Activated persulfate, method for degrading pollutants, and application of EDTA-VC

A technology for activating persulfate and persulfate, applied in the field of pollutant treatment, can solve the problems of refractory degradation effect, high treatment cost, and inability to remove nitrate nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1) Selection of iron ion source:

[0053] The source of ferrous iron selected in this embodiment is ferrous sulfate heptahydrate.

[0054] 2) Selection of persulfate:

[0055] The persulfate selected in this embodiment is sodium persulfate.

[0056] 3) Choice of complexing agent: ascorbic acid, EDTA

[0057] 4) The specific degradation process is implemented according to the following steps:

[0058] Get the p-chlorophenol aqueous solution (concentration is 20mg / L) in the scope of adjusting pH value 5-6, add EDTA: ascorbic acid: Fe 2 + : The molar ratio of sodium persulfate is 0.1:4:3:25, the total volume is 50ml, and the reaction degradation is carried out at 15°C and shaken at 200rpm for 5min;

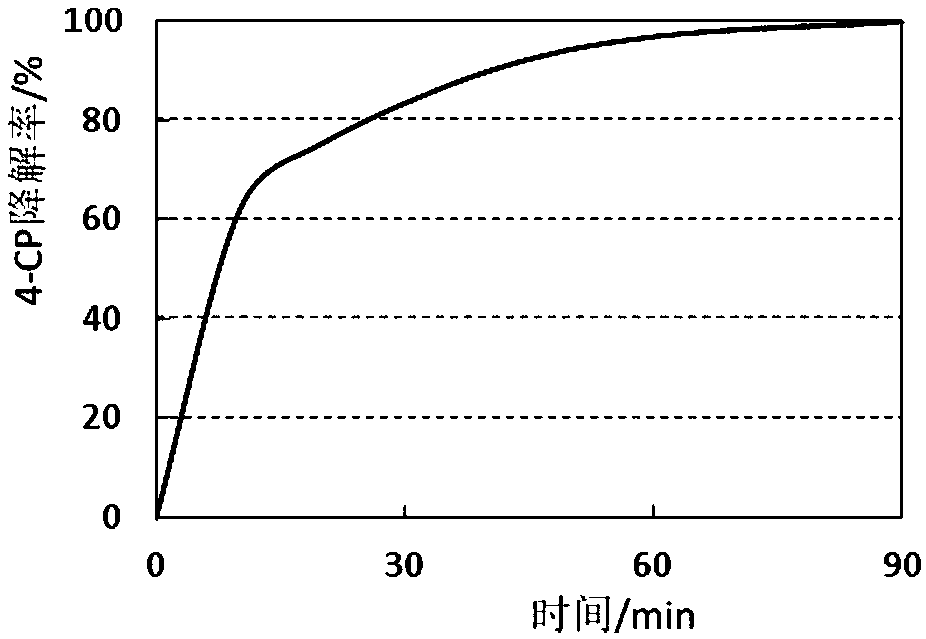

[0059] Take 3ml of the degraded solution in a 10ml centrifuge tube, extract with an equal volume of ethyl acetate, pass through a 0.22um water filter membrane, and use HPLC to detect that the degradation rate of p-chlorophenol (4-CP) is 92% for 20 minutes. The reaction s...

Embodiment 2

[0061] 1) Selection of iron ion source:

[0062] The source of ferrous iron selected in this embodiment is ferrous acetate and ferrous sulfate heptahydrate.

[0063] 2) Selection of persulfate:

[0064] The persulfate selected in this embodiment is sodium persulfate.

[0065] 3) Choice of complexing agent: ascorbic acid, EDTA

[0066] 4) The specific degradation process is implemented according to the following steps:

[0067] Get and adjust the p-chlorophenol aqueous solution (concentration is 20mg / L) in the scope of pH value 4-5, add EDTA: ascorbic acid: Fe 2 + : The molar ratio of sodium persulfate is 3:0.2:20:5, the total volume is 50ml, and the reaction degradation is carried out at 50°C and shaken at 210rpm for 30min;

[0068]Take 3ml of the degraded solution in a 10ml centrifuge tube, extract with an equal volume of ethyl acetate, pass through a 0.22um water filter membrane, and use HPLC to detect that the degradation rate of p-chlorophenol (4-CP) is 90% for 20 min...

Embodiment 3

[0070] 1) Selection of iron ion source:

[0071] The source of ferrous iron selected in this embodiment is ferrous chloride tetrahydrate.

[0072] 2) Selection of persulfate:

[0073] The persulfates selected in this embodiment are potassium persulfate and sodium persulfate.

[0074] 3) Choice of complexing agent: ascorbic acid, EDTA

[0075] 4) The specific degradation process is implemented according to the following steps:

[0076] Get and adjust the p-chlorophenol aqueous solution (concentration is 20mg / L) in the scope of pH value 2-4, add EDTA: ascorbic acid: Fe 2 + : The molar ratio of sodium persulfate is 0.5:1.5:7:10, the total volume is 50ml, and the reaction degradation is carried out at 30°C and shaken at 250rpm for 10min;

[0077] Take 3ml of the degraded solution in a 10ml centrifuge tube, extract with an equal volume of ethyl acetate, pass through a 0.22um water filter membrane, and use HPLC for 20min to detect that the degradation rate of p-chlorophenol (4-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com