Method for preparing high-performance activated carbon by one-step pyrolysis of biomass with low pressure in a tubular furnace

A tube furnace and biomass technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of good adsorption performance of products, not harsh process conditions, low equipment requirements, etc., and achieve low cost and high adsorption performance Good, the effect of no loss of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

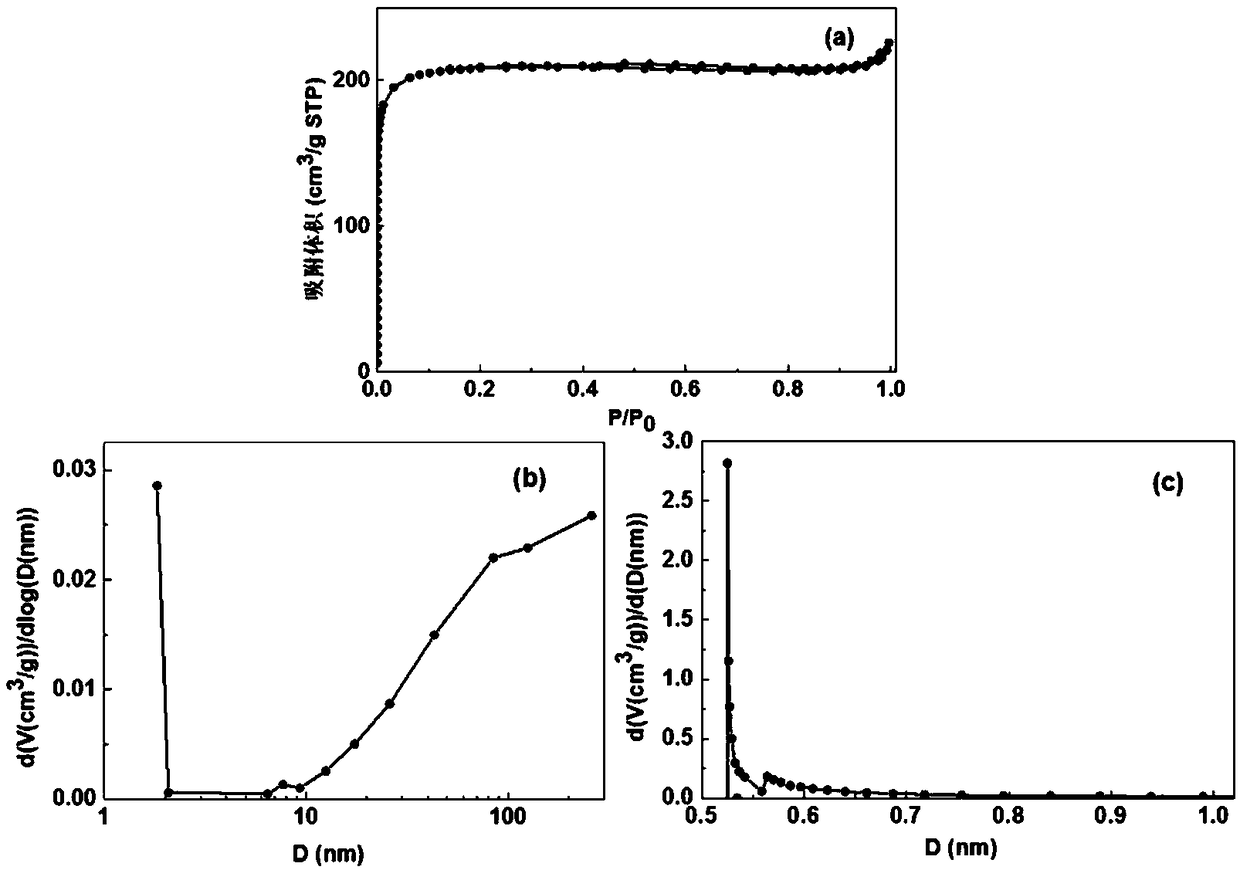

Embodiment 1

[0024] (1) Raw material crushing: crush the air-dried walnut shell raw material, sieve, take 1.00-1.18mm particles, and dry at 120°C.

[0025] (2) Vacuum treatment before reaction: Put the corundum boat containing 9g of walnut shell raw materials into the middle of the tube furnace, close the valve at the inlet of the tube furnace, evacuate the inside of the tube to vacuum (<1Kpa) through the outlet valve, and close the outlet valve , Observe the pressure in the furnace through the pressure gauge at the entrance.

[0026] (3) Pyrolysis activation: heat up to a pyrolysis temperature of 900°C at a heating rate of 5°C / min. During the heating process, when the pressure in the furnace reaches 0.12MPa, adjust the outlet valve to control the pressure in the furnace to always be at 0.12Mpa, and keep warm for 6h After the pyrolysis is over, take out the sample, wash it with water until neutral, and dry it to become the activated carbon sample. The yield of activated carbon is 24.2%, a...

