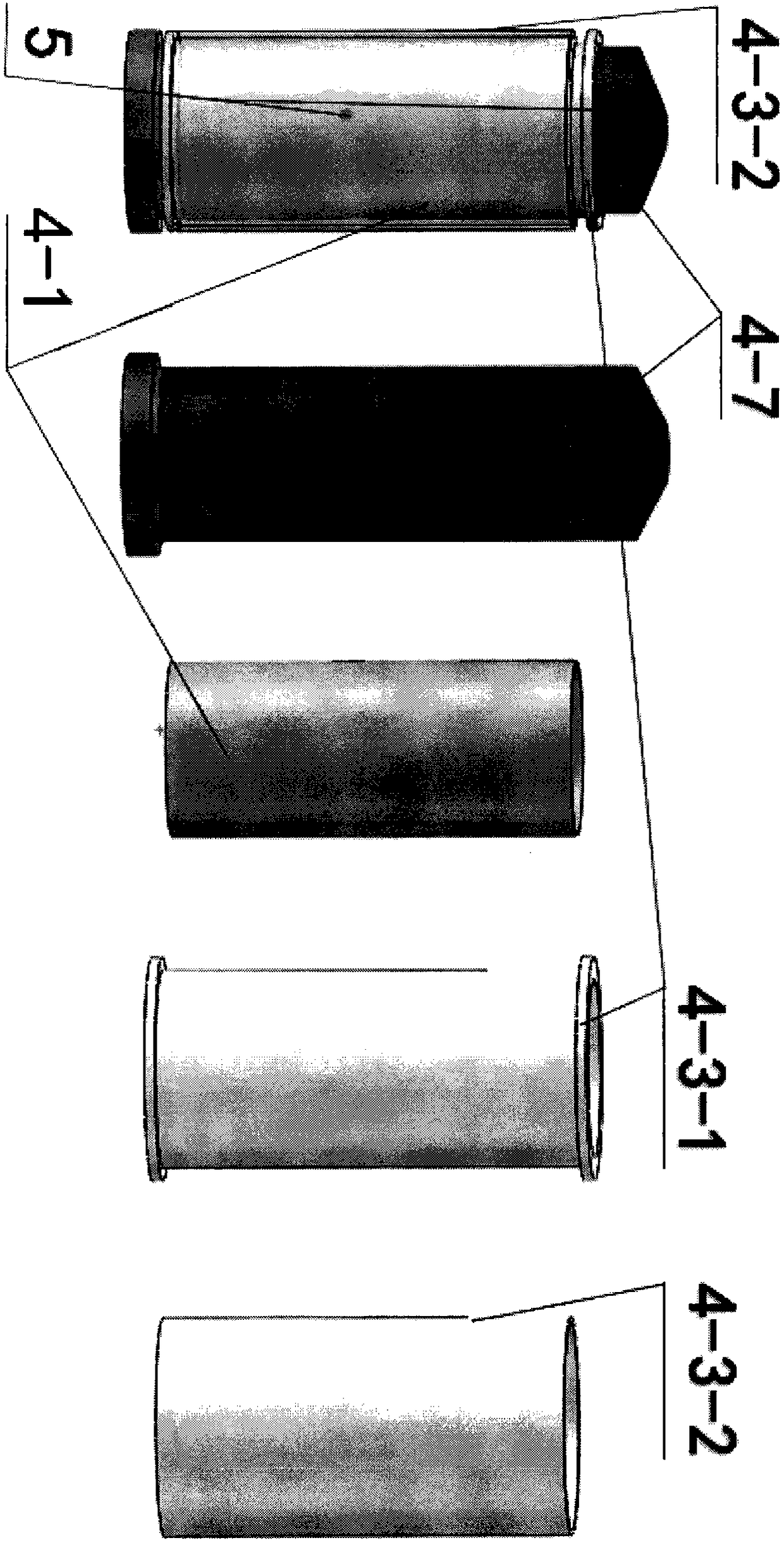

[0038] The present invention uses a pulse waveform correction frequency conversion amplifier and a 'non-operating frequency high-order harmonic device' and a main circuit are set in it: the exciting coil has a thin ring-shaped cylindrical copper plate or a spiral or a plane butterfly or their Both are embedded in the arc-proof ceramic body, the heating body is a plurality of magnetic stainless iron or iron-cobalt [59] alloy or manganese-iron plates, the boiler body and the working load are used to effectively increase its actual heating area technology, current and temperature control Sensor, magnetic saturation quantum detection controller: FPGA electronic quantum transformer data acquisition system, quantum all-fiber Mach-Zehnder and quantum interference sensor Michelson intelligent system to strengthen the "eddy current" to achieve its unprecedented high efficiency and energy saving zero Carbon-free combustion, environmental protection, excellent safety and reliability, non-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com