Preparation method and application of vernonia amygdalina saponin

A technology of almond vernonia saponin and almond leaf spot, applied in the field of natural medicinal chemistry, can solve the problems of large consumption of organic solvents, difficulty in mass production, etc., and achieve the effect of improving purity and reducing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

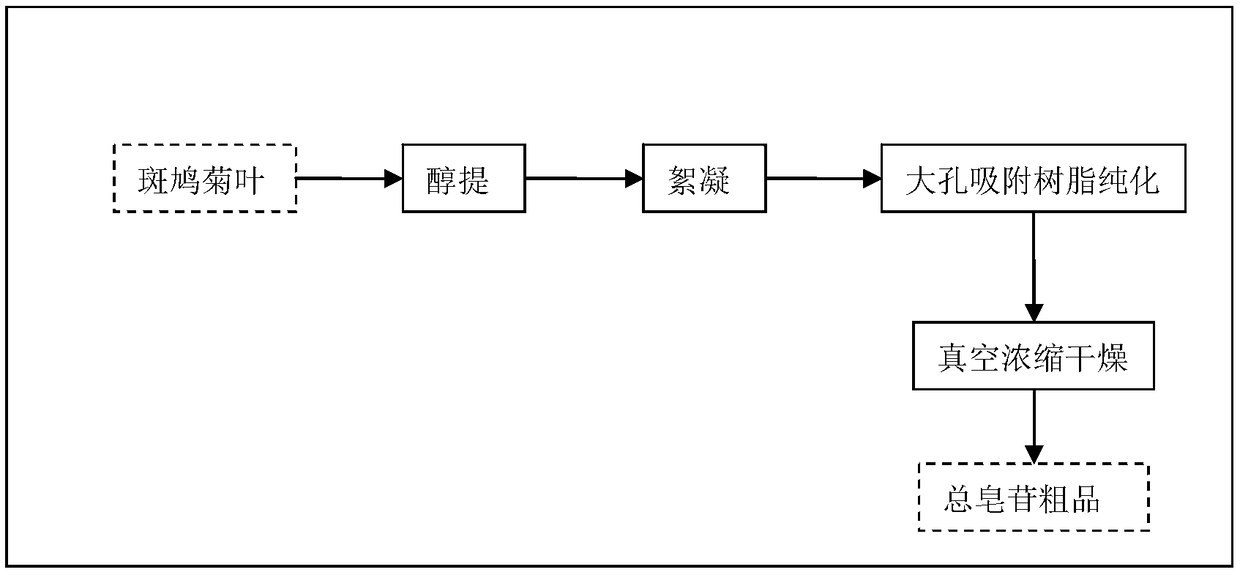

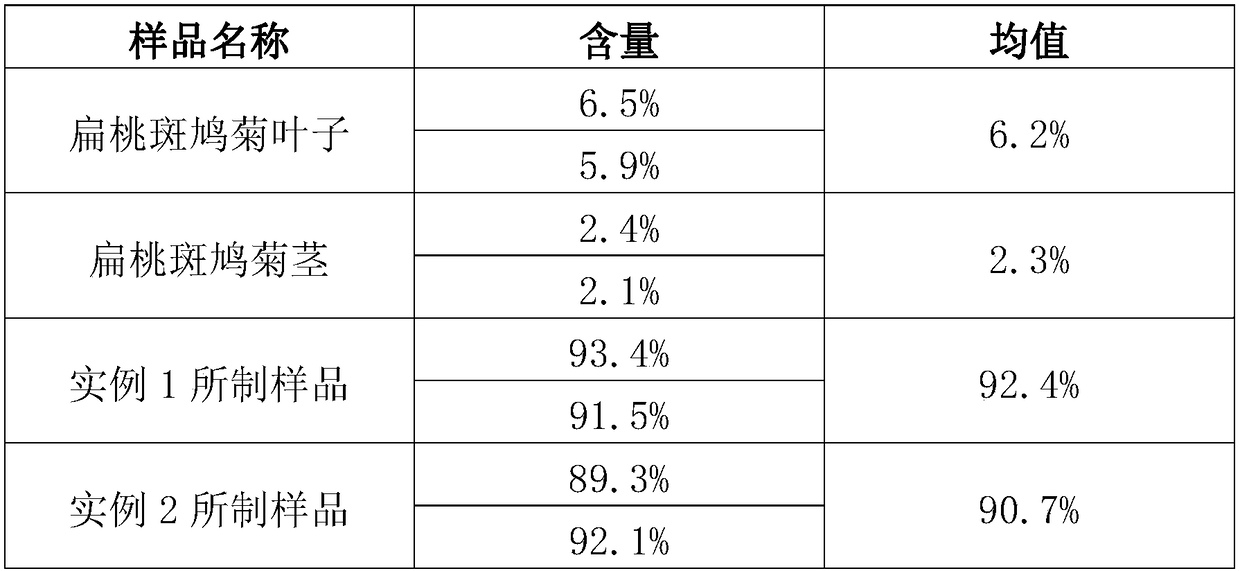

[0050] Embodiment 1: the preparation of almond vernonia total saponins, such as figure 1 :

[0051] (1) extraction

[0052] Take 1 kg of dried Vernonia amygdala leaves, crush them, and extract them with 3 times 40% alcohol at a temperature of 60°C for 1.5 hours; filter and collect the filtrate. Leach twice to obtain a total of about 5L of extract.

[0053] (2) Flocculation

[0054] Heat the extract so that its temperature is 60°C, add 24mL 5% polyaluminum chloride solution to the extract, stir and mix quickly; then add 300mL 1% chitosan solution to the solution, stir and mix quickly, and finally use 5% Sodium carbonate solution was used to adjust the pH to 6; after standing for 2 hours, it was filtered and the filtrate was collected.

[0055] (3) refined

[0056] The above-mentioned filtrate is passed through the AB-8 macroporous adsorption resin column, and the control flow rate is 2-3BV / h; then use 1.5BV containing 25% alcohol (containing 0.3% sodium carbonate) to elute t...

Embodiment 2

[0059] Embodiment 2: Preparation of total saponins of Vernonia amygdala

[0060] (1) extraction

[0061] Take 500g of dried Vernonia amygdala leaves, crush them, extract with 4 times of 30% alcohol, the extraction temperature is 65°C, and the extraction time is 2 hours; filter and collect the filtrate. Leaching twice, a total of about 3.5L of extract was obtained.

[0062] (2) Flocculation

[0063] Heat the extract to 60°C, add 21mL of 5% polyferric chloride solution, stir and mix quickly, and filter; then add 350mL of 0.5% polyacrylamide solution to the filtrate, stir and mix quickly, and finally add 5% sodium carbonate The pH of the solution was adjusted to 6; after standing for 2 hours, it was filtered and the filtrate was collected.

[0064] (3) refined

[0065] The above-mentioned filtrate is passed through the AB-8 macroporous adsorption resin column, and the control flow rate is 2-3BV / h; then use 1.5BV containing 30% alcohol (containing 0.2% sodium carbonate) to elu...

Embodiment 3

[0068] Example 3 Antibacterial and anti-acne essence preparation

[0069] Phase A: 2.0g total vernonia saponins, 10.0g butanediol, 1.0g tea tree oil, 0.5g Tween-80 phenoxyethanol 0.05g; phase B: 80ml water, 20.0g 1% hyaluronic acid, 5.0g glycerin and mix well ; Phase A and Phase B are heated and dissolved first, and then the two are mixed and stirred to obtain the antibacterial and anti-inflammatory essence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com