Method for preparing three-dimensional mineralized collagen scaffold material with hierarchical structure

A technology for mineralizing collagen and scaffolding materials, applied in the field of materials, can solve problems such as unexplainable hierarchical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

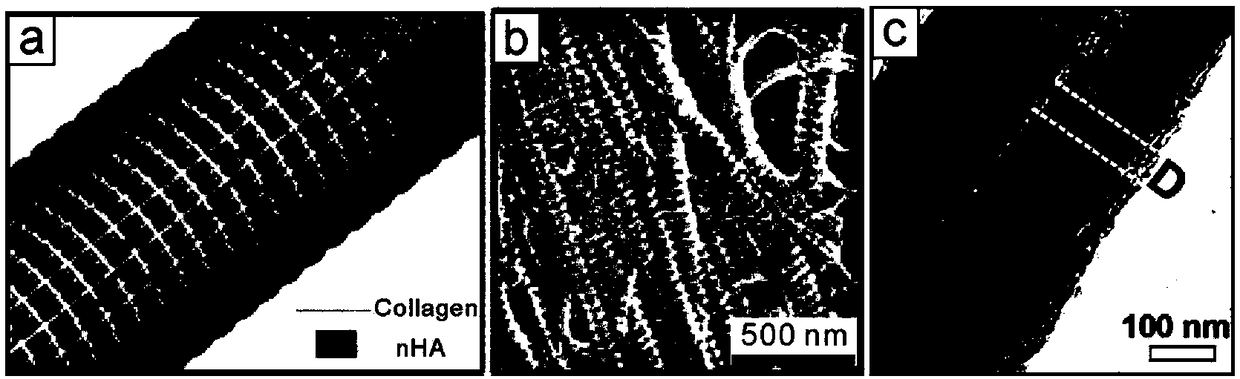

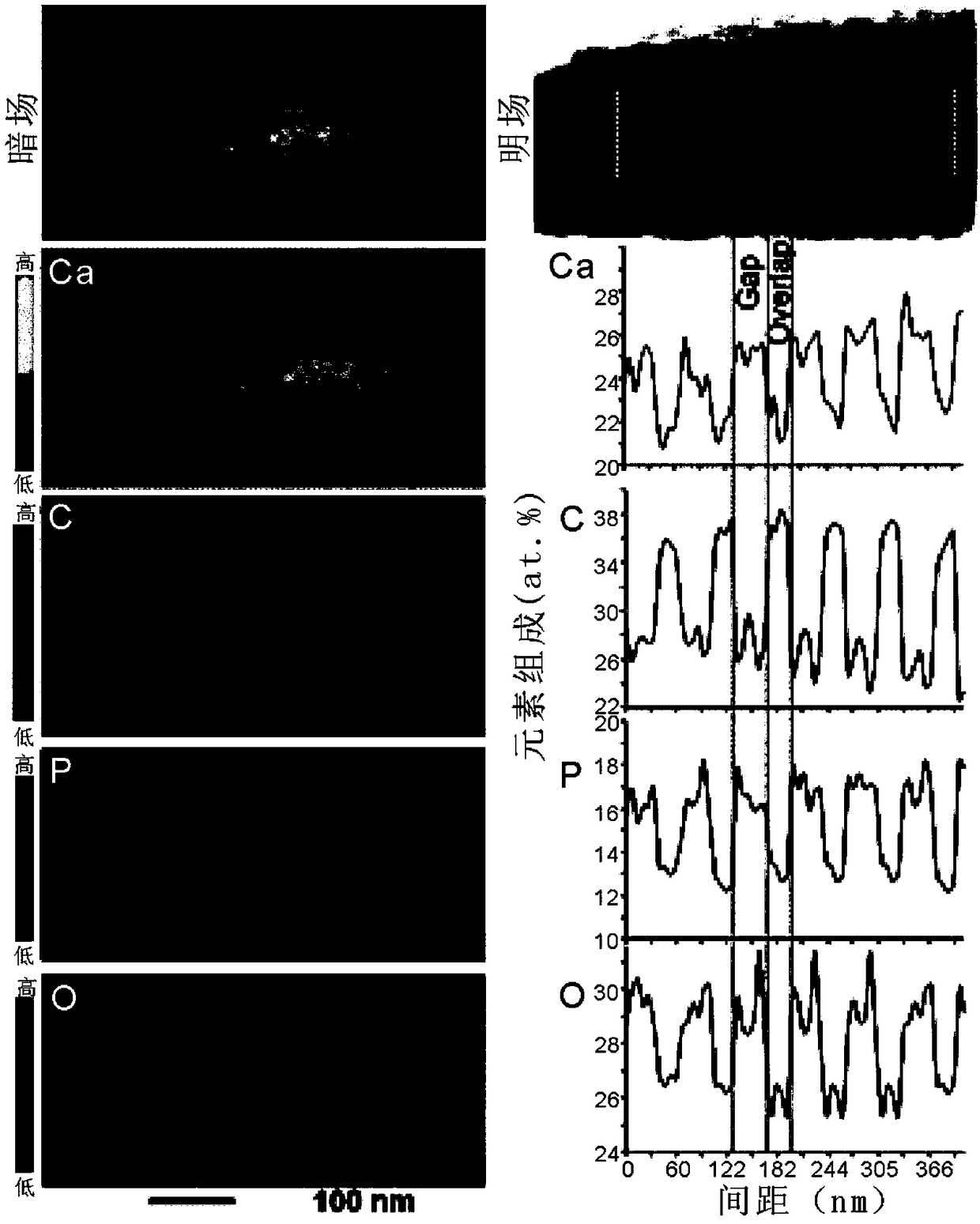

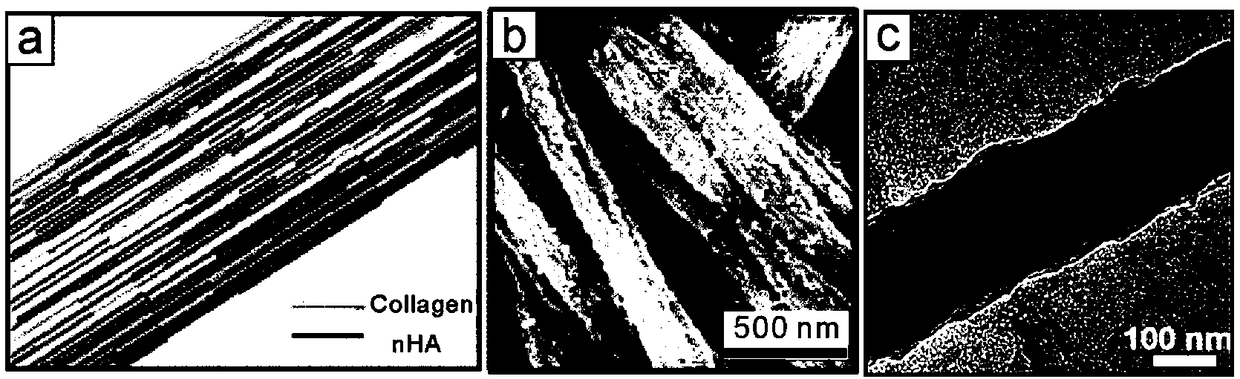

Method used

Image

Examples

Embodiment 1

[0035] A preparation of a three-dimensional mineralized collagen scaffold material with a multi-level structure, including the following raw materials and procurement sources: rat tail type I procollagen solution (BD Bio-sciences), dialysis bag (3500Da, Invitrogen, Paisly, UK), PAA ( M.W.72, 2000, 5000) (Sigma-Aldrich, USA), phosphate buffer (Gibco, Invitrogen, Paisly, UK) and glycine (Sigma-Aldrich, USA).

[0036] The method for preparing a three-dimensional mineralized collagen scaffold material with a multi-level structure; the specific steps are as follows:

[0037] (1) Configuration of phosphate buffer: weigh 8g of NaCl, 0.2g of KCl, 3g of Na2HPO4, 0.29g of Ka 2 HPO 4 ·3H 2 O and 0.2g of Na3N were dissolved in 1L of deionized water, and the pH of the solution was adjusted to 7.4 with NaOH and HCl;

[0038] (2) Collagen mineralization: The dialysis bag (molecular weight cut off: 3500) filled with 10.6 mL of 9.46 mg / mL rat tail type I procollagen solution was immersed in...

Embodiment 2

[0042] A preparation of a three-dimensional mineralized collagen scaffold material with a multi-level structure, including the following raw materials and procurement sources: rat tail type I procollagen solution (BD Bio-sciences), dialysis bag (3500Da, Invitrogen, Paisly, UK), PAA ( M.W.72, 2000, 5000) (Sigma-Aldrich, USA), phosphate buffer (Gibco, Invitrogen, Paisly, UK) and glycine (Sigma-Aldrich, USA).

