Heating method of electronic grade hydrofluoric acid distillation system

A technology of electronic grade hydrofluoric acid and distillation system, which is applied in the heating field of electronic grade hydrofluoric acid distillation system, can solve the problems of high temperature of steam condensed water, large temperature difference between heat medium and medium, and difficult control, so as to achieve circulation Effects of utilization, waste reduction, and ease of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

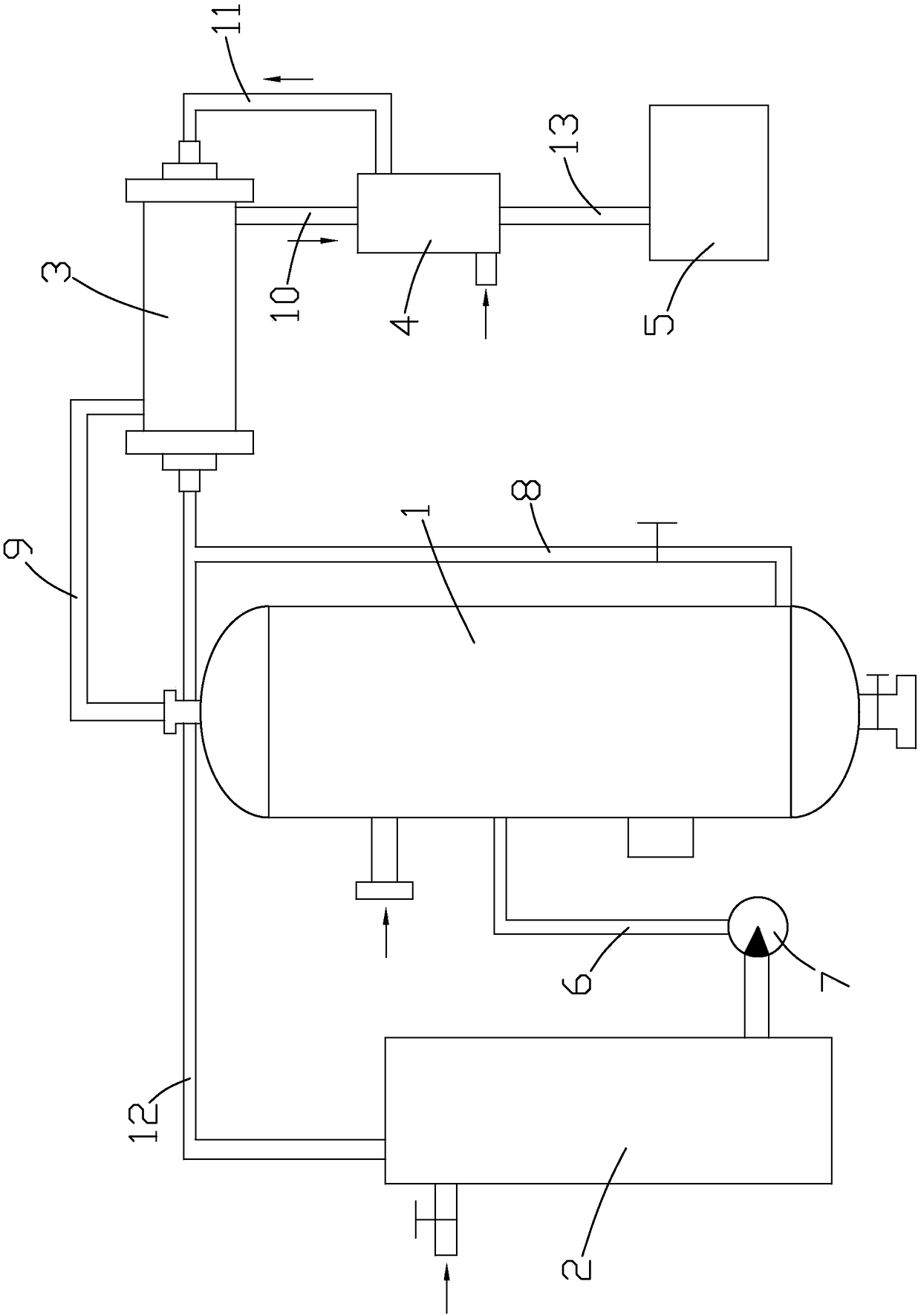

[0036] Such as Figure 1 to Figure 5 Shown, be the heating method of a kind of electronic grade hydrofluoric acid distillation system of the present invention, comprise the following steps:

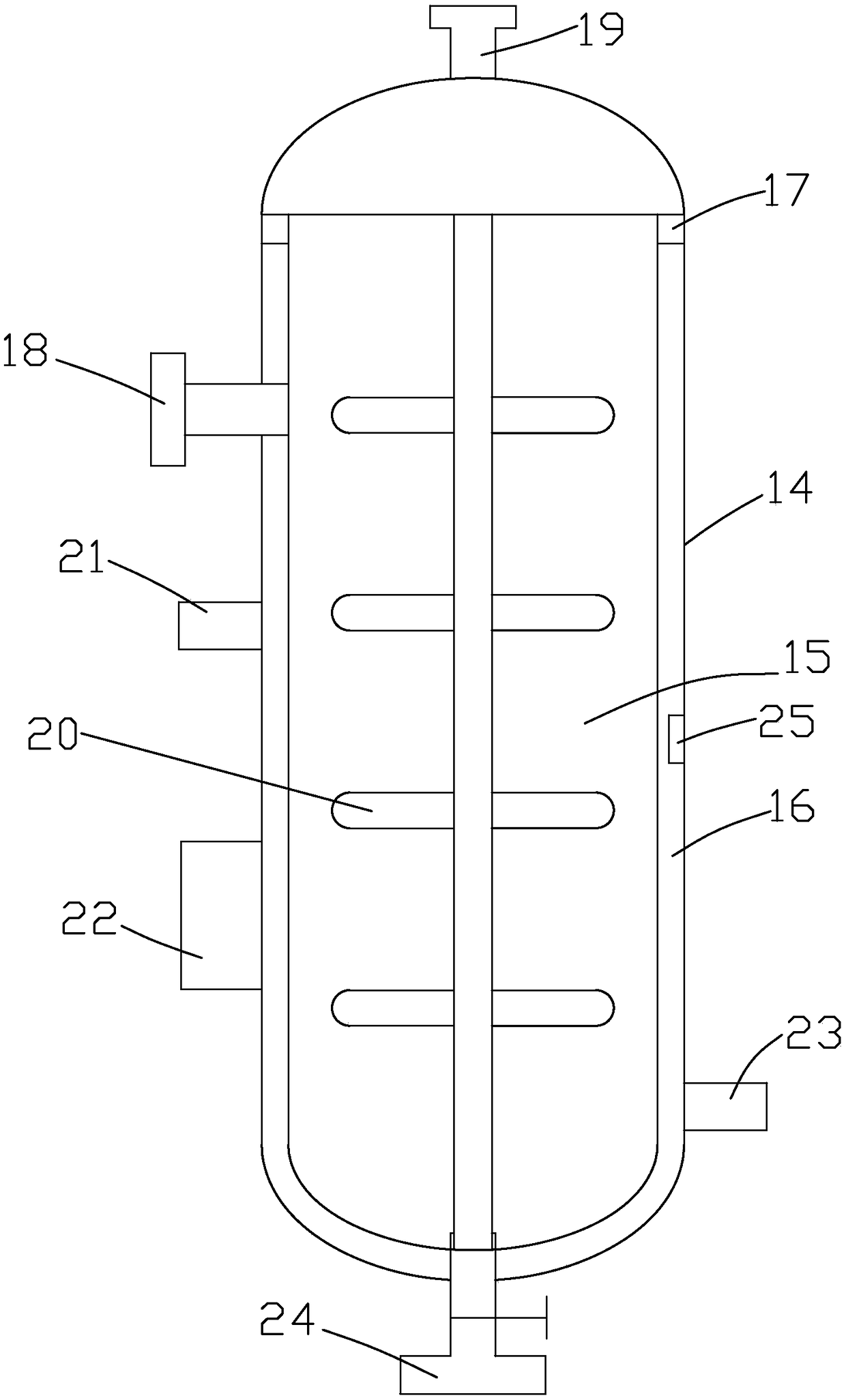

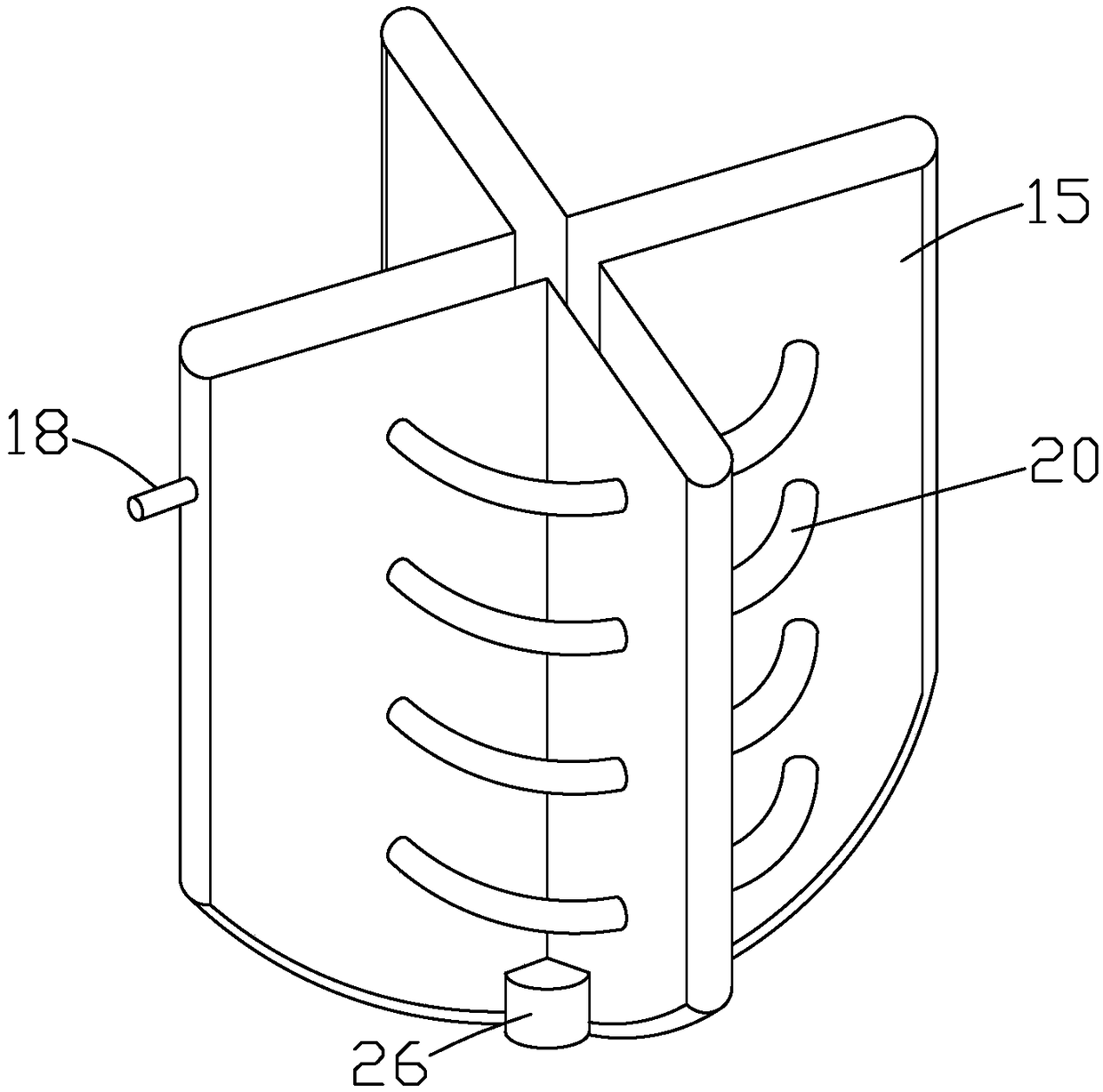

[0037] a. First, the ordinary hydrogen fluoride solution is continuously passed into the distillation inner tank 15 through the liquid inlet port 18 on the distillation tower 1, and the distillation inner tank 15 is fixedly connected in the first tower body 14 through the limit plate 17, so that the ordinary hydrogen fluoride solution is The distance between the liquid level in the distillation liner 15 and the top of the distillation liner 15 is 20-30 cm, stop feeding the common hydrogen fluoride solution;

[0038]Limiting plate 17 is provided with limit card groove 27, the cross section of limit card groove 27 and the cross section of distillation liner 15 are cross-shaped structure, distillation liner 15 matches limit card groove 27, limit plate 17 can fix the distillation liner 15 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com