Method for preparing graphene/nickel-iron hydrotalcite nano-sheet bifunctional oxygen catalyst by one-step process

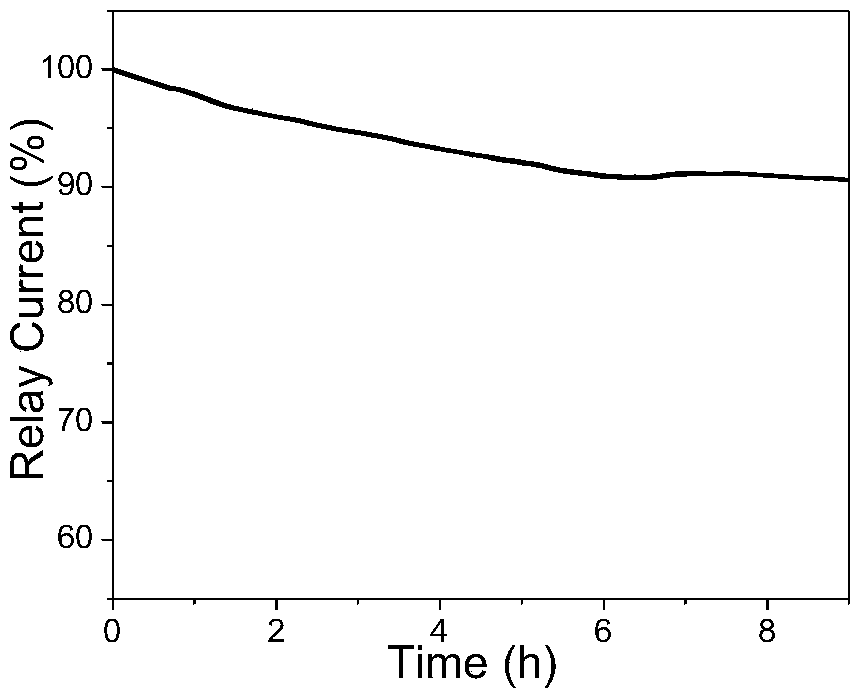

An oxygen catalyst, graphene technology, applied in the field of electrocatalysis, to achieve the effects of improved stability, low price, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