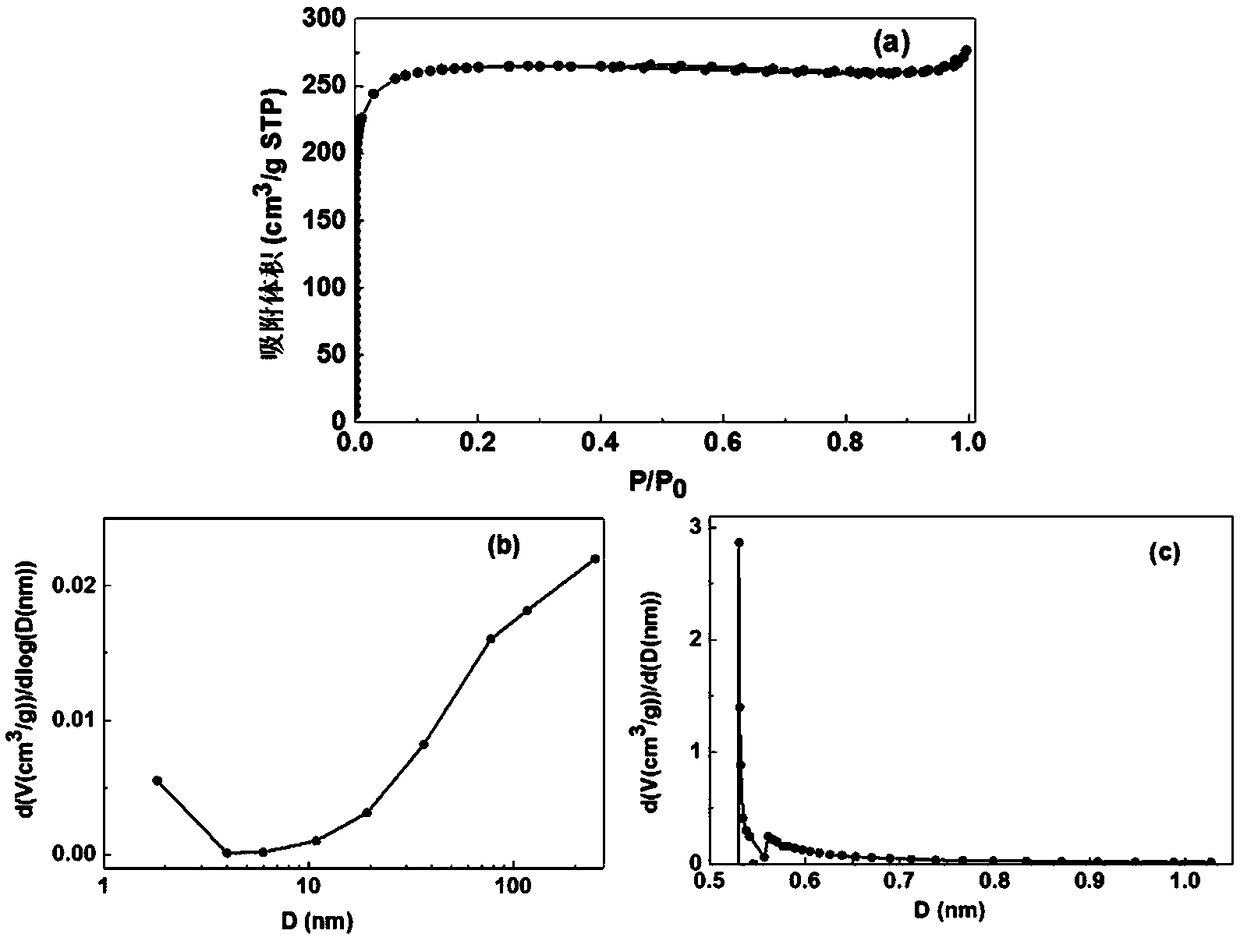

Embodiment 2

[0028] (1) Raw material crushing: crush the air-dried coconut shell raw material, sieve, take 1.00-1.18mm particles, and dry at 120°C.

[0029] (2) Vacuum treatment before reaction: Put the corundum boat with 9g coconut shell raw material into the middle of the tube furnace, close the valve at the inlet of the tube furnace, pump the inside of the tube to vacuum (<1Kpa) through the outlet valve, and close the outlet valve , Observe the pressure in the furnace through the pressure gauge at the entrance.

[0030] (3) Pyrolysis activation: heat up to a pyrolysis temperature of 900°C at a heating rate of 5°C / min. During the heating process, when the pressure in the furnace reaches 0.12MPa, adjust the outlet valve to control the pressure in the furnace to always be at 0.12Mpa, and keep warm for 6h After the pyrolysis is over, take out the sample, wash it with water until neutral, and dry it to become the activated carbon sample. The yield of activated carbon is 19.3%, and the speci...