[0043] The method for preparing a three-dimensional mineralized collagen scaffold material with a multi-level structure; the specific steps are as follows:

[0044] (1) Configuration of phosphate buffer: weigh 8g of NaCl, 0.2g of KCl, 3g of Na2HPO4, 0.29g of Ka 2 HPO 4 ·3H 2 O and 0.2g of Na3N were dissolved in 1L of deionized water, and the pH of the solution was adjusted to 7.4 with NaOH and HCl;

[0045] (2) Collagen mineralization: The dialysis bag (molecular weight cut off: 3500) filled with 10.6 mL of 9.46 mg / mL rat tail type I procollagen solution was immersed in...

Embodiment 3

[0049] A preparation of a three-dimensional mineralized collagen scaffold material with a multi-level structure, including the following raw materials and procurement sources: rat tail type I procollagen solution (BD Bio-sciences), dialysis bag (3500Da, Invitrogen, Paisly, UK), PAA ( M.W.72, 2000, 5000) (Sigma-Aldrich, USA), phosphate buffer (Gibco, Invitrogen, Paisly, UK) and glycine (Sigma-Aldrich, USA).

[0050] The method for preparing a three-dimensional mineralized collagen scaffold material with a multi-level structure; the specific steps are as follows:

[0051] (1) Configuration of phosphate buffer: Weigh 8g of NaCl, 0.2g of KCl, 3g of Na2HPO4, 0.29g of Ka2HPO4 3H2O, 0.2g of Na3N and dissolve them in 1L of deionized water, adjust the pH of the solution with NaOH and HCl in 7.4;

[0052] (2) Collagen mineralization: The dialysis bag (molecular weight cut off: 3500) filled with 10.6 mL of 9.46 mg / mL rat tail type I procollagen solution was immersed in 30 mL of phosphat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com