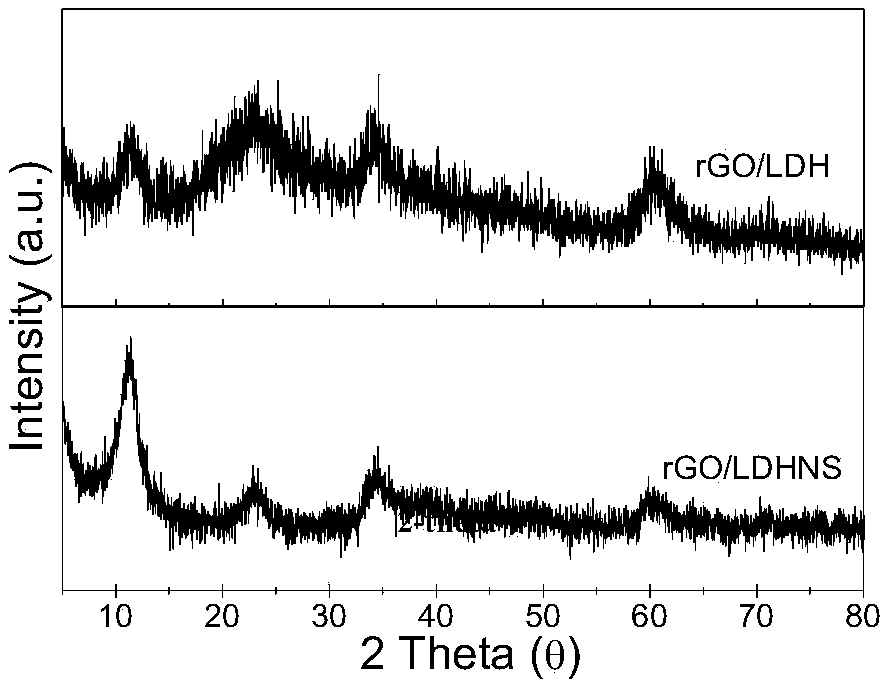

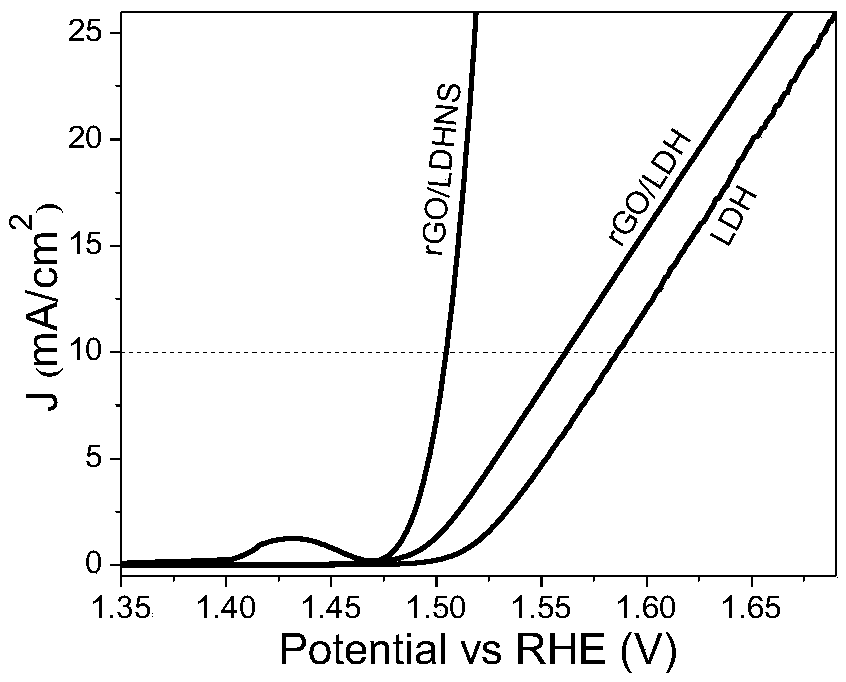

[0025] Take a certain amount of graphene oxide GO and ultrasonically disperse it in 100mL aqueous solution containing 50% formamide to make the concentration 0.3mg / mL, add nickel nitrate hexahydrate and ferric nitrate nonahydrate to it at a molar ratio of 2:1, Make the total metal ion concentration 0.03mol / L, stir for 1h to completely dissolve the metal salt, and slowly titrate with 0.7mol / L sodium hydroxide aqueous solution containing 50% formamide until the pH of the reaction solution is about 8.5 under the condition of vigorous stirring ~9.5, move the mixed solution into a reaction kettle and react at 140°C for 8 hours. After cooling, the reaction solution is centrifuged at 4000rpm, washed with deionized water and ethanol for 3 times, and dried to obtain graphene / nickel-iron hydrotalcite nanoparticles. Sheet complex, denoted as rGO / LDHNS.

Embodiment 2

[0027] Take a certain amount of graphene oxide GO and ultrasonically disperse it in 100mL aqueous solution containing 40% formamide to make the concentration 0.1mg / mL, add nickel nitrate hexahydrate and ferric nitrate nonahydrate to it at a molar ratio of 2:1, Make the total metal ion concentration 0.03mol / L, stir for 1h to completely dissolve the metal salt, and slowly titrate with 0.7mol / L sodium hydroxide aqueous solution containing 40% formamide until the pH of the reaction solution is about 8.5 under the condition of vigorous stirring ~9.5, move the mixed solution into the reaction kettle and react at 120°C for 10h. After cooling, the reaction solution is centrifuged at 4000rpm, washed with deionized water and ethanol for 3 times, and dried to obtain graphene / nickel-iron hydrotalcite nanometer Sheet complex, denoted as rGO / LDHNS.

Embodiment 3

[0029]Take a certain amount of graphene oxide GO and ultrasonically disperse it in 100mL aqueous solution containing 60% formamide to make the concentration 0.5mg / mL, add nickel nitrate hexahydrate and ferric nitrate nonahydrate to it at a molar ratio of 2:1, Make the total metal ion concentration 0.03mol / L, stir for 1h to completely dissolve the metal salt, and slowly titrate with 0.7mol / L sodium hydroxide aqueous solution containing 60% formamide until the pH of the reaction solution is about 8.5 under the condition of vigorous stirring ~9.5, move the mixed solution into a reaction kettle and react at 150°C for 8 hours, after cooling, the reaction solution is centrifuged at 4000rpm, washed with deionized water and ethanol for 3 times, and dried to obtain graphene / nickel-iron hydrotalcite nanometer Sheet complex, denoted as rGO / LDHNS.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com