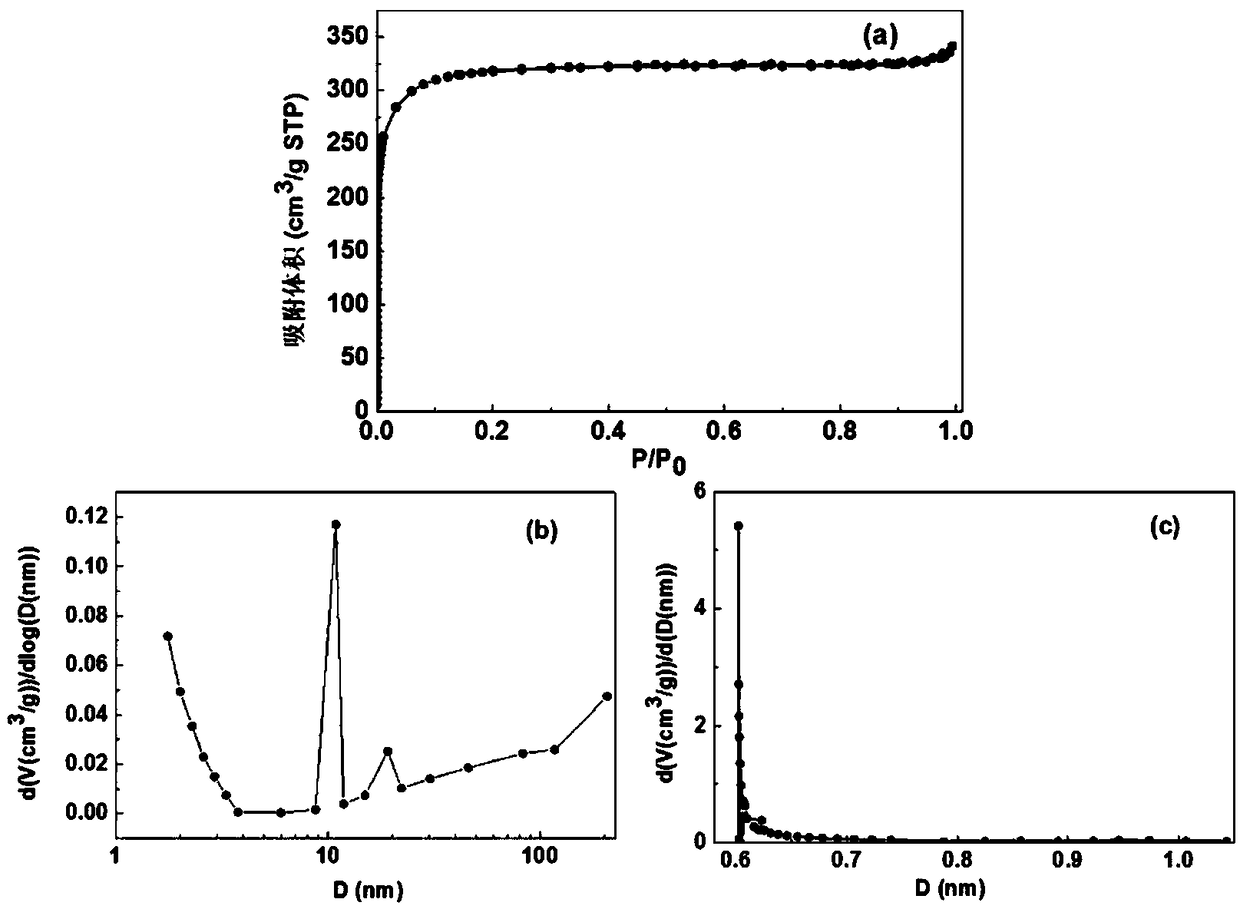

Embodiment 3

[0032] (1) Raw material crushing: crush the air-dried coconut shell raw material, sieve, take 1.00-1.18mm particles, and dry at 120°C.

[0033] (2) Vacuum treatment before reaction: Put the corundum boat with 9g coconut shell raw material into the middle of the tube furnace, close the valve at the inlet of the tube furnace, pump the inside of the tube to vacuum (<1Kpa) through the outlet valve, and close the outlet valve , Observe the pressure in the furnace through the pressure gauge at the entrance.

[0034] (3) Pyrolysis activation: heat up to a pyrolysis temperature of 900°C at a heating rate of 5°C / min. During the heating process, when the pressure in the furnace reaches 0.1MPa, adjust the outlet valve to control the pressure in the furnace to always be at 0.1Mpa, and keep warm for 6h After the pyrolysis is over, take out the sample, wash it with water until neutral, and dry it to become the activated carbon sample. The yield of activated carbon is 20.2%, the adsorption ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com